Combined single cone bit with rolling gear ring

A rolling tooth and combined technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of limiting the service life of single-cone drill bits, not being able to take away cuttings in time, and limiting the use performance of the drill bit, so as to prevent the drill bit. The effect of mud bag, lower drilling cost and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

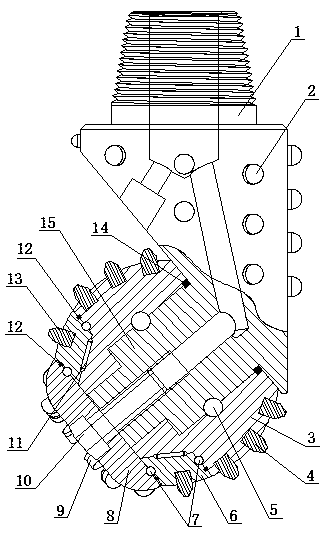

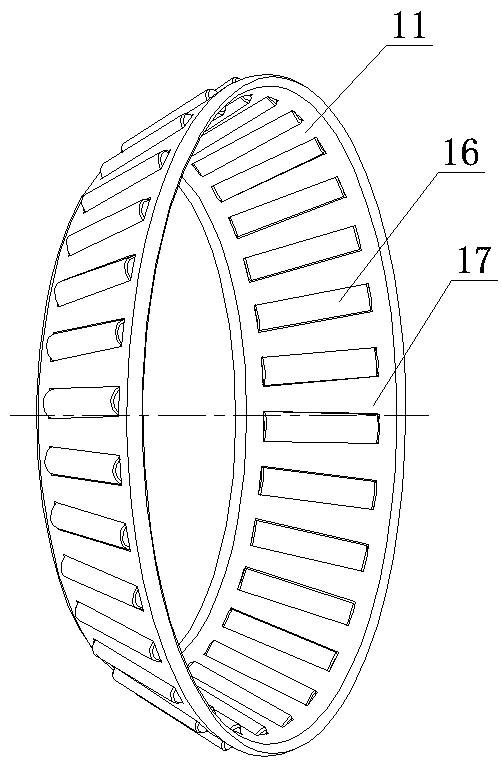

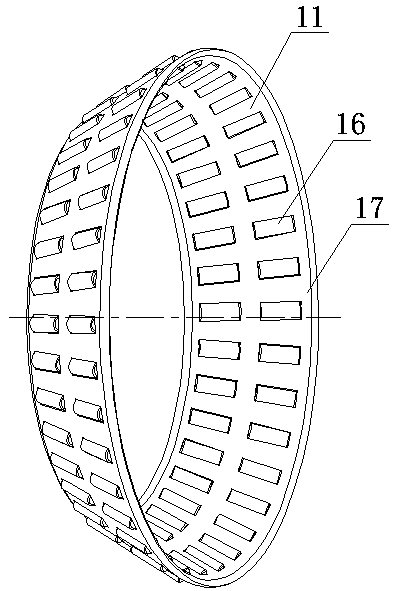

[0025] Such as Figure 1-7 As shown, a combined single-cone drill bit with a rolling ring gear includes a drill body 1, a cone 3, a cone tooth 4 and a palm journal 15, and the drill body 1 is provided with gauge teeth 2, The palm journal 15 is arranged at the lower end of the drill bit body 1, and the cone 3 is rotationally connected with the palm journal 15. The cone 3 is provided with cone teeth 4, and the cone 3 is rotationally connected with rolling teeth. Ring 6, the outer circular arc transition between the rolling ring gear 3 and the rolling ring gear 6, a needle bearing 11 is arranged between the inner ring of the rolling ring gear 6 and the rolling ring gear 3, and a needle bearing 11 is arranged between the rolling ring gear 6 and the rolling ring gear 3 There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com