A wave-shaped high-rigidity anti-seismic foam concrete

A foamed concrete, wave-like technology, applied in the field of foamed concrete, can solve the problems affecting the application range of foamed concrete, low compressive strength and low elastic modulus of foamed concrete, and achieve the advantages of increasing stiffness, reducing strength reduction, and improving bonding degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

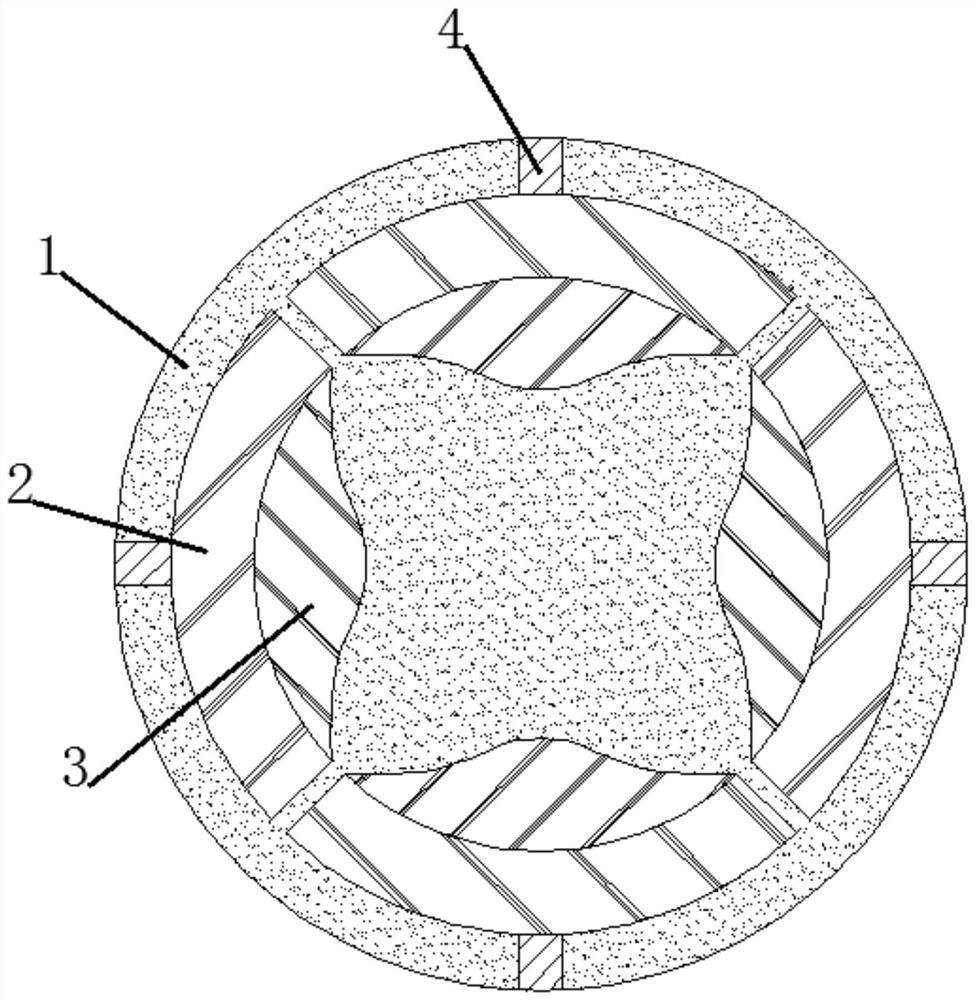

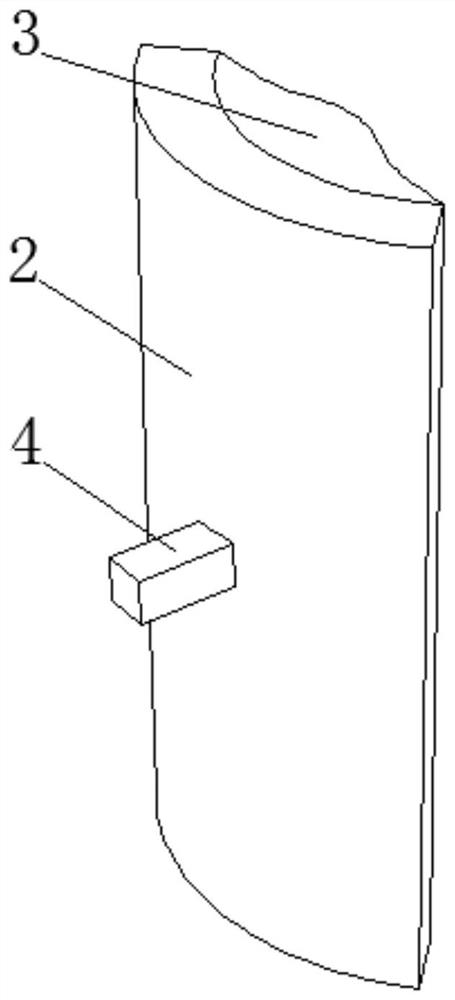

[0050] see Figure 1-2 , a wave-shaped high-rigidity anti-seismic foam concrete, including a concrete layer 1, the interior of the concrete layer 1 is wrapped with four mutually symmetrical shedding inner membranes, and the four shedding inner membranes form a micro-opening ring in the concrete layer 1. The split ring acts as a skeleton in the foam concrete, which can effectively improve the rigidity of the foam concrete. The detachable inner membrane includes the arc formwork 2, the inner formwork 3 and the magnetic positioning fulcrum 4, and the arc formwork 2 and the inner formwork 3 are fixedly connected. , and the inner template 3 is located inside the arc template 2, the magnetic positioning fulcrum 4 is fixedly connected with the outer end of the arc template 2, and the magnetic positioning fulcrum 4 is located in the middle of the arc template 2.

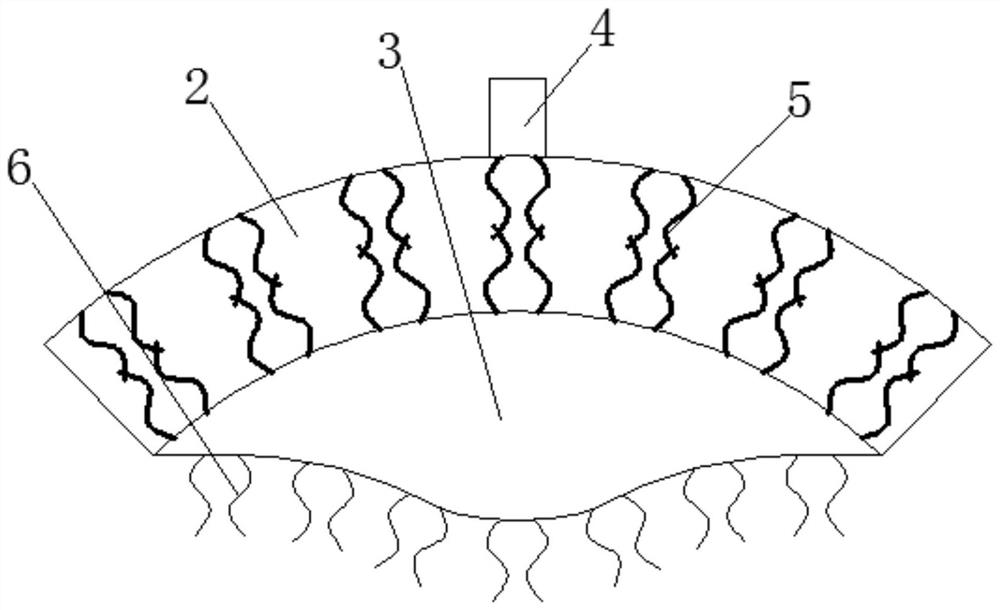

[0051] see image 3 , the interior of the curved formwork 2 is longitudinally connected with multiple groups of wave-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com