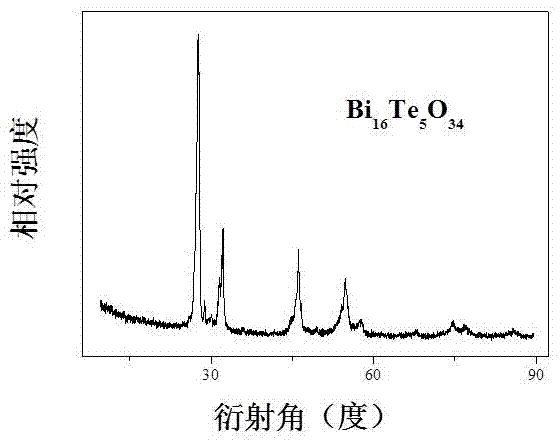

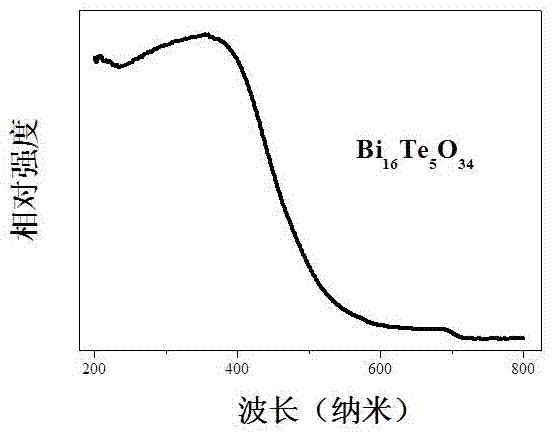

Preparing methods and applications of a visible-light-responsive bismuth oxysalt photocatalyst Bi<16>Te<5>O<34>

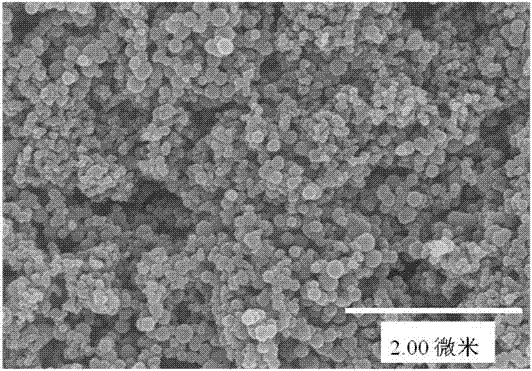

A technology of bismuth oxysalt and photocatalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of good chemical stability, good visible light response ability, and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the chemical formula Bi 16 Te 5 o 34 , respectively weigh bismuth oxide Bi 2 o 3 : 3.728 g, tellurium tetrachloride TeCl 4 : 1.347 grams, bismuth oxide is dissolved in an appropriate amount of dilute nitric acid solution, 2.882 grams of oxalic acid is weighed and added to the above solution, and continuously stirred until completely dissolved to obtain A solution; Tellurium tetrachloride is dissolved in an appropriate amount of dilute hydrochloric acid solution , Weigh 0.900 g of oxalic acid and add it to the above solution, stir continuously until it is completely dissolved to obtain solution B; slowly mix A, B and the solution, and stir at 60-80°C for 2-4 hours to obtain a viscous colloid. Stand still and dry to get a fluffy precursor. The precursor is placed in an alumina crucible, calcined in an air atmosphere in a muffle furnace, and calcined at 750° C. for 6 hours, taken out after natural cooling, and ground evenly to obtain a bismuth oxo-salt ph...

Embodiment 2

[0050] According to the chemical formula Bi 16 Te 5 o 34 , respectively weigh bismuth nitrate Bi(NO 3 ) 3 •6H 2 O: 4.851 g, tellurium dioxide TeO 2 : 0.499 grams, bismuth oxide is dissolved in an appropriate amount of dilute nitric acid solution, 2.882 grams of citric acid is weighed and added to the above solution, and stirred continuously until completely dissolved to obtain A solution; tellurium dioxide is dissolved in an appropriate amount of dilute hydrochloric acid solution , Weigh 0.901 g of citric acid and add it to the above solution, stir continuously until it is completely dissolved to obtain solution B; slowly mix A, B and the solution, and stir at 60-80°C for 2-4 hours to obtain a viscous colloid , let stand and dry to obtain a fluffy precursor. The precursor is placed in an alumina crucible, calcined in an air atmosphere in a muffle furnace, and calcined at 850° C. for 10 hours, taken out after natural cooling, and ground evenly to obtain a bismuth oxo-salt...

Embodiment 3

[0053] According to the chemical formula Bi 16 Te 5 o 34 , respectively weigh bismuth chloride BiCl 3 : 3.153 g, tellurium tetrachloride TeCl 4 : 0.842 g, bismuth oxide is dissolved in an appropriate amount of dilute nitric acid solution, 0.900 g of oxalic acid is weighed and added to the above solution, and stirred continuously until completely dissolved to obtain A solution; tellurium tetrachloride is dissolved in an appropriate amount of dilute hydrochloric acid solution , Weigh 0.281 g of oxalic acid and add it to the above solution, and stir continuously until it is completely dissolved to obtain solution B; slowly mix A, B and the solution, and stir at 60-80°C for 2-4 hours to obtain a viscous colloid. Stand still and dry to get a fluffy precursor. The precursor is placed in an alumina crucible, calcined in an air atmosphere in a muffle furnace, calcined at 780°C for 8 hours, taken out after natural cooling, and ground evenly to obtain a bismuth oxo-salt photocatalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com