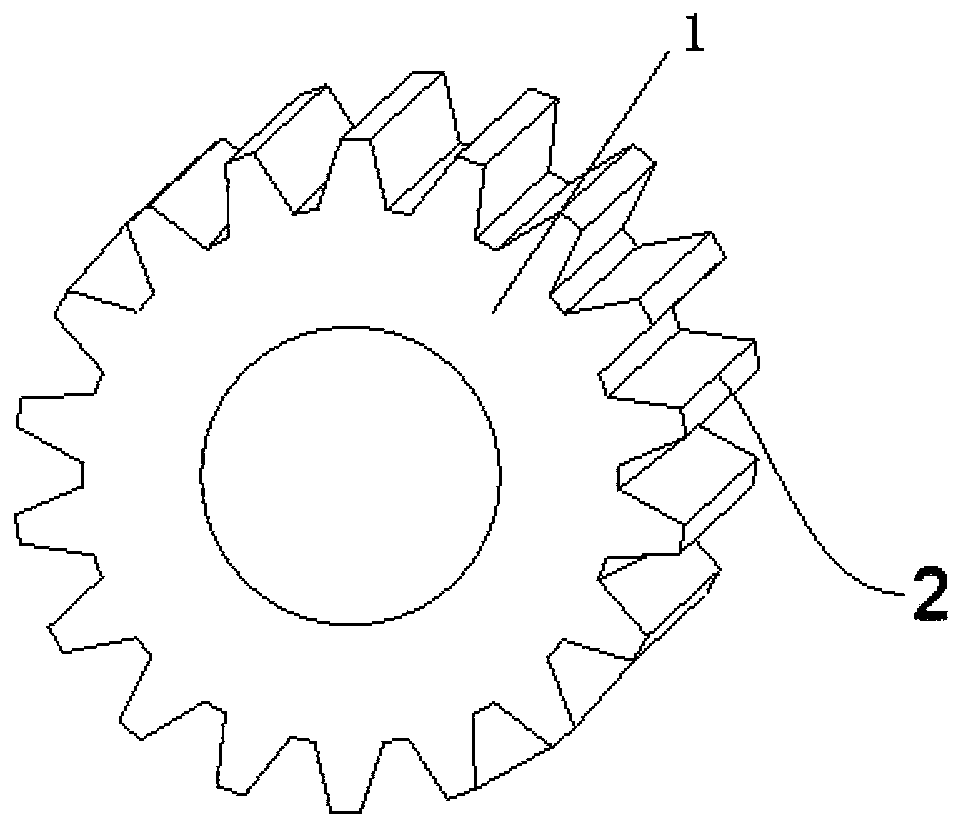

Low-noise self-lubrication small and medium modulus cylindrical gear and preparation method thereof

A small and medium modulus, cylindrical gear technology, applied in the field of gear processing, can solve problems such as wear, poor self-lubricating performance of cylindrical gears, large vibration and noise vibration, etc., to achieve uniform as-cast structure, uniform mechanical properties, and long heat preservation time shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

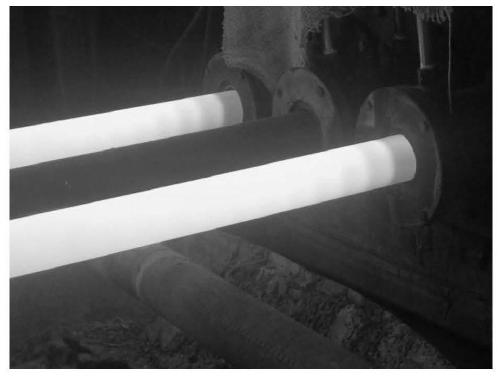

[0063] According to the mechanical properties of the ultra-fine ADI to be produced, select the QT500-10 brand, and draw a bar with an outer diameter of 100mm, and process it into a small and medium modulus cylindrical gear.

[0064] A method for preparing a low-noise self-lubricating medium and small modulus cylindrical gear of the present invention comprises the following steps:

[0065] The casting materials (60% Q14# bread iron, 20% low carbon steel leftovers, 20% nodular iron return material) are melted into molten iron in an intermediate frequency induction furnace, and adjusted to the mass percentage of the following components: C: 3.50±0.05 %, Si: 1.40±0.05%, Mn: ≤0.3%, P: ≤0.015%, S: ≤0.015%, Cr: 0.3-0.5%, Cu: 0.5-1.0%, Ni: 0.5-1.0%, other alloys Elements: ≤0.3%, the balance is Fe, the sum of the mass percentages of the above components is 100%, and the carbon content is 99.95%-100% of the theoretical carbon equivalent.

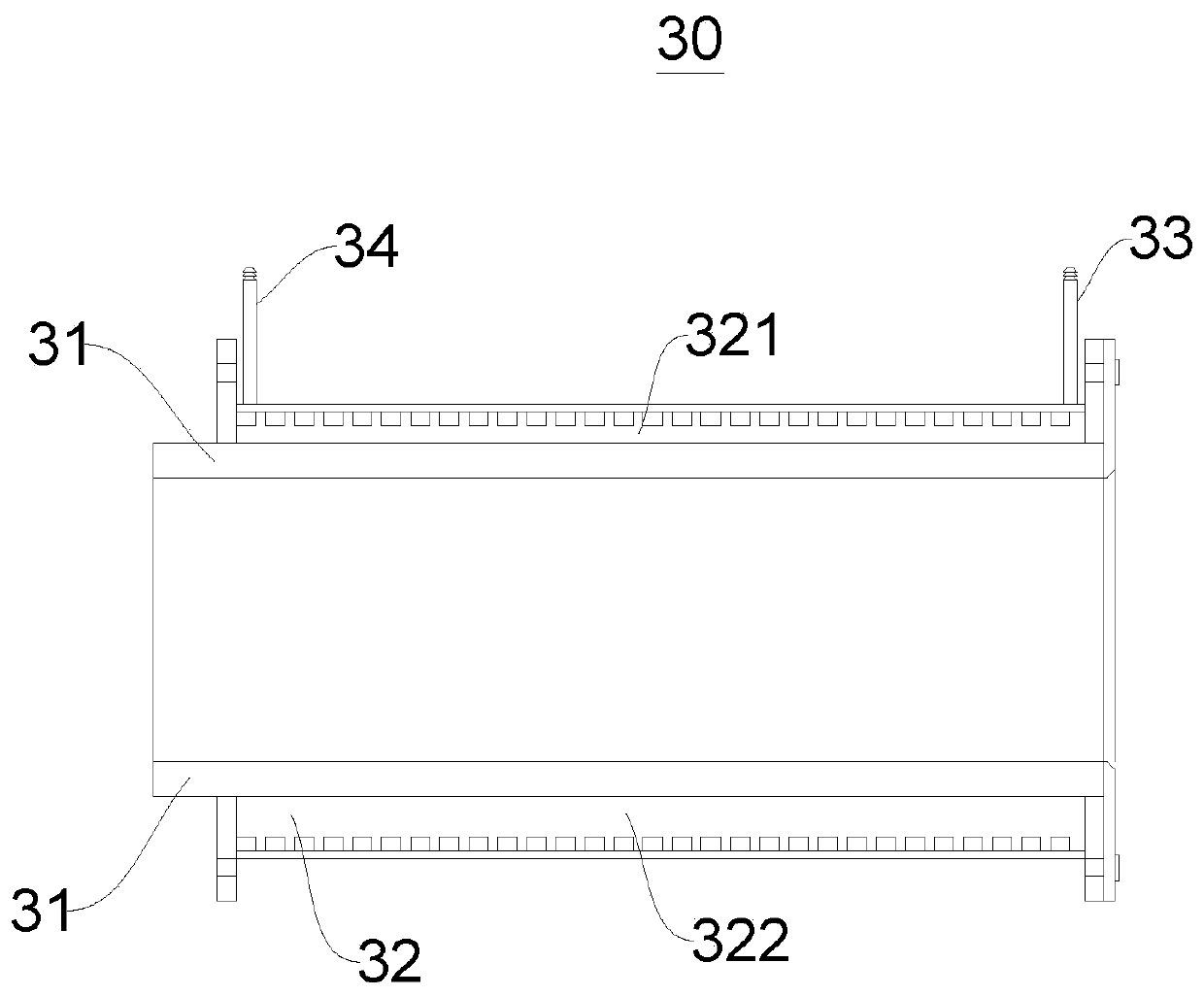

[0066] For horizontal continuous casting profi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com