Production method of polyisobutene

A technology of polyisobutylene and a production method, which is applied in the field of chemical technology, can solve the problems of complex operation, easy blockage, complex structure, etc., and achieves the effect of simplifying the process flow, realizing industrialization, and high energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0036] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0037] In the description of the present invention, it should be noted that the terms "first", "second" and so on are only used for descriptive purposes, and do not indicate or imply relative importance.

Embodiment 1

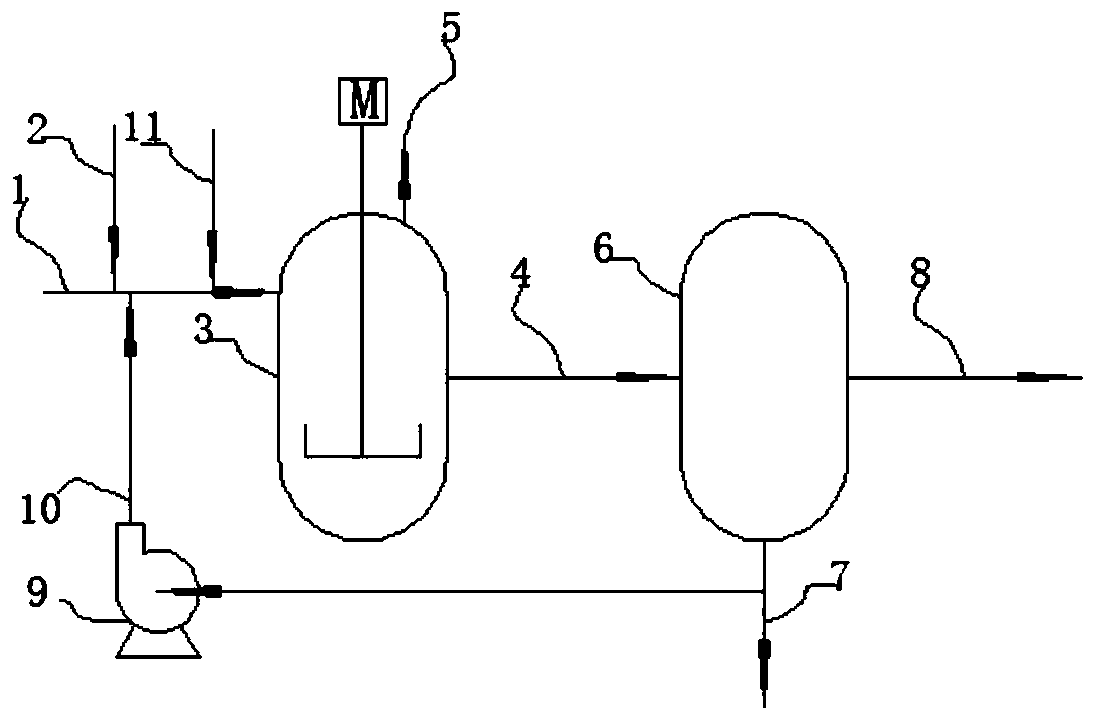

[0039] In this scheme, the production process of polyisobutylene is as follows figure 1 shown. The reaction mixture 1 obtained by polymerization (also called isobutylene polymerization reaction solution; wherein, containing polyisobutene, unreacted isobutene, solvent, catalyst, etc.) enters the first container 3 together with steam 2, supplementary process water 11, and circulating hot water 10; In the first container 3, the reaction mixture 1 is stirred and mixed with hot water, the catalyst is deactivated by the reaction with hot water, and the unreacted isobutene and solvent mixture 5 are vaporized and left from the top of the first container 3 (to separate and recover isobutene and solvent); The lower part of the first container 3 is open, and the pipeline is connected to the second container 6 , and the liquid phase flow (also called the primary separation oil phase or polyisobutylene oil phase) 4 of the preliminary separation enters the second container 6 . In the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com