A measuring device and method for measuring the three-way rigidity of different specifications of foundation supports

A foot and rigidity technology, applied in the field of CNC machine tool design, can solve the problems of long cycle, no application value, high experimental cost, etc., achieve the effects of fast three-way stiffness, real-time monitoring and acquisition, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and specific examples. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

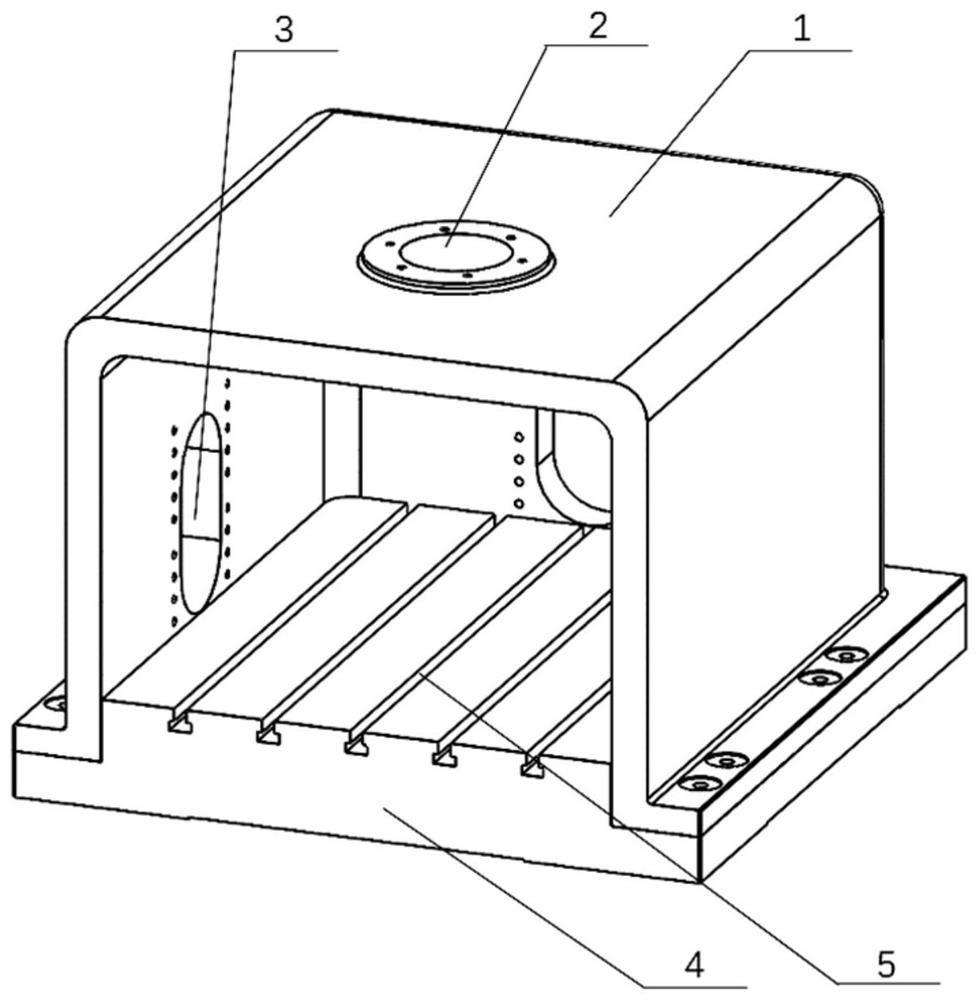

[0028] see figure 1 , The main frame structure of the measuring device is figure 1 As shown, the main frame structure is the platform and foundation of the measuring device, so the reliability of the stiffness is especially important. Therefore, the main frame is integrated with cast steel, and the actual construction of the main frame structure is considered, and the different models is disassembled. The horn is inexpensive, and the process of processing casting, transportation is installed, so that the overall structure of the main frame is designed into the upper and lower parts, and the 12 bolts are used to assemble the two parts. The final body frame is designed with a semi-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com