A kind of far-red and near-infrared emitting fluoride fluorescent material and its preparation and application

A fluorescent material and near-infrared technology, applied in the directions of luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of low plant efficiency, lack of far-red light and near-infrared light, and inability to adjust the proportion of light, and achieve the preparation method. Simple, wide-ranging, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A far-red and near-infrared emitting fluoride fluorescent material, the chemical expression of the fluorescent material is K 3 al 0.98 f 6 : 0.02Cr, its preparation steps are as follows:

[0033] 1. Weigh the raw material KF·2H 2 O 0.03mol, AlF 3 ·3H 2 O 0.0098mol, CrF 3 0.0002mol, weigh 20% of the total weight of raw materials NH 4 F;

[0034] 2. After fully mixing the weighed raw materials, sinter at 750°C for 3 hours in an argon atmosphere to obtain a roasted product;

[0035] 3. After fully grinding the obtained roasted product into powder and passing through a 200-mesh sieve, washing with deionized water for 3 times, and drying at 80°C, the K 3 al 0.98 f 6 : 0.02Cr phosphor.

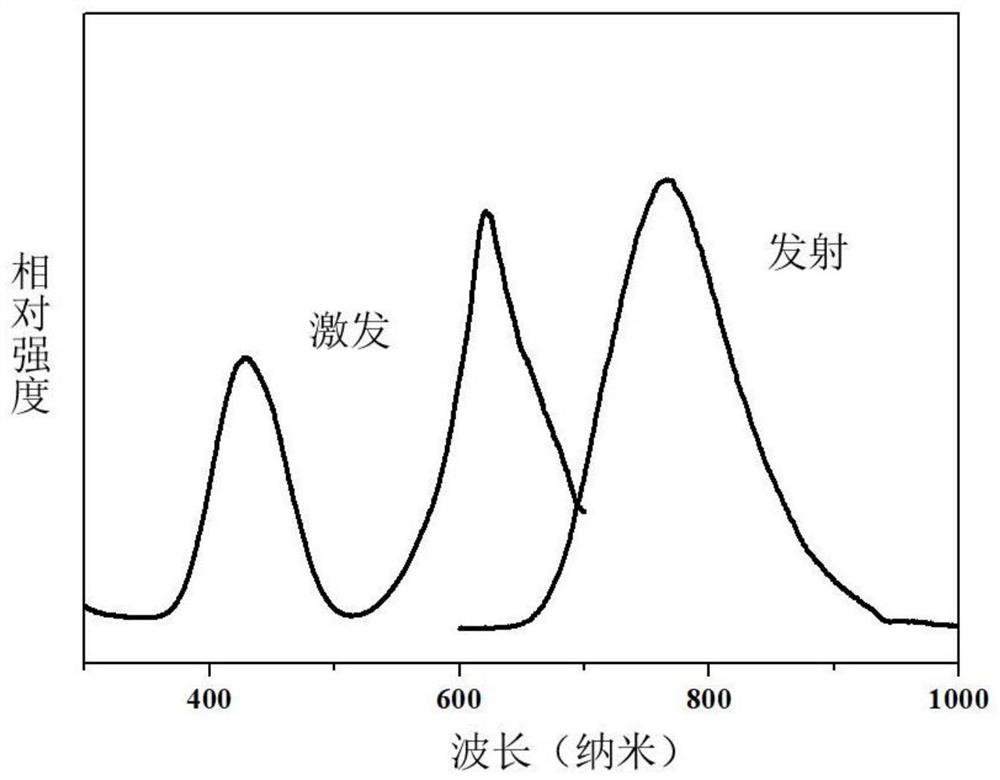

[0036] The excitation spectrum and emission spectrum of the far-red and near-infrared emitting fluoride fluorescent materials obtained in this embodiment are as follows: figure 1 shown.

[0037] An application of a far-red and near-infrared emitting fluoride fluorescent material...

Embodiment 2

[0039] A far-red and near-infrared emitting fluoride-based fluorescent material, the chemical expression of the fluorescent material is Na 3 al 0.96 f 6 : 0.04Cr, its preparation steps are as follows:

[0040] 1. Weigh 0.03mol of raw materials NaF, AlF 3 ·3H 2 O 0.0096mol, CrF 3 0.0004mol, weigh 20% of the total weight of raw material NH 4 F;

[0041] 2. After fully mixing the weighed raw materials, sinter at 700°C for 2 hours in an argon atmosphere to obtain a roasted product;

[0042] 3. After the roasted product is ground into powder and passed through a 200 mesh sieve, it is washed 3 times with deionized water and dried at 100°C to obtain the Na 3 al 0.96 f 6 : 0.04Cr phosphor.

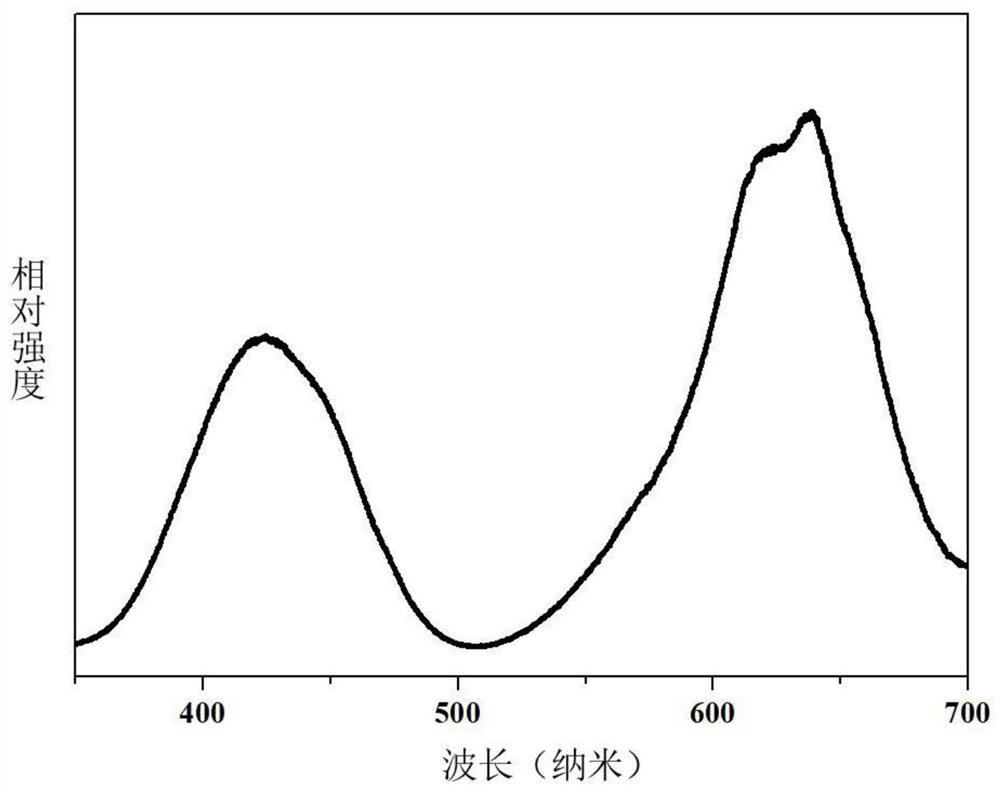

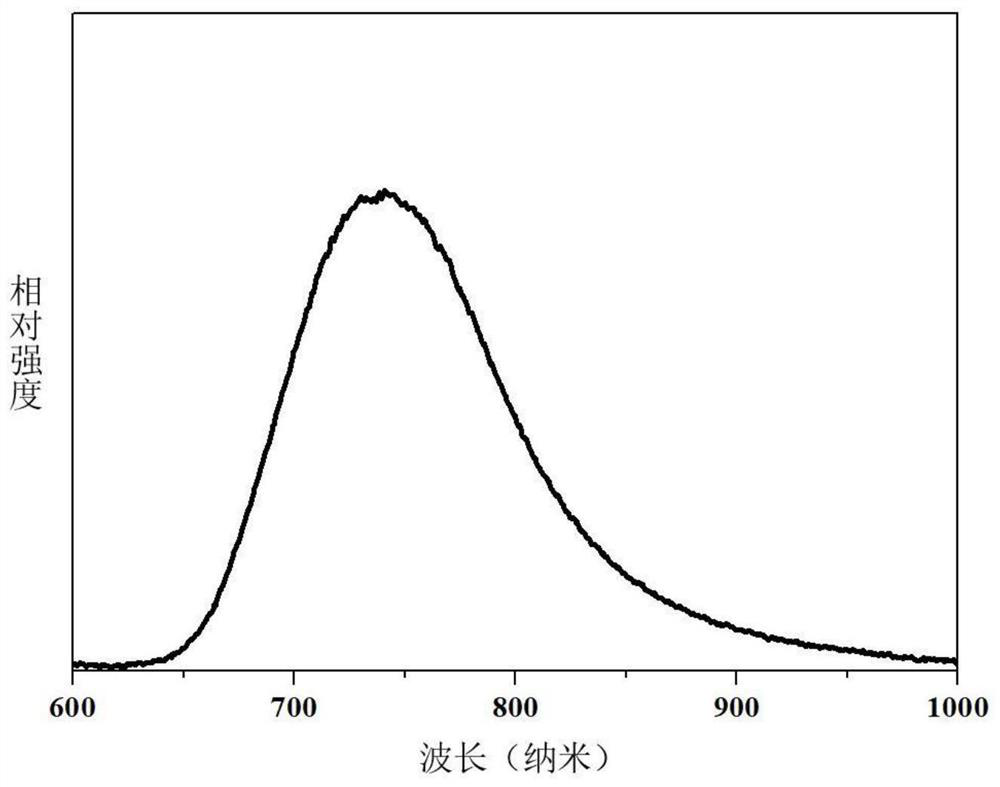

[0043] The excitation and emission spectra of the far-red and near-infrared emitting fluoride fluorescent materials obtained in this embodiment are shown in the attached figure 2 , 3 shown.

[0044] An application of a far-red and near-infrared emitting fluoride fluorescent material...

Embodiment 3

[0046] A far-red and near-infrared emitting fluoride-based fluorescent material, the chemical expression of the fluorescent material is Na 2.5 Li 0.5 al 0.98 f 6: 0.02Cr, its preparation steps are as follows:

[0047] 1. Weigh raw materials NaF 0.025mol, LiF 0.005mol, AlF 3 ·3H 2 O 0.0098mol, CrF 3 0.0002mol, weigh 30% of the total weight of raw materials NH 4 F;

[0048] 2. After fully mixing the weighed raw materials, sinter at 720°C for 5 hours in an argon atmosphere to obtain a roasted product;

[0049] 3. After the roasted product is ground into powder and passed through a 200 mesh sieve, it is washed 3 times with deionized water and dried at 100°C to obtain the Na 2.5 Li 0.5 al 0.98 f 6 : 0.02Cr phosphor.

[0050] The excitation and emission spectra of the far-red and near-infrared emitting fluoride fluorescent materials obtained in this embodiment are shown in the attached image 3 , 4 shown.

[0051] An application of a far-red and near-infrared emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com