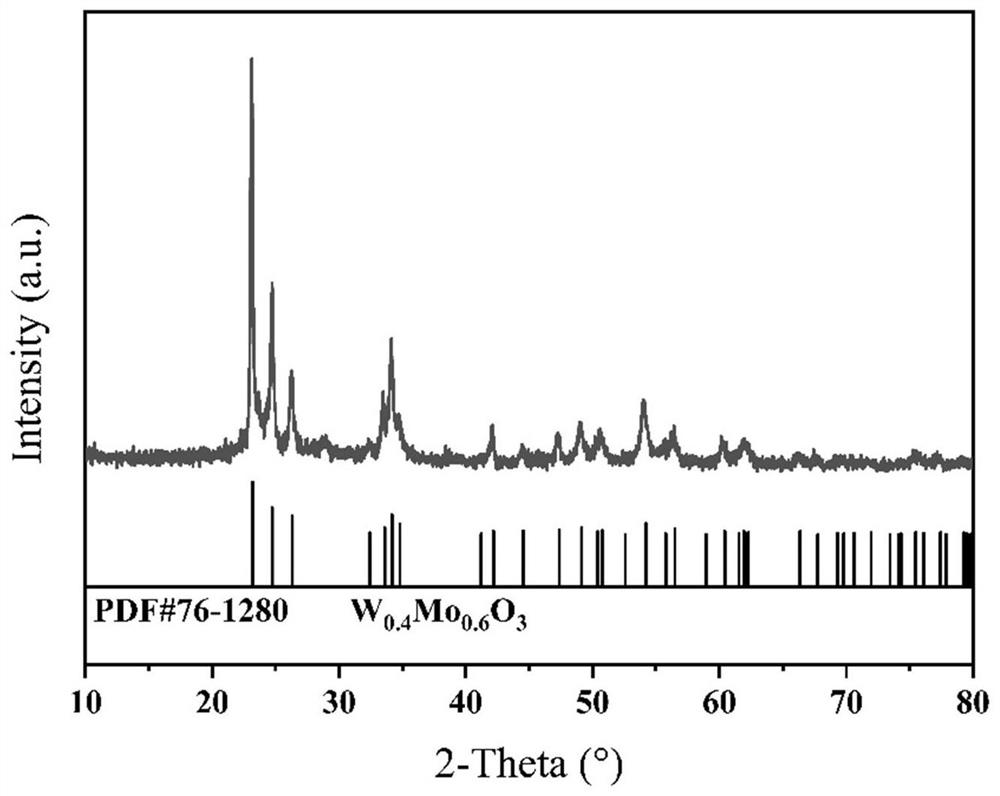

Method for preparing W0.4Mo0.6O3 in short process and application thereof

A short process, resin technology, applied in the field of micro-nano materials, can solve the problem of uncontrollable physical and chemical characteristics of mixed oxides, and achieve the effect of realizing resource recycling, reducing burden and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

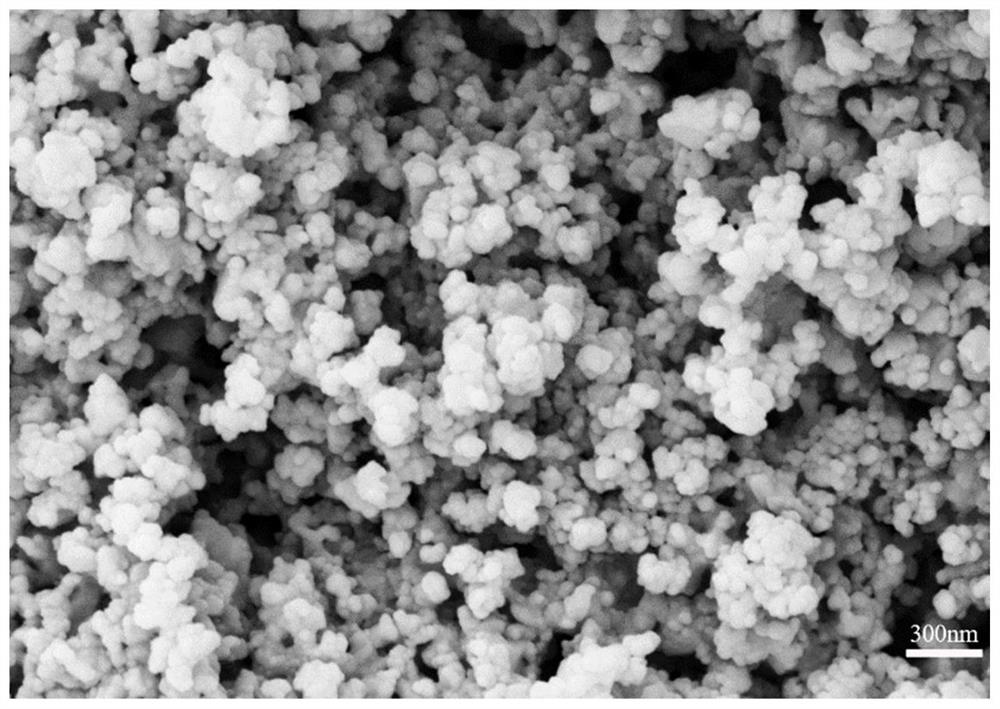

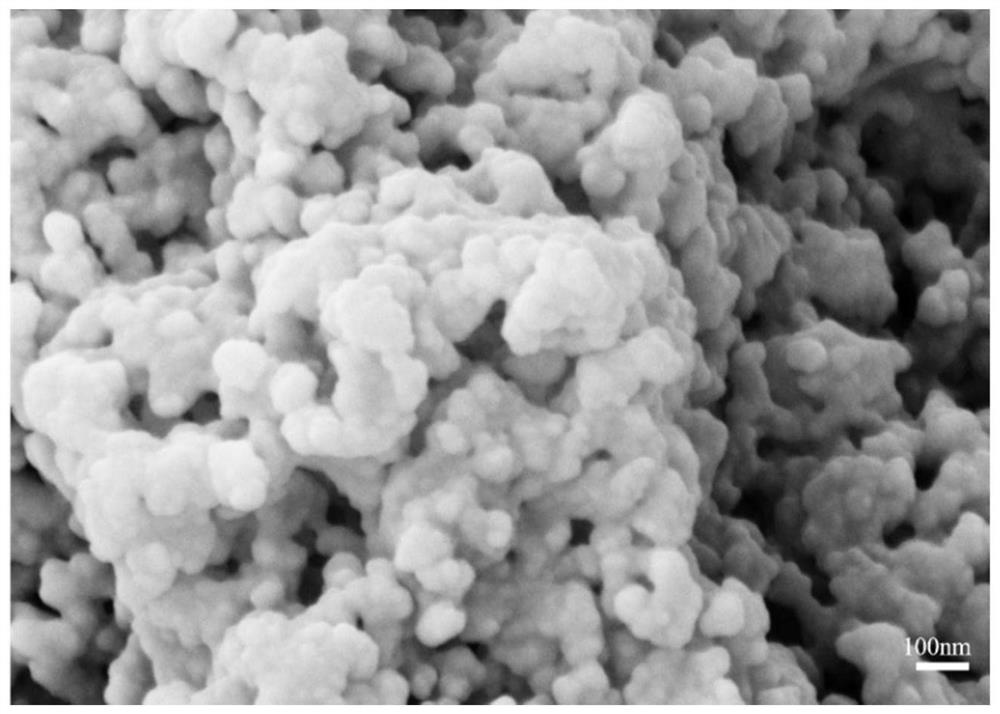

[0037] This embodiment provides a short process to prepare W 0.4 Mo 0.6 o 3 method, the specific steps are as follows:

[0038] Weigh 8g of D201 resin (D201 macroporous strongly basic styrene-based anion exchange resin, brand: McLean), and finish pretreatment by alkali washing and pickling;

[0039] Prepare a mixed solution of sodium tungstate and sodium molybdate with a concentration of 0.30mol / L; adjust the pH to 3.5 with hydrochloric acid, and let it stand for 2 hours, so that the substance to be adsorbed exists in a specific form and exists stably, so as to improve the adsorption efficiency;

[0040] Add the pretreated resin to 50ml of the above mixed solution, add magnets and stir for 4 hours;

[0041] Transfer the adsorbed resin to the reactor, add deionized water, and calcinate at 232°C for 1 hour;

[0042] Rinse the resin that has been calcined once with deionized water several times, and place it in a drying oven to dry;

[0043] Take 0.5g of the dried resin in a...

Embodiment 2

[0048] This embodiment provides a short process to prepare W 0.4 Mo 0.6 o 3 method, the specific steps are as follows:

[0049] Weigh 8g of D201 resin, and complete the pretreatment by alkali washing and acid washing;

[0050] Prepare a mixed solution of sodium tungstate and sodium molybdate with a concentration of 0.30mol / L; adjust the pH to 3.5 with hydrochloric acid, and let it stand for 2 hours, so that the substance to be adsorbed exists in a specific form and exists stably, so as to improve the adsorption efficiency;

[0051] Add the pretreated resin to 50ml of the above mixed solution, add magnets and stir for 4 hours;

[0052] Transfer the adsorbed resin to the reactor, add deionized water, and calcinate at 232°C for 1 hour;

[0053] Rinse the resin that has been calcined once with deionized water, and place it in a drying oven to dry;

[0054] Take 0.5g of the dried resin in a crucible, place it in a muffle furnace for secondary calcination, the calcination tempe...

Embodiment 3

[0058] This embodiment provides a short process to prepare W 0.4 Mo 0.6 o 3 method, the specific steps are as follows:

[0059] Weigh 8g of D201 resin, and complete the pretreatment by alkali washing and acid washing;

[0060] Prepare a mixed solution of sodium tungstate and sodium molybdate with a concentration of 0.30mol / L; adjust the pH to 3.5 with hydrochloric acid, and let it stand for 2 hours, so that the substance to be adsorbed exists in a specific form and exists stably, so as to improve the adsorption efficiency;

[0061] Add the pretreated resin to 50ml of the above mixed solution, add magnets and stir for 4 hours;

[0062] Transfer the adsorbed resin to the reactor, add deionized water, and calcinate at 232°C for 1 hour;

[0063] Rinse the resin that has been calcined once with deionized water, and place it in a drying oven to dry;

[0064] Take 0.5g of the dried resin in a crucible, place it in a muffle furnace for secondary calcination, the calcination tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com