Positive pole material and positive pole piece for lithium ion battery and lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that cathode materials need to be improved, limited energy density improvement, poor cycle performance, etc., and achieve excellent high-voltage cycle stability and energy. The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

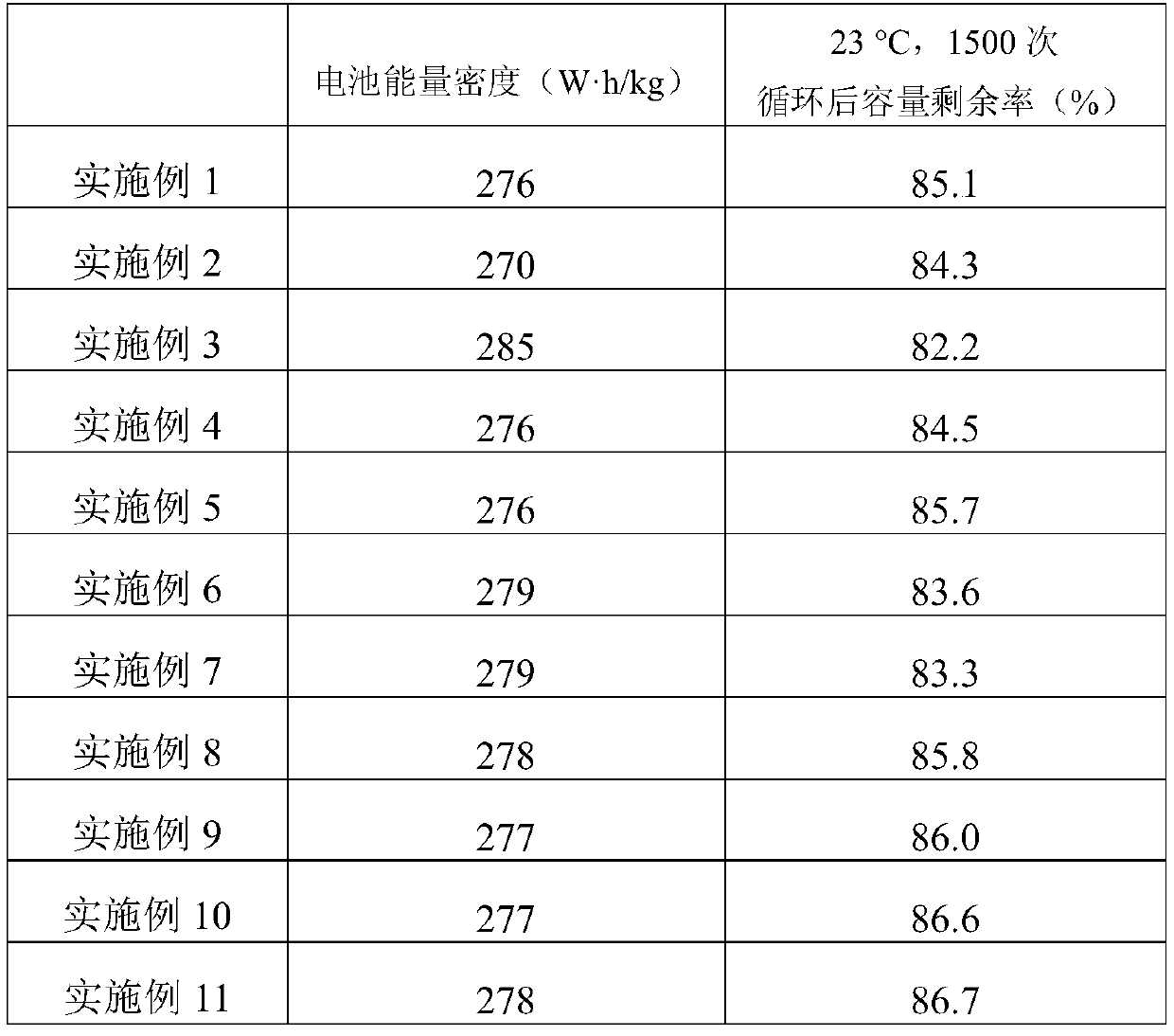

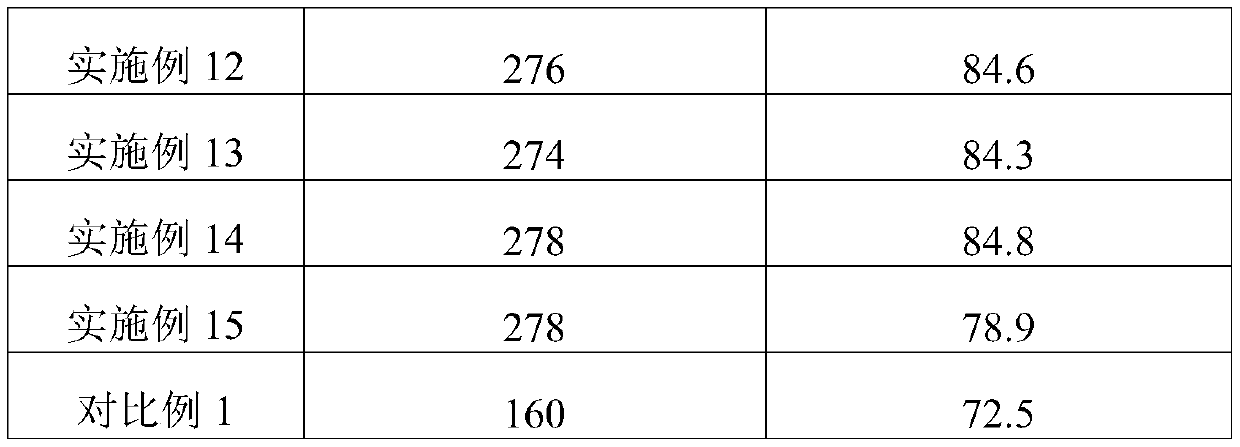

Embodiment 1

[0075] Lithium-ion power batteries are prepared according to the general method, wherein the positive electrode active material adopts LiNi 0.88 co 0.09 al 0.03 o 2 , the negative electrode active material adopts artificial graphite with a capacity ≥355mA·h / g, and 4.5wt% LiBOB, 1.5v% VC, 1.5v% PS and 2v% MEMS are added to the electrolyte. The capacity ratio (N / P ratio) of the diaphragm, the negative pole piece and the positive pole piece is the same as the general method.

Embodiment 2

[0077] Lithium-ion power batteries are prepared according to the general method, wherein the positive electrode active material adopts LiNi 0.88 co 0.09 al 0.03 o 2 The negative electrode active material adopts artificial graphite with capacity ≥355mA·h / g, and 15wt% LiBOB, 1.0v% VC, 1.5v% PS, 0.5v% MSM and 0.5v% MEMS are added to the electrolyte. The capacity ratio (N / P ratio) of the diaphragm, the negative pole piece and the positive pole piece is the same as the general method.

Embodiment 3

[0079] Lithium-ion power batteries are prepared according to the general method, wherein the positive electrode active material adopts LiNi 0.88 co 0.09 al 0.03 o 2 , the negative electrode active material adopts artificial graphite with a capacity ≥355mA·h / g, and 3wt% LiBOB, 2v% VC, 2.5v% PS and 3v% EMS are added to the electrolyte. The capacity ratio (N / P ratio) of the diaphragm, the negative pole piece and the positive pole piece is the same as the general method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com