Residual film recovery machine

A recycling machine and residual film technology, applied in collectors, agricultural machinery and implements, applications, etc., can solve the problems of reducing the use efficiency of agricultural machinery and tools, reducing the efficiency of mulching film picking, soil pollution in the field, etc., to achieve picking up efficiency and mulch film picking rate High, reduce labor costs, ensure the effect of picking up rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

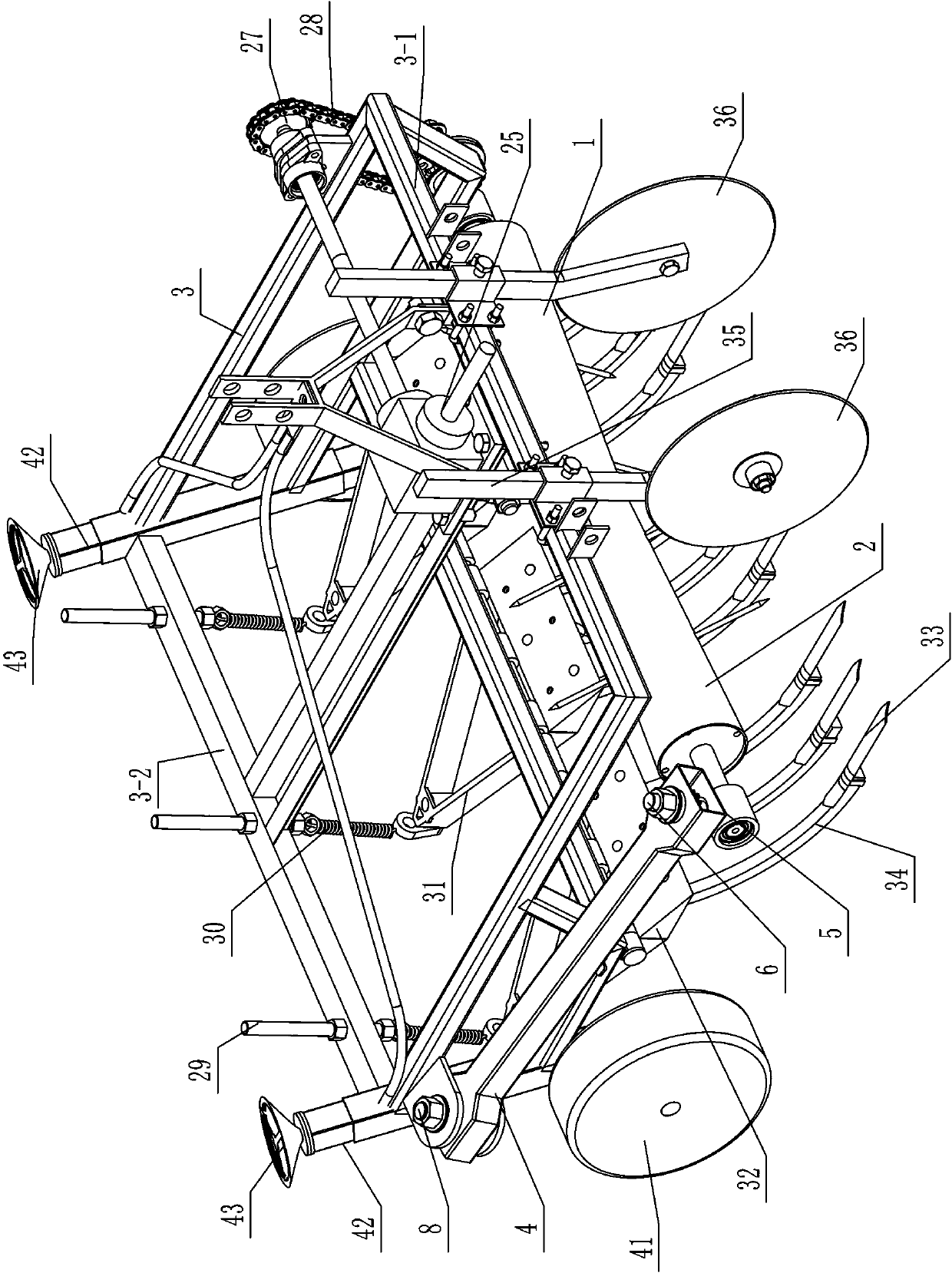

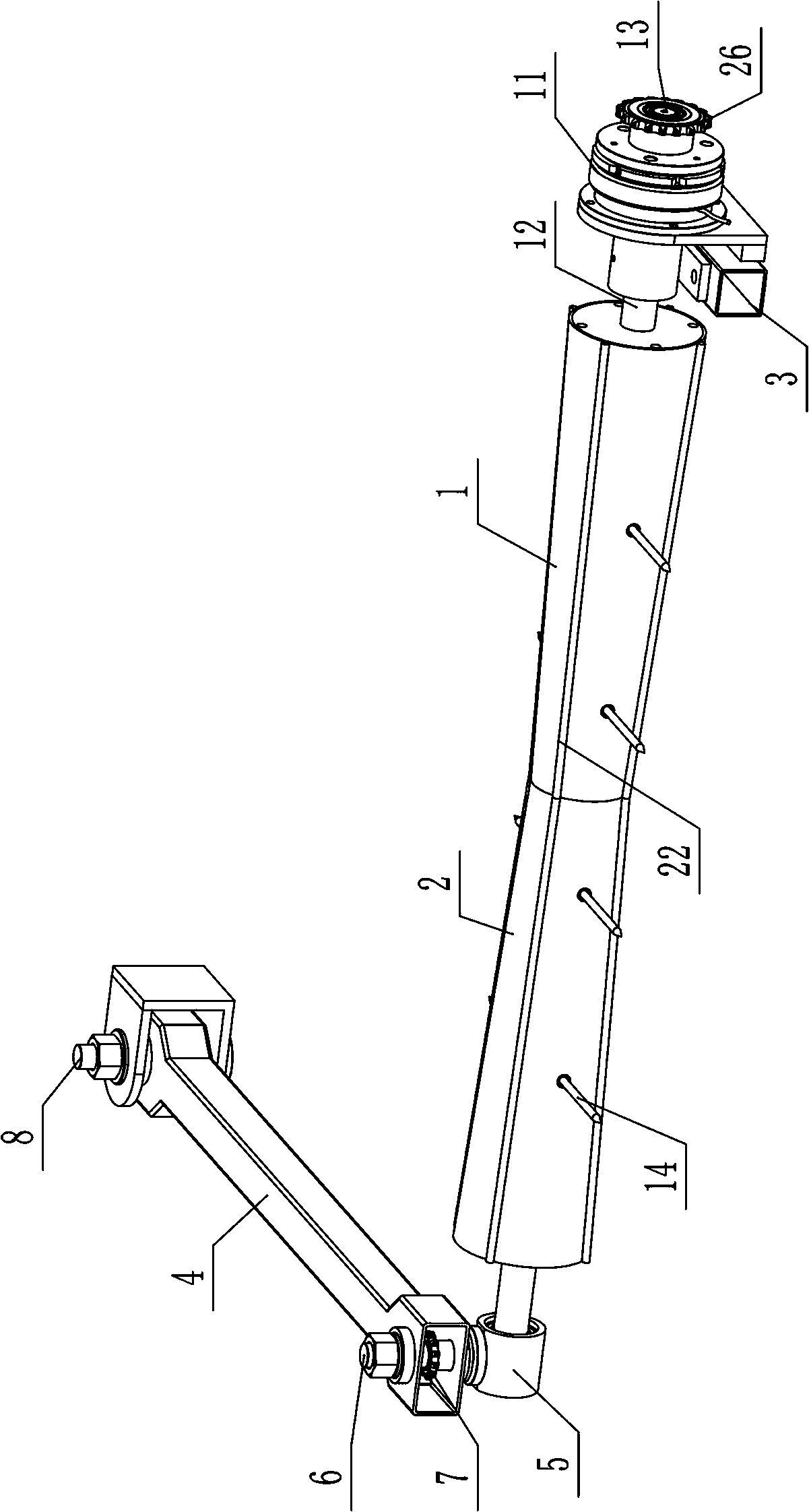

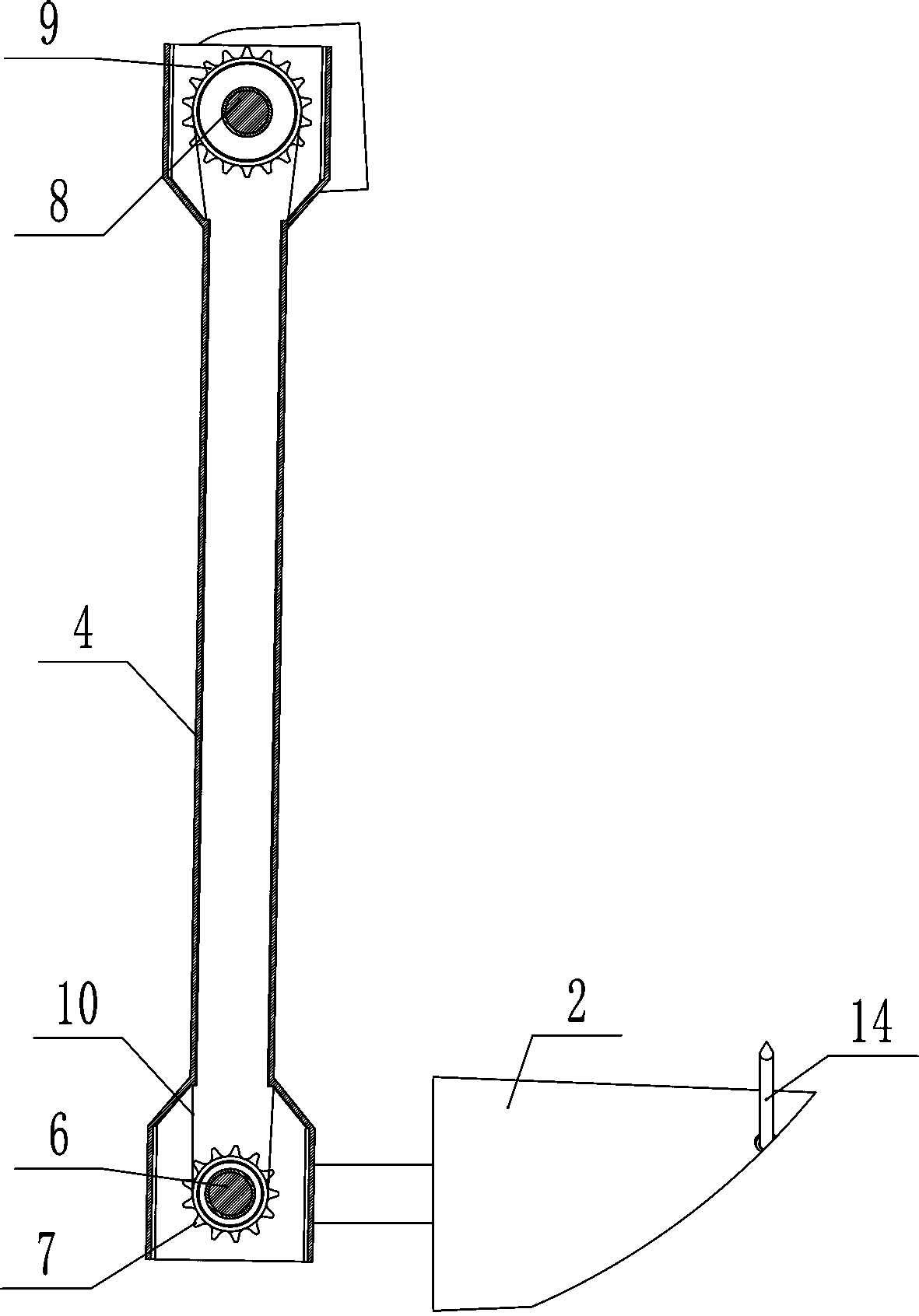

[0042] Such as Figure 1-11 The shown residual film recycling machine includes a frame 3 for fixing and installing various components and devices, and is connected with the power machine through a three-point suspension; the walking mechanism is arranged on the frame 3; the transmission box 25, It is arranged on the frame 3 for power transmission; the disc cutter device is arranged at the front end of the frame 3 for cutting stubble and / or mulch; Stirring; film rolling device, used to stir up and roll up the mulch film, connected with the transmission box 25; and linkage film unloading mechanism, used to quickly remove the mulch film on the film rolling device.

[0043] Such as figure 1 As shown, the traveling mechanism includes two travelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com