Method for preparing perovskite nano-crystalline film by spraying

A nanocrystal and perovskite technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem that perovskite nanocrystal films are sensitive to parameters, cannot cross the energy barrier, and cannot be quickly evaporated to dryness, etc. problems, to achieve the effect of controllable thickness, stable substrate, and reduced spraying delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

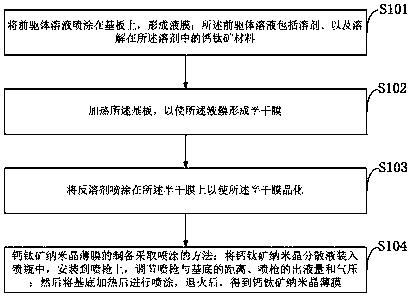

[0063] The existing spraying method does not use substrate heating in the process of preparing nanocrystalline thin films, and the droplets formed by continuous spraying cannot evaporate quickly on the surface of the substrate, forming an uneven film. Various types of perovskite nanocrystals are synthesized by the solution method, but their solution stability is worse than that of traditional types of nanocrystals. There is no report on the preparation of perovskite nanocrystal films by spraying. Therefore, it is very necessary to optimize spraying. process, so that uniform and dense perovskite nanocrystalline films with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com