Corrosion-resistant alloy material for food processing machinery

A corrosion-resistant alloy, food processing technology, applied in the field of mechanical processing, can solve the problems affecting the service life of food processing machinery, the destructiveness of food processing machinery, and the corrosion of food processing machinery, so as to improve food safety, avoid corrosion, The effect of improving strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

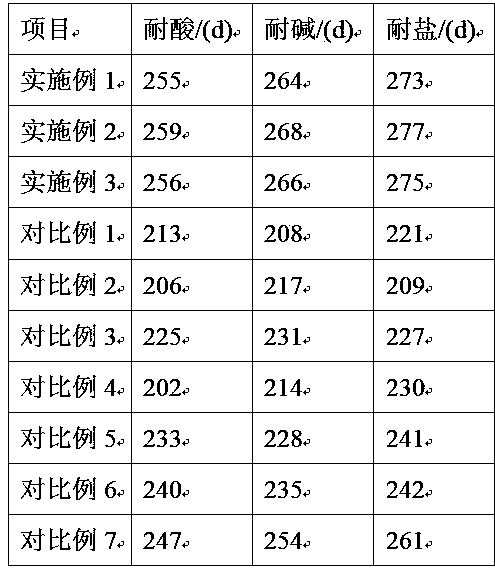

Examples

Embodiment 1

[0018] A corrosion-resistant alloy material for food processing machinery, consisting of the following components in weight percentage: 1.7% silicon, 1.7% titanium, 1.6% aluminum, 1.4% copper, 1.2% manganese, 0.7% molybdenum, 0.7% magnesium, zinc 0.6%, boron 0.5%, cobalt 0.5%, niobium 0.2%, the rest is iron and unavoidable impurities.

[0019] A method for preparing a corrosion-resistant alloy material for food processing machinery, comprising the following steps:

[0020] (1) Mix silicon, titanium and iron, heat up to 1690°C at a rate of 1.6°C / min, keep warm for 40min, remove impurities, and obtain melt A;

[0021] (2) Add molybdenum, boron and niobium into the reaction kettle, heat up to 1950°C at a rate of 2.6°C / min, hold for 20 minutes, then slowly heat to 2720°C, hold for 70 minutes to obtain melt B;

[0022] (3) Add the remaining raw materials into melt A, raise the temperature to 1940°C at a rate of 1.1°C / min, and keep it warm for 60 minutes to obtain melt C;

[0023]...

Embodiment 2

[0027] A corrosion-resistant alloy material for food processing machinery, consisting of the following components in weight percentage: 1.8% silicon, 1.8% titanium, 1.7% aluminum, 1.5% copper, 1.3% manganese, 0.8% molybdenum, 0.8% magnesium, zinc 0.7%, boron 0.6%, cobalt 0.6%, niobium 0.3%, the rest is iron and unavoidable impurities.

[0028] A method for preparing a corrosion-resistant alloy material for food processing machinery, comprising the following steps:

[0029] (1) Mix silicon, titanium and iron, heat up to 1750°C at a rate of 1.7°C / min, keep warm for 45min, remove impurities, and obtain melt A;

[0030] (2) Add molybdenum, boron and niobium into the reaction kettle, heat up to 1980°C at a rate of 2.7°C / min, hold for 25 minutes, then slowly heat to 2790°C, hold for 80 minutes to obtain melt B;

[0031] (3) Add the remaining raw materials into melt A, raise the temperature to 1985°C at a rate of 1.2°C / min, and keep it warm for 65 minutes to obtain melt C;

[0032]...

Embodiment 3

[0036] A corrosion-resistant alloy material for food processing machinery, consisting of the following components by weight percentage: 1.9% silicon, 1.9% titanium, 1.8% aluminum, 1.6% copper, 1.4% manganese, 0.9% molybdenum, 0.9% magnesium, zinc 0.8%, boron 0.7%, cobalt 0.7%, niobium 0.4%, the rest is iron and unavoidable impurities.

[0037] A method for preparing a corrosion-resistant alloy material for food processing machinery, comprising the following steps:

[0038] (1) Mix silicon, titanium and iron, heat up to 1830°C at a rate of 1.8°C / min, keep warm for 50min, remove impurities, and obtain melt A;

[0039] (2) Add molybdenum, boron and niobium into the reaction kettle, heat up to 2010°C at a rate of 2.9°C / min, hold for 30 minutes, then slowly heat to 2860°C, hold for 90 minutes to obtain melt B;

[0040] (3) Add the remaining raw materials into the melt A, raise the temperature to 2030°C at a rate of 1.3°C / min, and keep it for 70 minutes to obtain the melt C;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com