Separated type aluminum plastic lamp holder

A split-type, aluminum-plastic technology, used in lighting devices, lighting device parts, light source fixing, etc., can solve problems such as damage and lamp socket cracking, and achieve the effect of extending heat dissipation performance, avoiding softening and aging, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

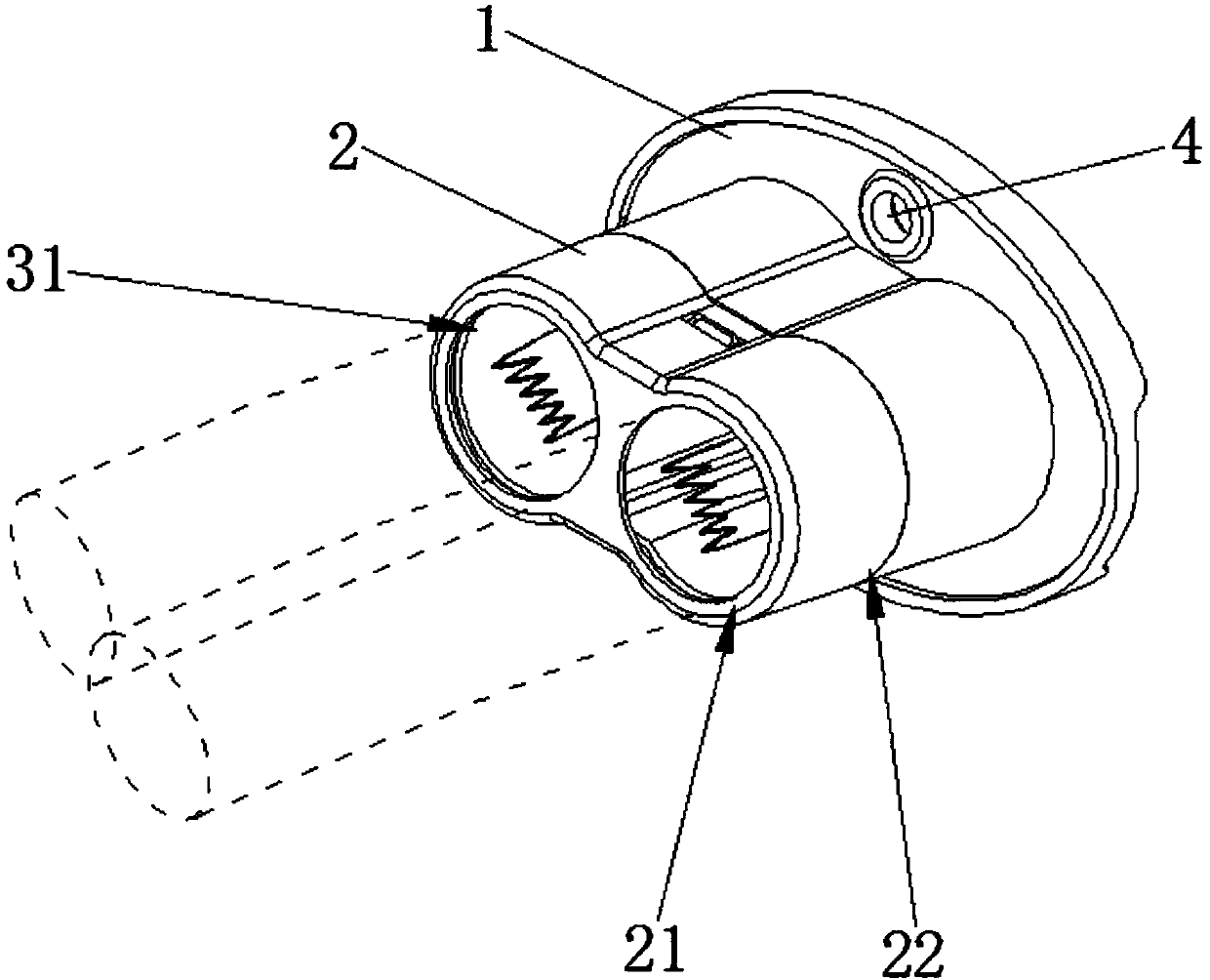

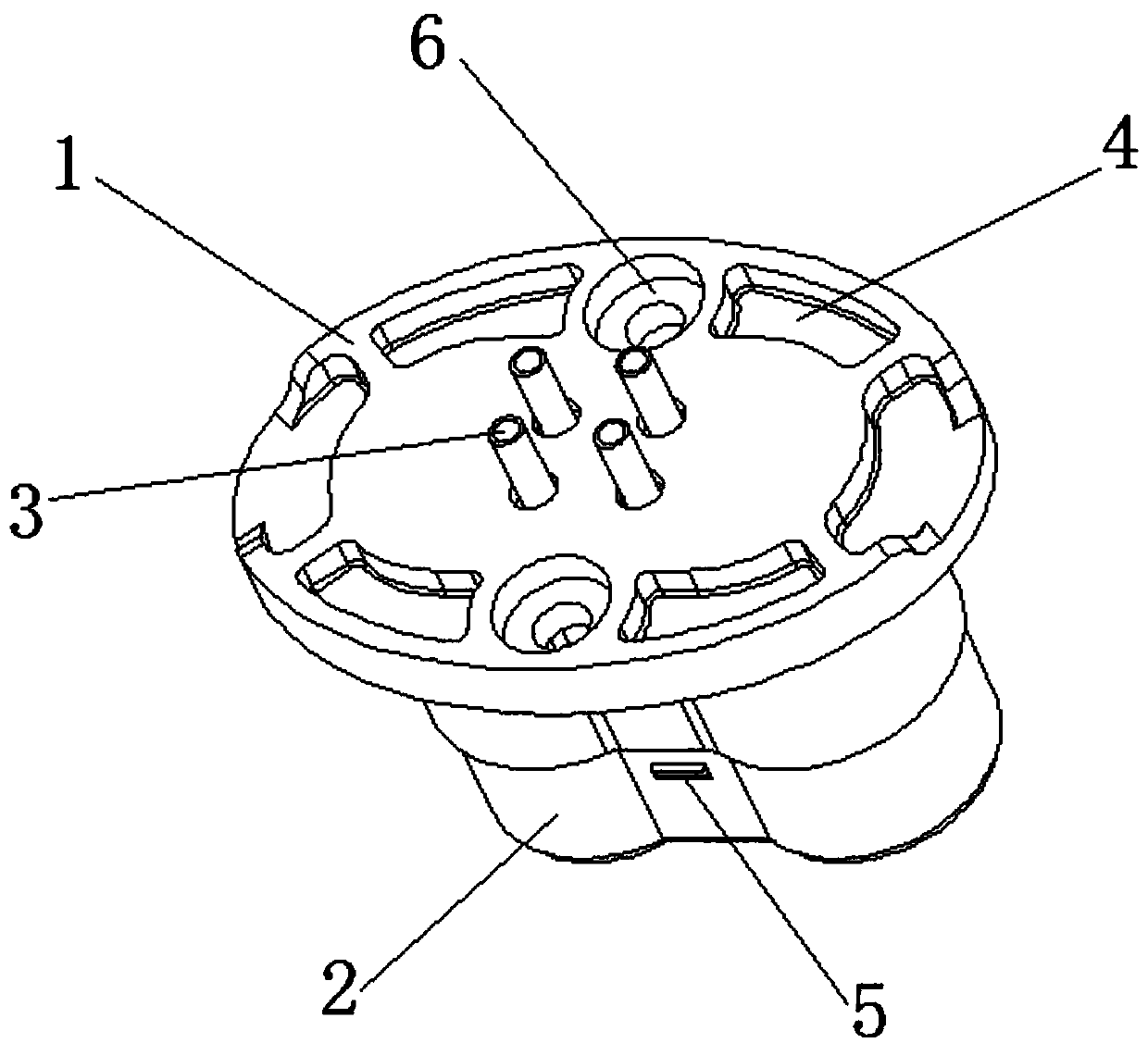

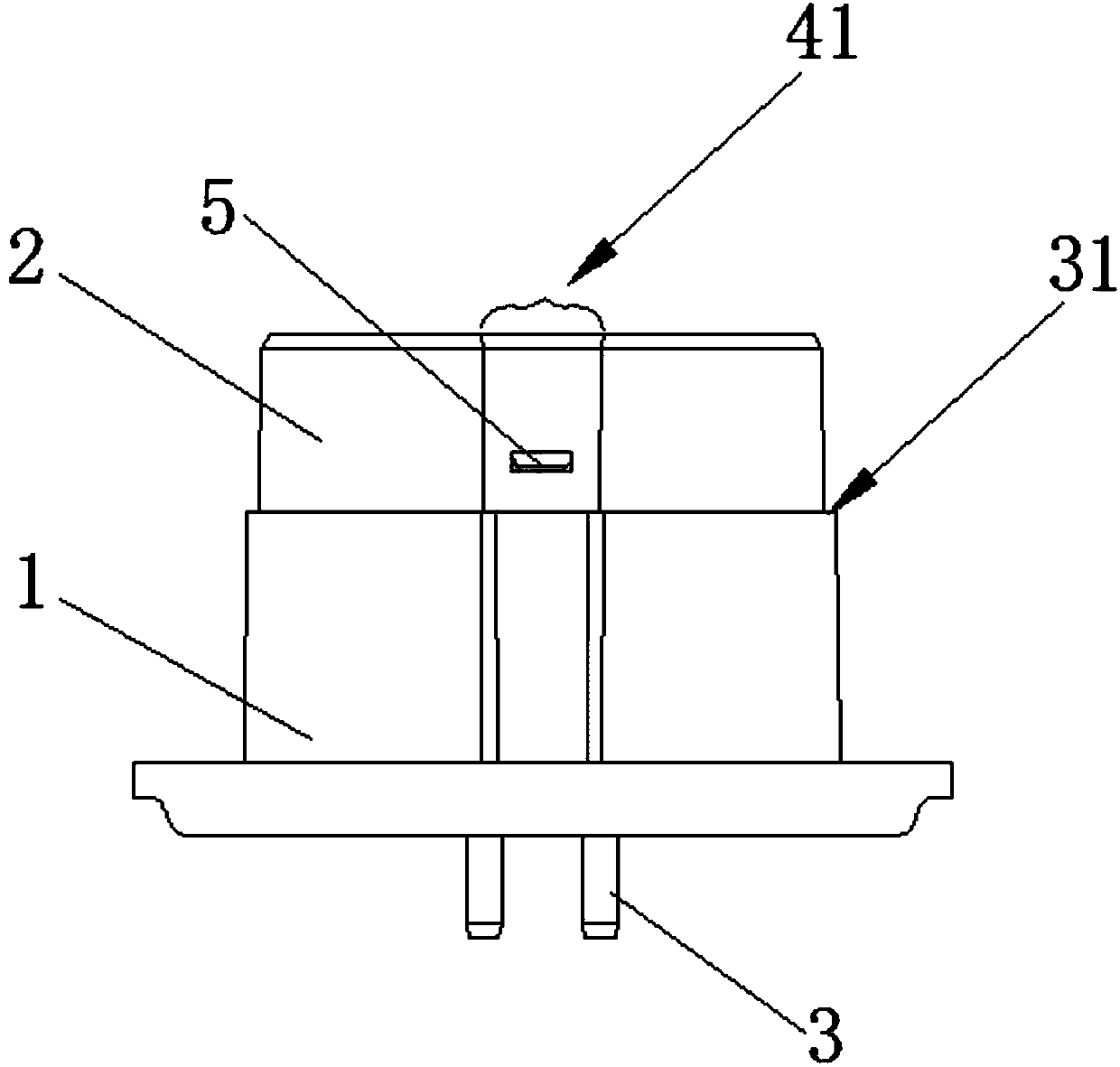

[0024] Such as figure 1 As shown in the figure, the present invention discloses a split aluminum-plastic lamp cap, which is composed of a base 1 and a tube jacket 2. The base 1 has a left-right symmetrical tube socket, and the base 1 and the tube jacket 2 Snap connection, the base 1 is made of PBT plastic, which is light in weight, which is convenient for installation and use and effectively prevents cracking; the lamp jacket 2 is made of aluminum alloy to avoid the PBT plastic from being softened at high temperature due to the heating of the tungsten wire. It is good for the heat conduction and diffusion of the tungsten wire into the air, and has good heat conduction and heat dissipation performance and prolongs the service life of the lamp tube.

[0025] In this embodiment, as Figure 1~2 As shown in the figure, the bottom of the base 1 is provided with a copper pin 3 and a groove 4. The copper pin 3 and the base 1 are fixed to each other in the mold, and the form of mutual fixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap