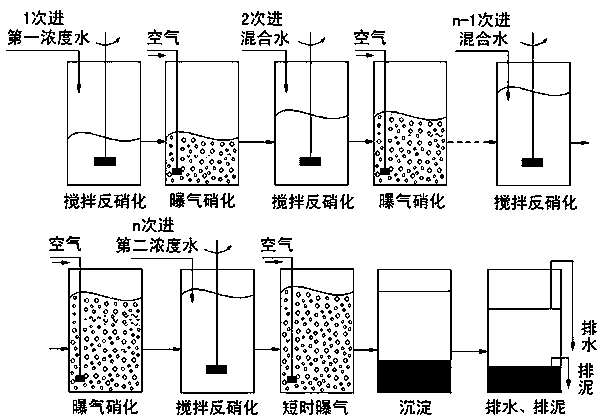

Denitrification method for corn starch wastewater of step-feeding SBR technology for partial nitrification

A segmented water inflow and cornstarch technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of complex and uneconomical operation control process, achieve the effect of simplifying operation control conditions and improving effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

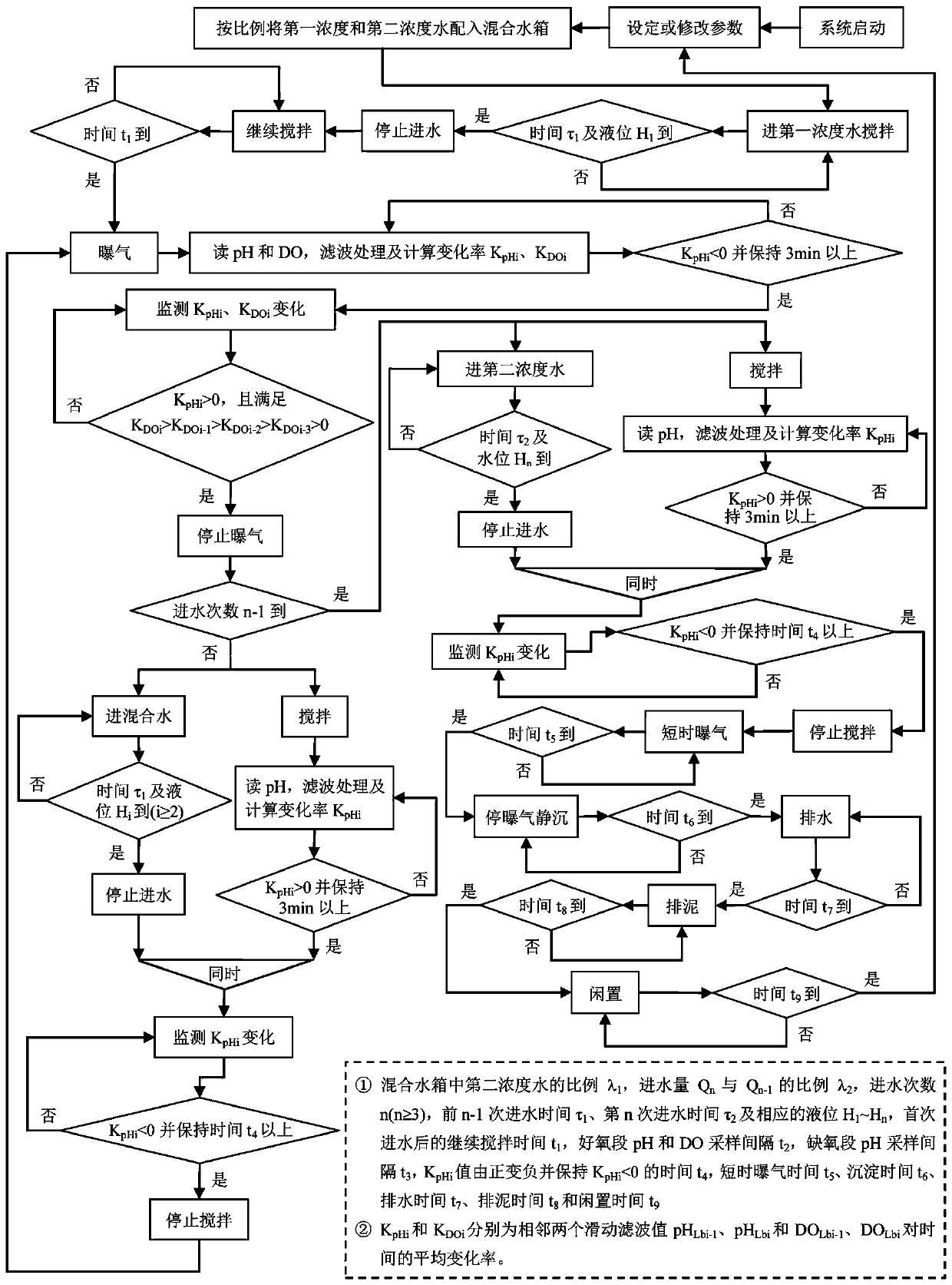

Method used

Image

Examples

specific Embodiment approach

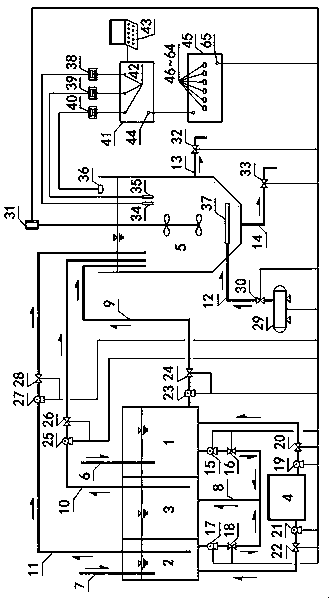

[0117] ④ According to the change of wastewater quality every day, detect C 1 、C 2 and C N value, according to the test result, the formula (1) described in the previous technical solution is used to modify λ 1 value, and then according to the modified λ 1, adjust the ratio of the first concentration water and the second concentration water into the mixing water tank 3 in real time, so that the mixing water in the mixing water tank 3 has a stable C / N ratio to meet the needs of denitrification. The specific implementation is as follows:

[0118] See attached figure 2 , the detected water quality parameter C 1 、C 2 and C N The value is input to the data processor 41 through the parameter setting and the display terminal 43, and the λ is calculated by the formula (1) stored in the data processor 1 , and show λ on the display 1 value; the λ 1 After the value is confirmed, the first concentration water distribution pump relay 46, the first concentration water distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com