Method for reducing sulfur dioxide residues in caramel pigment

A technology of sulfur dioxide and caramel color, applied in food science and other directions, can solve the problems to be further studied, and achieve the effect of reducing the content of sulfur dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

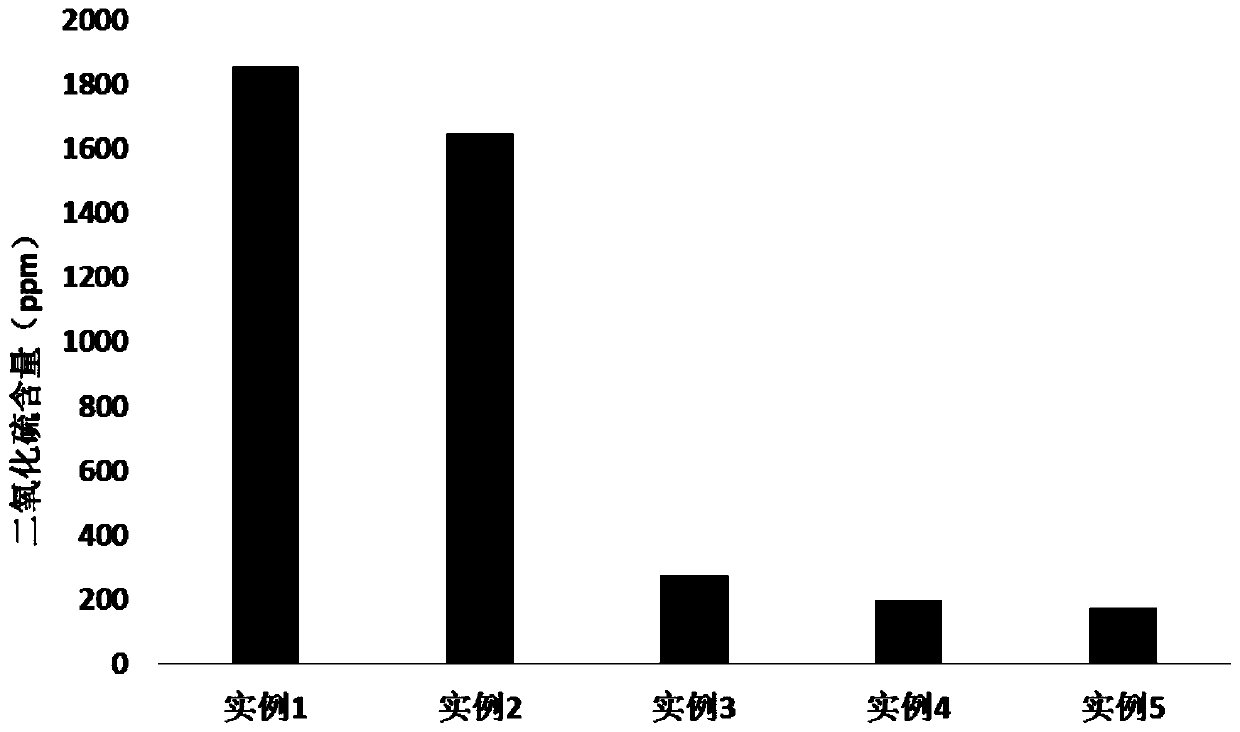

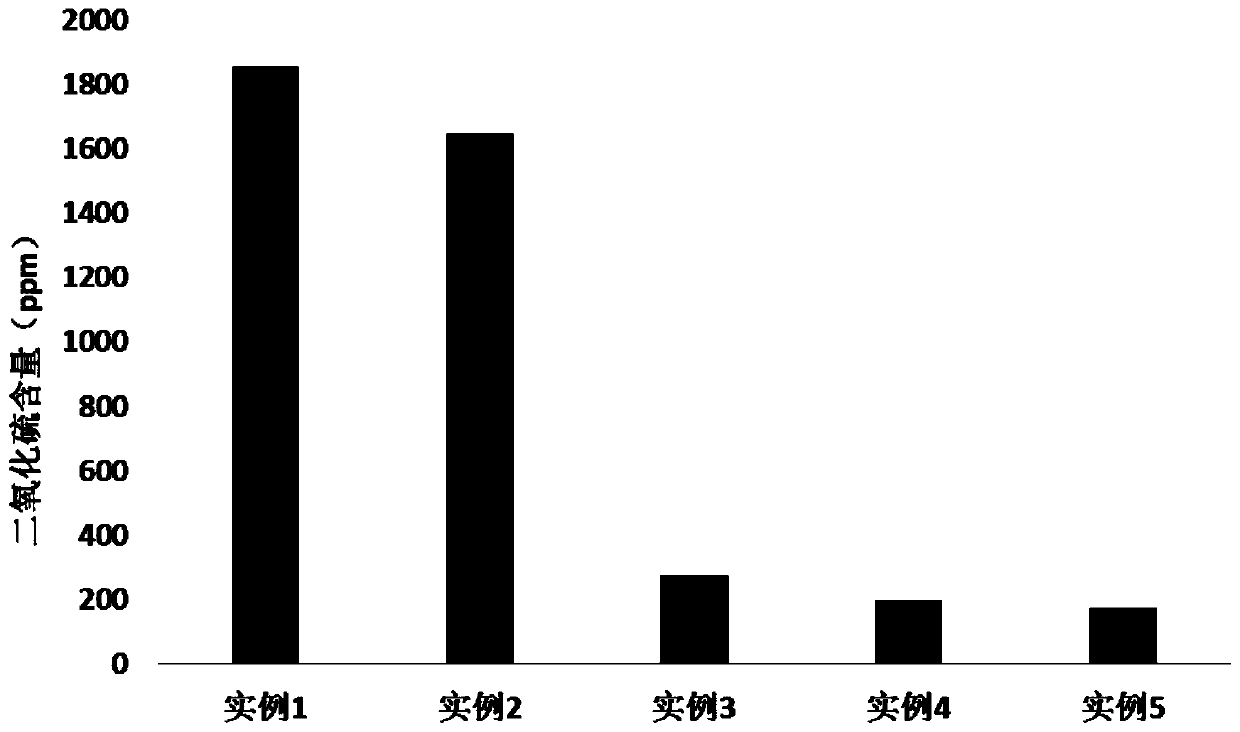

Embodiment 1

[0031] A way to reduce sulfur dioxide residues in caramel color:

[0032] Step 1): the F55 high fructose syrup with a mass solid content of 77% is concentrated to a mass solid content of 85% and then cooled for subsequent use;

[0033] Step 2): add the sodium sulfite catalyst (calculated by S) that accounts for 6% of the syrup solid mass and stir, and adjust the pH value to between 2-3 with phosphoric acid;

[0034] Step 3): heating and pressurizing reaction, the heating temperature is stabilized at 90-100 ° C, and the liquid ammonia that accounts for 2% of the syrup solid mass is passed into the feed liquid simultaneously;

[0035] Step 4): pass in all the liquid ammonia, continue to heat after stirring evenly, and control the temperature at 130-140°C;

[0036] Step 5): the heating duration is 60-80 minutes, sampling and detecting the reaction process in the reaction process, and stopping the heating before reaching the end point;

[0037] Step 6): after reaching the end po...

Embodiment 2

[0042] A way to reduce sulfur dioxide residues in caramel color:

[0043] Step 1): after concentrating the glucose syrup of 71% mass solid content to 82% mass solid content, cooling and cooling for subsequent use;

[0044] Step 2): add 8% ammonium sulfite catalyst (calculated by S) that accounts for the solid mass of the syrup and stir, and adjust the pH value to between 3-4 with phosphoric acid;

[0045] Step 3): heating and pressurizing reaction, the heating temperature is stable at 130-135 ° C,

[0046] Step 4): the heating duration is 40-60 minutes, sampling and detecting the reaction progress in the reaction process, and stopping the heating before reaching the end point;

[0047] Step 5): after reaching the end point, add water while cooling and stirring, and the diluted product is cooled to 60-80 ° C at the same time;

[0048] Step 6): Adjust pH to 3-5 with liquid sodium hydroxide, and stir well

[0049] Step 7): filter the diluted caramel color through a filter equi...

Embodiment 3

[0052] A way to reduce sulfur dioxide residues in caramel color:

[0053] Step 1): the F42 fructose syrup with a mass solid content of 65% is concentrated to a mass solid content of 80% and then cooled for subsequent use;

[0054]Step 2): add 6.5% sodium sulfite catalyst (calculated in S) that accounts for the solid mass of the syrup and stir, and adjust the pH value to between 3-4 with phosphoric acid;

[0055] Step 3): heating and pressurizing reaction, the heating temperature is stabilized at 100-105 ° C, and the liquid ammonia that accounts for 1.5% of the syrup solid mass is fed into the feed liquid simultaneously;

[0056] Step 4): pass in all the liquid ammonia, continue to heat after stirring evenly, and control the temperature at 135-140°C;

[0057] Step 5): the heating duration is 75-100 minutes, sampling and detecting the reaction progress in the reaction process, and stopping the heating before reaching the end point;

[0058] Step 6): after reaching the end poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com