Material rack and copper tube vacuum annealing furnace

A material rack and material technology, which is applied in the field of material rack and copper tube vacuum annealing furnace, can solve the problems of high energy consumption, slow heating speed and energy consumption of the copper tube vacuum annealing furnace, so as to ensure the airflow passing efficiency and heating efficiency. High efficiency and the effect of reducing annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

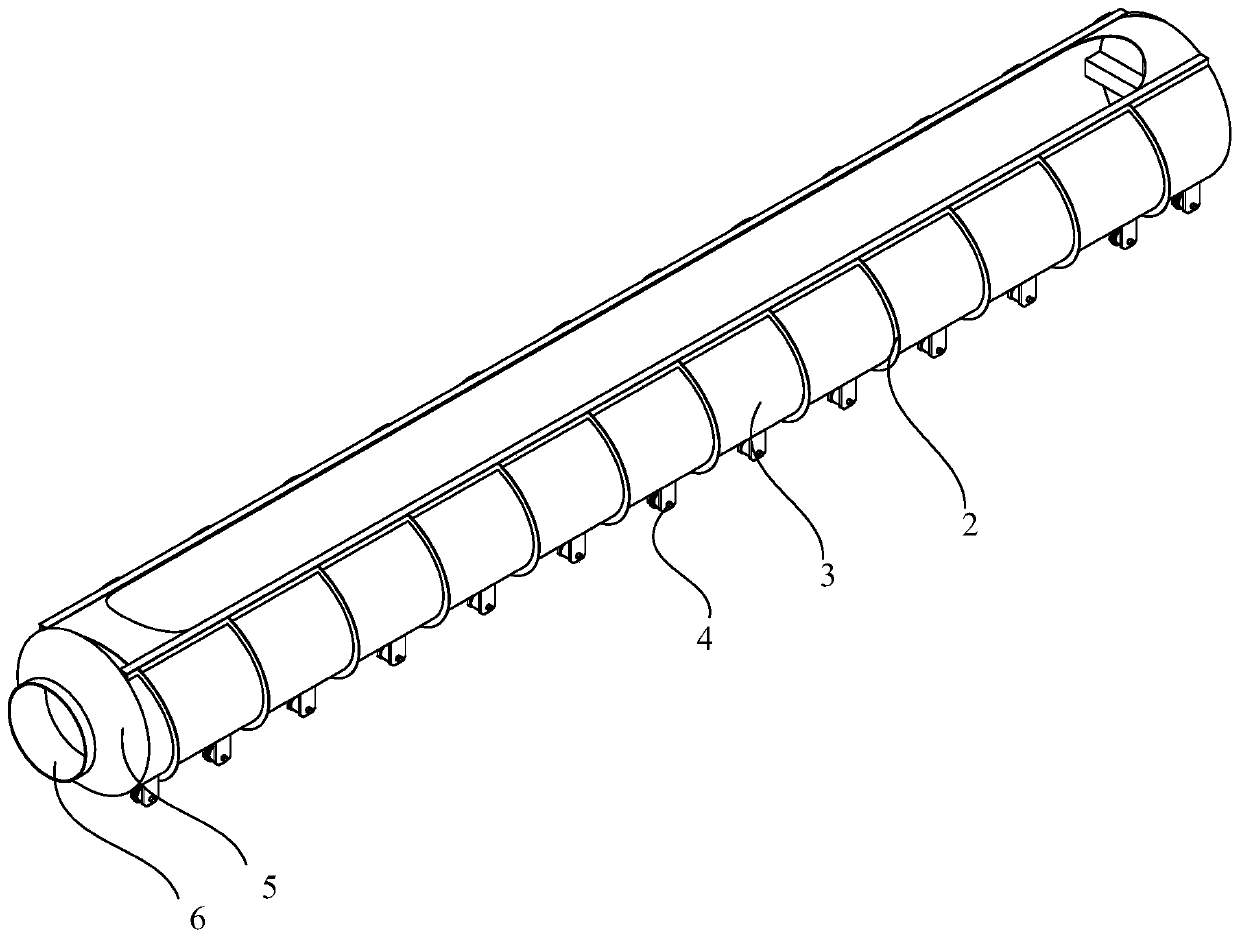

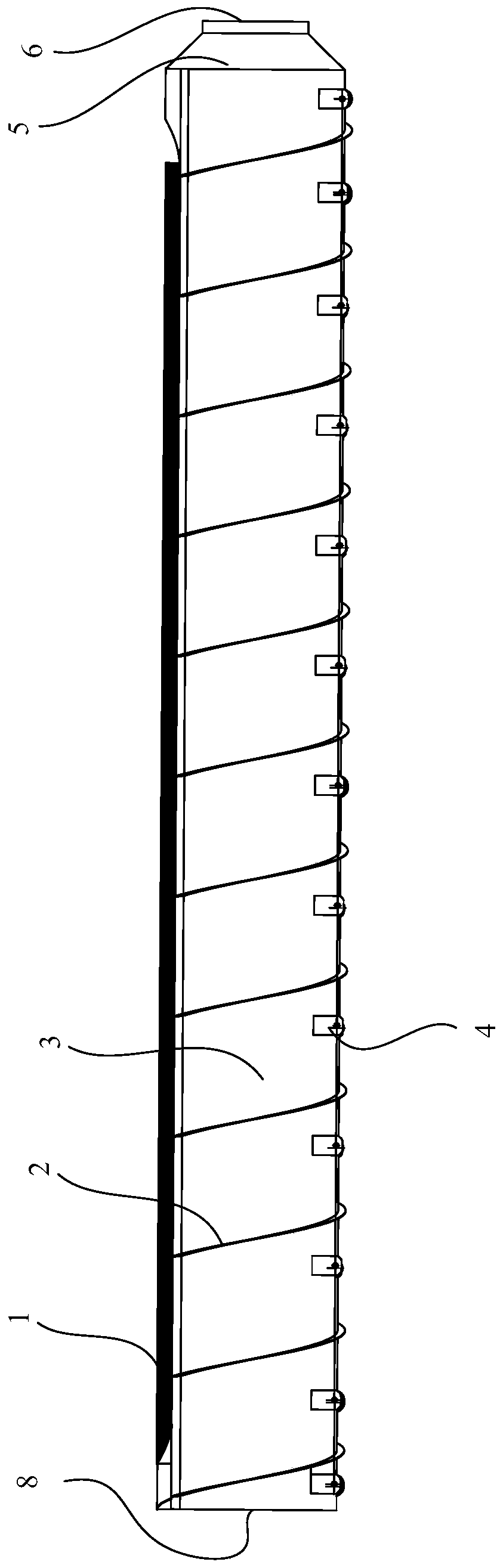

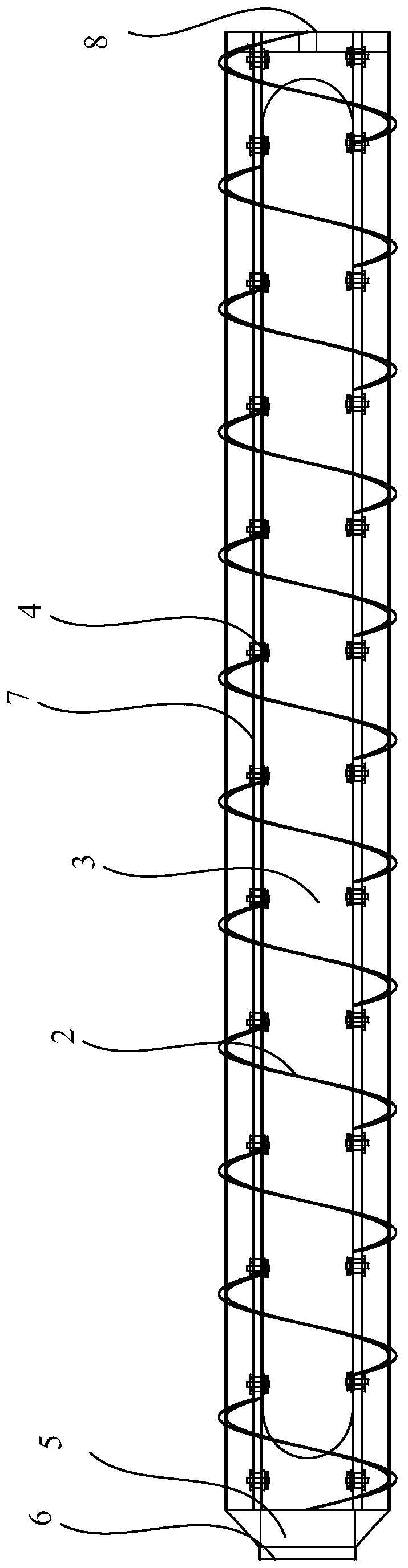

[0030] Please refer to figure 1 , the present embodiment provides a material rack, which includes a cover plate 1 , a spoiler 2 , a material rack body 3 , traveling rollers 4 , a tapered pipe 5 and a suction channel 6 .

[0031] The material rack body 3 is a hollow cylinder with openings at both ends. The openings at both ends of the material rack body 3 are respectively connected to the suction channel 6 and the air inlet channel 8. A material inlet and outlet is also provided on the peripheral wall of the material rack body 3. In this embodiment The material inlet and outlet are set above the material rack body 3, and the material inlet and outlet are connected to the inside of the material rack body 3. The cover plate 1 is arranged on the material inlet and outlet to close the material inlet and outlet. The cover plate 1 and the material The frame body 3 is detachably connected, or covered on the material inlet and outlet, so that the material frame body 3 forms a semi-clos...

Embodiment 2

[0041] This embodiment provides a copper tube vacuum annealing furnace, including a furnace, a centrifugal fan and the above-mentioned material rack, the centrifugal fan is arranged on the furnace, the material rack is arranged in the furnace, and the suction channel 6 of the material rack is arranged on On one side of the centrifugal fan, the air outlet of the centrifugal fan is docked with the suction channel 6 of the material rack.

[0042] The copper tube vacuum annealing furnace of the present embodiment is used for the annealing treatment of the copper tube. The copper tube to be annealed is placed in the material rack body 3, the cover plate 1 of the material rack is covered, and the material rack is put into the purple copper tube. In the furnace of the copper tube vacuum annealing furnace, the centrifugal fan is set on the furnace, the air outlet of the centrifugal fan is connected with the suction channel 6 of the material rack, and the walking roller 4 of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com