A kind of nitrile rubber composition and its foaming material

A technology for nitrile-butadiene rubber and a composition is applied in the field of materials, can solve the problems of low production efficiency, insufficient cross-linking density, long vulcanization time, etc., achieves low closed cell rate, improved anti-aging and flame-retardant properties, and a preparation method. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

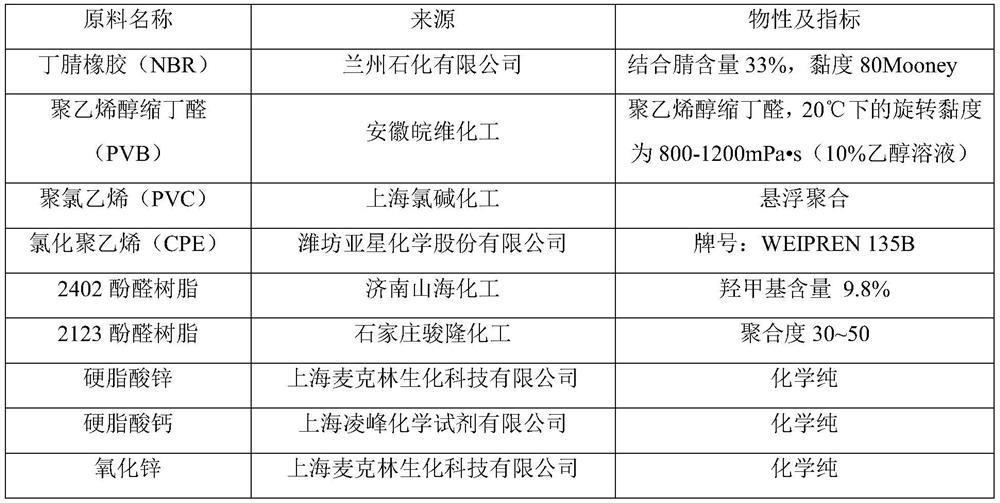

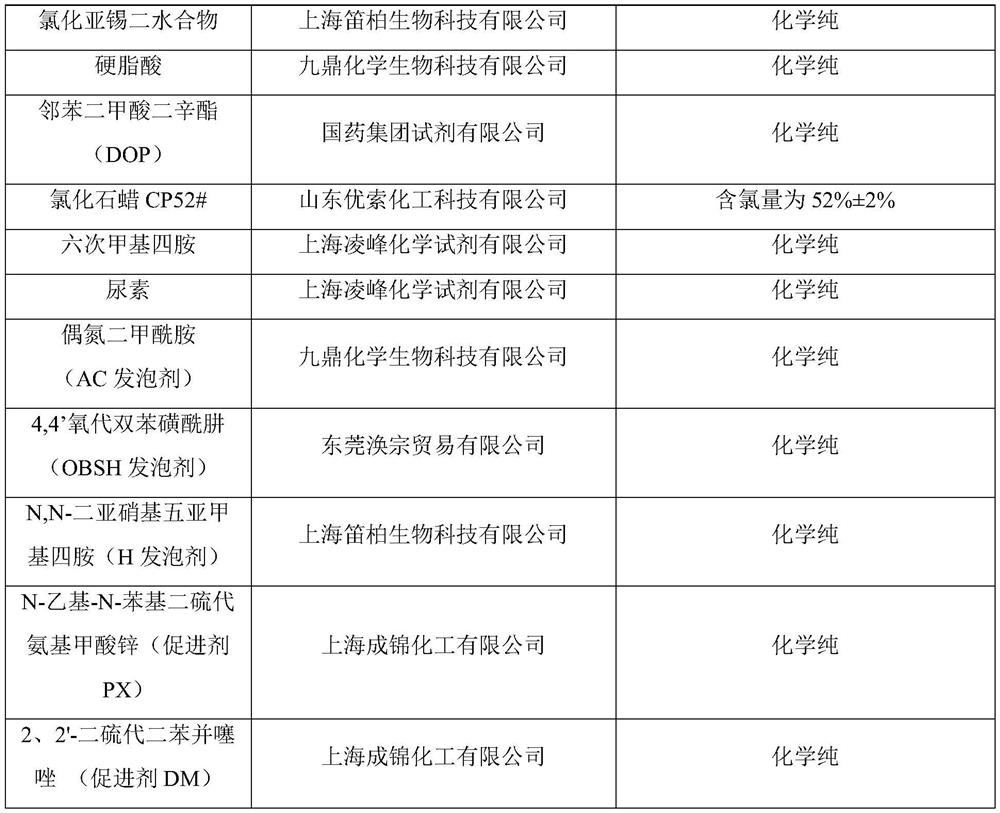

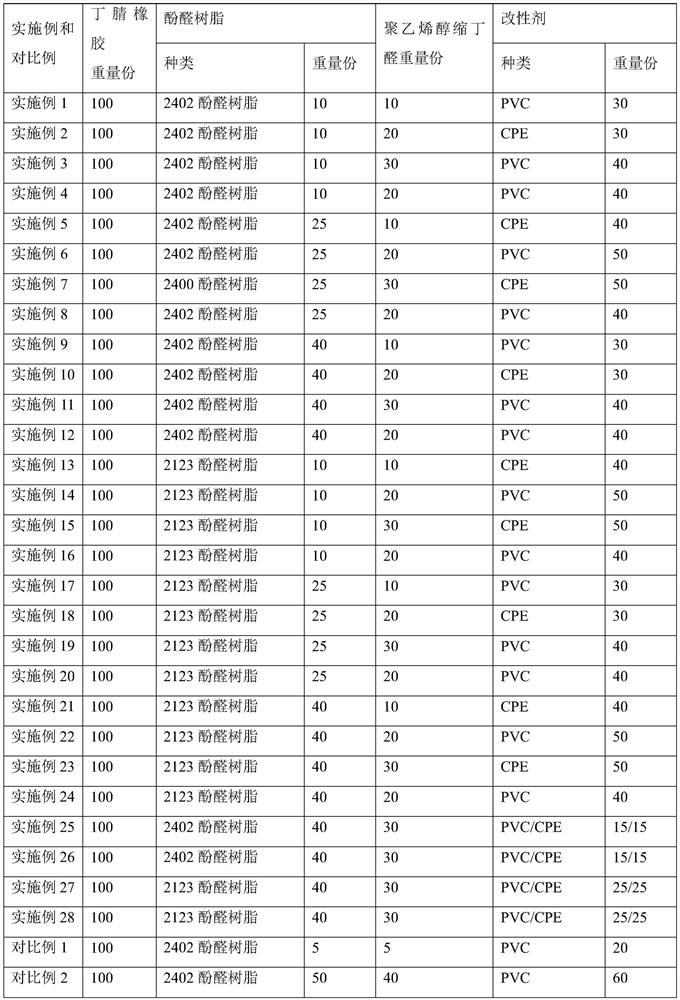

[0042] Examples and contrast:

[0043] The various raw materials of the foam material are prepared according to Table 2; the polyvinyl chloride is well mixed with the stabilizer, adding a plasticizer, placed in an oven at 80 ° C, stirred once every half an hour, allowing polyvinyl chloride The plasticizer is fully absorbed, and the polyvinyl chloride of the plasticizer is fully absorbed by the plasticizer but there is no humidity. Cut the nitrile rubber into small pieces into a small piece, the mixing temperature is 130 ° C to 100R / min, after 3 minutes, add plasticized polyvinyl chloride, anti-aging modifier, anti-aging agent, and then mix 5 min is removed to give a mixed rubber.

[0044] Further, a vulcanizing agent, a vulcanizing active agent, a vulcanization accelerator, a foaming agent is prepared according to the formulation shown in Table 3-4. On the normal temperature open mill, the accelerator, active agent, sulfurization agent is sequentially added after the mixing rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com