One-pack curable type thermally conductive silicone grease composition and electronic/electrical component

A technology of thermal conductive silicone grease and composition, applied in electrical components, lubricating compositions, electrical solid devices, etc., can solve problems such as physical properties, and achieve the effect of stable heat dissipation performance and high heat dissipation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

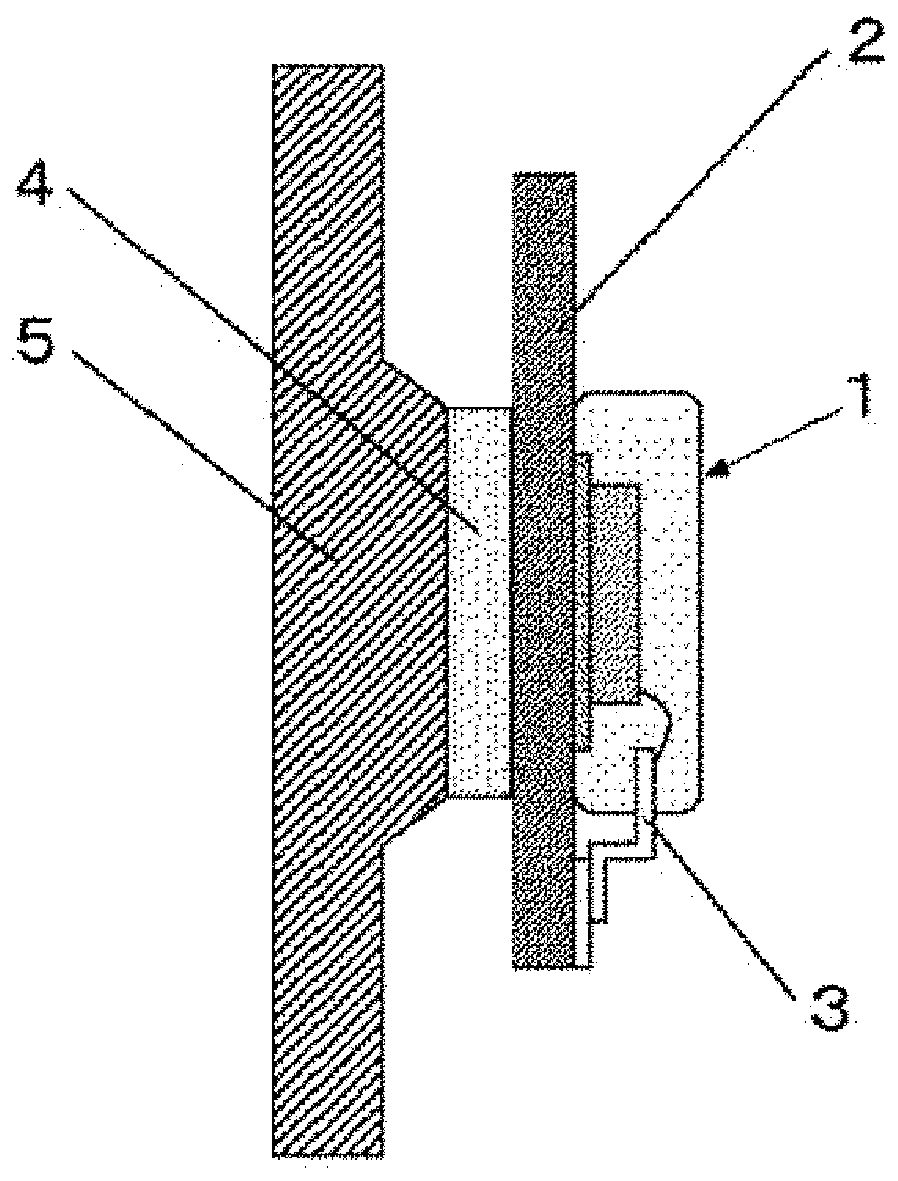

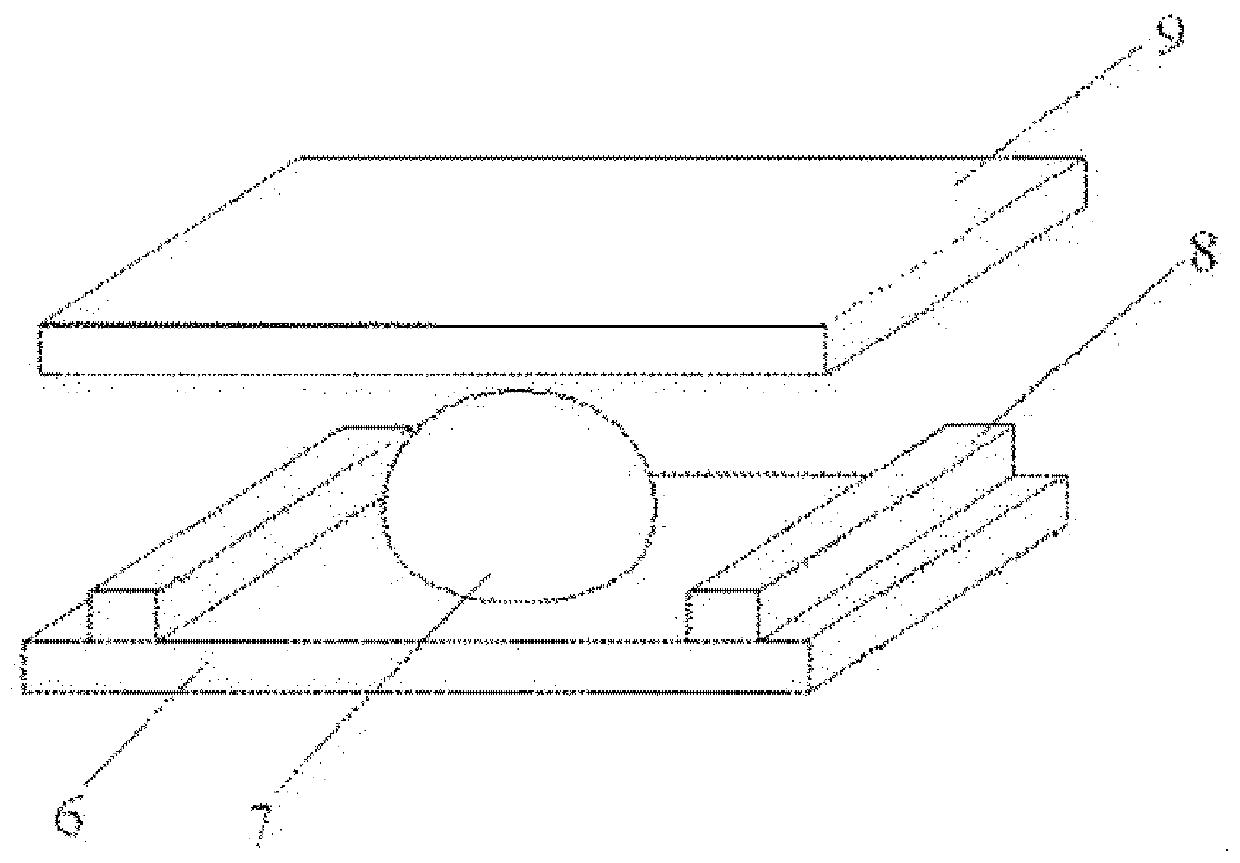

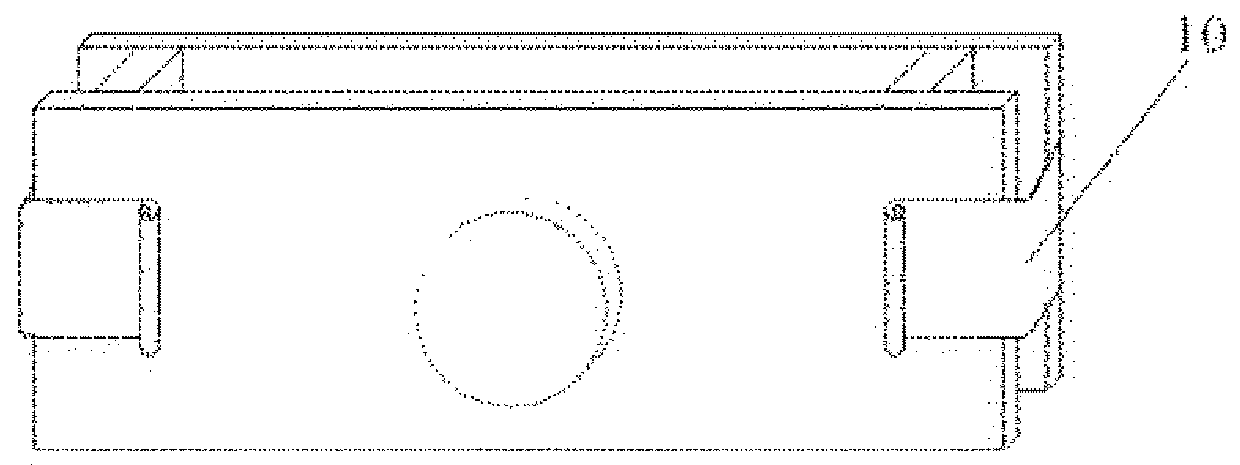

Image

Examples

Embodiment 1 to 6

[0196] [Examples 1 to 6], [Reference Examples 4, 5]

[0197]Using the method described above, components (A) to (E) and other components were mixed together in the blending amounts shown in Table 1 below to prepare a single-fluid curable thermally conductive silicone grease composition. Note that Si-H / Si-Vi (count ratio) in Table 1 is the ratio of the total number of SiH groups in the (B) component to the total number of alkenyl groups in the (A) component. After mixing (A), (C), (F), (G), (I) in a Ross mixer, heat and stir at 150° C. under vacuum for 1 hour. The mixture was then cooled to 25°C and returned to atmospheric pressure. Then, (B) and (E) were added, and after fixing, the (D) component was finally added, and the materials were mixed until uniform to prepare a single-fluid curable thermally conductive silicone grease composition. The characteristics of the single-fluid curable thermal grease composition and its cured material were measured, and the results are list...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com