Heat changer support device and heat exchanger oil removal equipment

A support device and heat exchanger technology, which is applied in the direction of heat exchanger shell, heat exchange equipment, cleaning heat transfer device, etc., can solve the problem of complex structure, poor consistency of infrared lamp radiation temperature, and inability to meet large-scale and high-efficiency production and other problems, to achieve the effect of increasing the exposed area, heating consistency and improving the degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

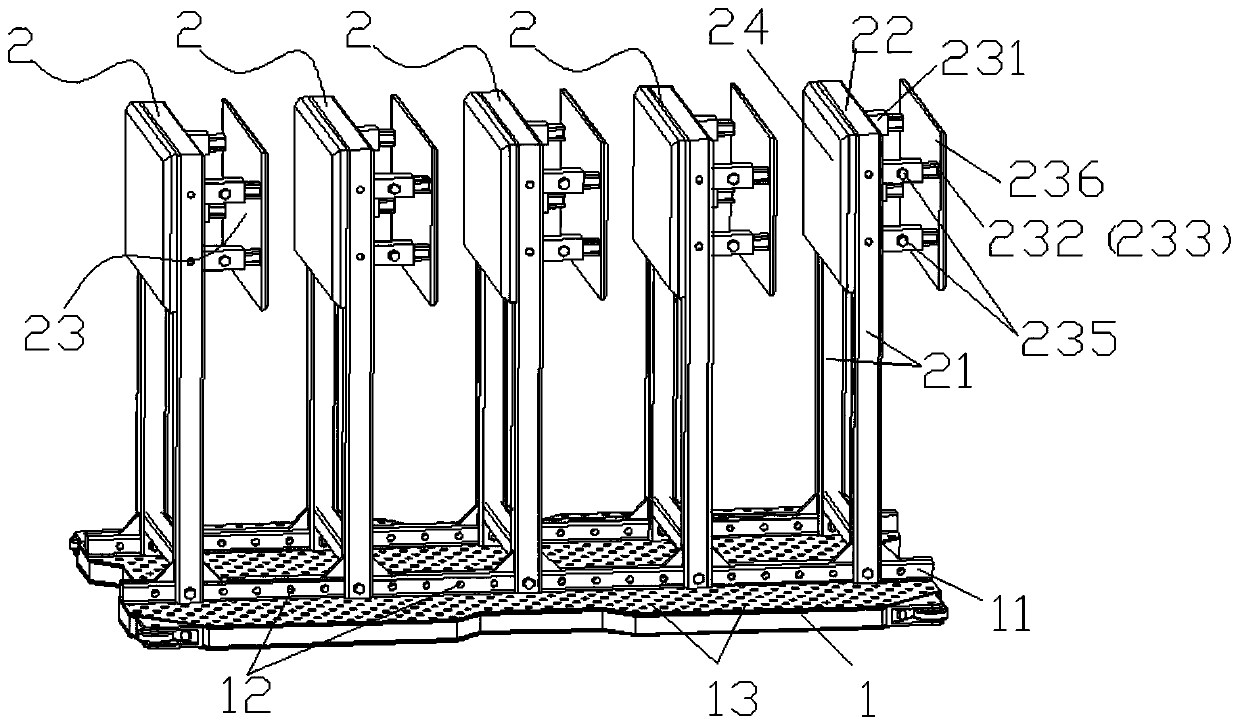

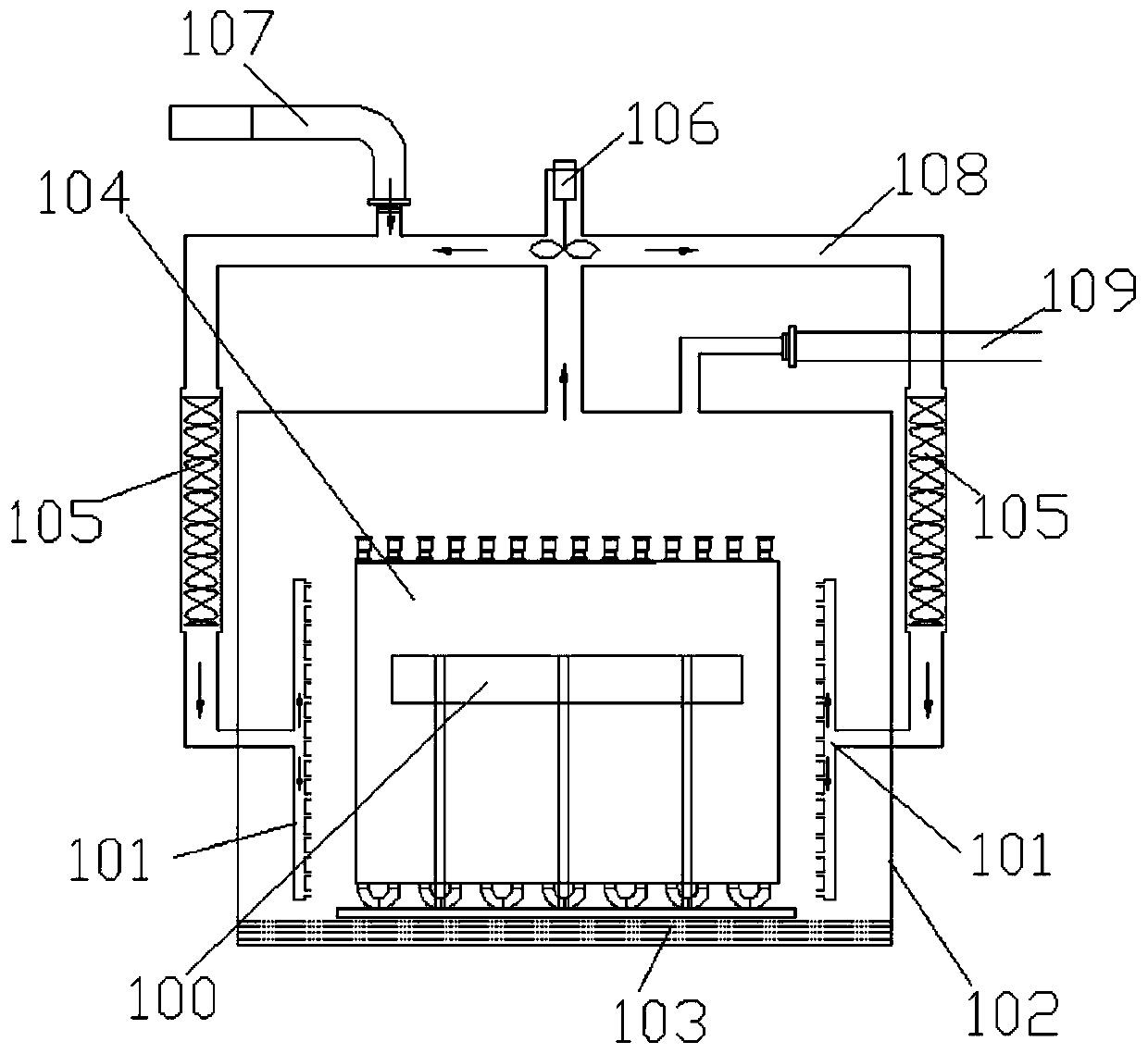

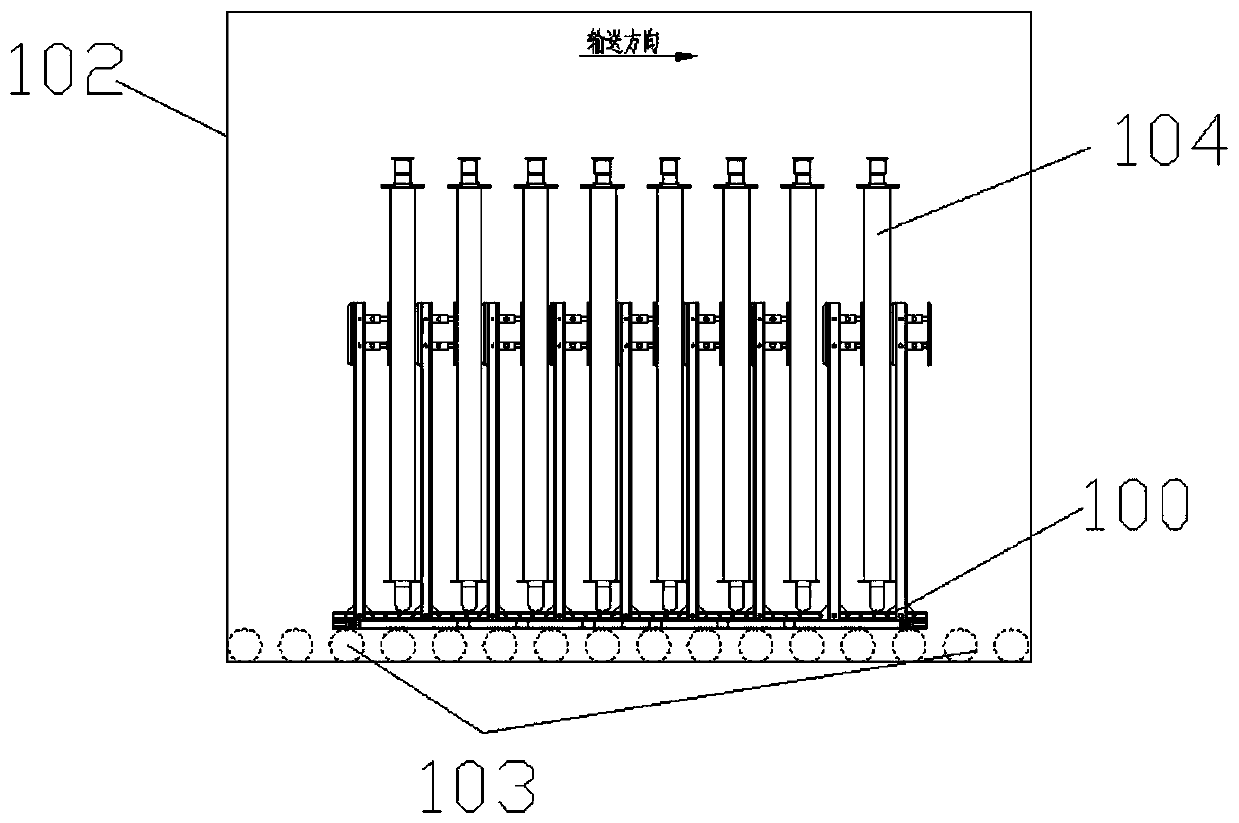

[0032] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, a support device for a heat exchanger is provided, which is used in the degreasing process of the heat exchanger, including a bottom plate 1, and at least three partition support assemblies 2 are arranged on the bottom plate 1, and each partition The supporting components 2 are arranged parallel to each other. It can be understood that the at least three separated support assemblies 2 will form at least two first gaps capable of supporting the heat exchanger 104. Placed in the first gap, on the one hand, it can increase the number of heat exchangers that enter the heating area space at a time; , to increase the exposed area of the heat exchanger 104, especially compared to the stacking treatment of multiple heat exchangers in the prior art, the current structure can be beneficial to the heat consistency of the heat exchanger and oil removal The improvement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com