Lubricant composition and preparation method thereof and trace lubricant prepared from lubricant composition

A lubricant composition and a technology for trace lubricants, which are applied in the field of lubrication, can solve the problems affecting the health of operators, pollution of processing places and environment, and large amount of lubricant used, and achieve remarkable environmental protection effect, remarkable environmental protection, Good lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 298.55g (1mol) of isoeicosanol and 192.14g (1mol) of citric acid into the reaction kettle together, stir and heat to 220°C, and after fully reacting for 3 hours, add polyethylene glycol (PEG1000 ) 140g, keeping the reaction temperature at 220°C, reacting for 2 hours, decompressing and discharging water after the reaction, which is a lubricant composition.

[0031] The lubricant composition prepared in Example 1 can be directly used as a micro-quantity lubricant, and it can be directly used in a micro-quantity lubrication device after adding 3 times of water and stirring until it becomes transparent.

Embodiment 2

[0033] Weigh 372.76g (2mol) of lauryl alcohol, 192.14g (1mol) of citric acid, and 2.8g of germanium dioxide and add them to the reaction kettle together, stir and heat to 200°C, and fully react for 5 hours. 120g of alcohol (PEG800) was kept at a reaction temperature of 200°C for 3 hours, and after the reaction, the water was depressurized and discharged to form a lubricant composition.

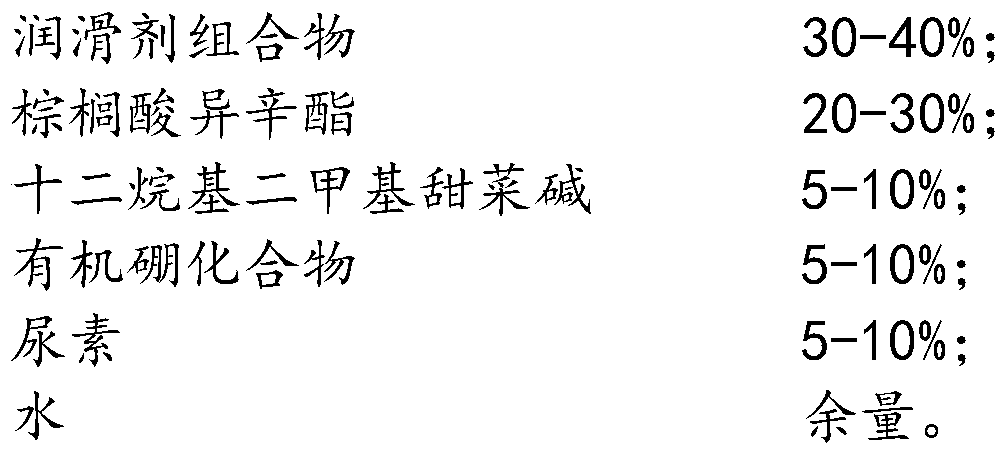

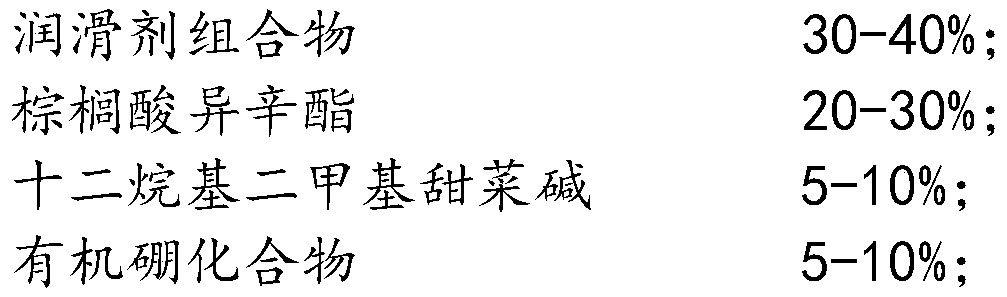

[0034] Weigh 100g of urea and dissolve it in 150g of water, add 400g of the above lubricant composition, 200g of isooctyl palmitate, 100g of dodecyldimethyl betaine, and 50g of organoboron compound, mix and stir at 60°C until transparent. A micro lubricant.

[0035] The preparation method of the above organoboron compound: weigh 100g of oleamide, 30g of boric acid, and 20g of hydroxyethylethanolamine, mix them at 100°C and stir for 1 hour, then vacuumize and decompress and heat up to 120°C (keep the pressure in the container not greater than 100mmHg), Stir for 2 hours, and filter the precipit...

Embodiment 3

[0038] Weigh 321.59g (1.5mol) of myristyl alcohol, 192.14g (1mol) of citric acid, and 0.6g of germanium dioxide into the reaction kettle, stir and heat to 208°C, and fully react for 4 hours. 130 g of polyethylene glycol (PEG600) is kept at a reaction temperature of 208° C., reacted for 2.5 hours, and after the reaction is decompressed to discharge water, which is a lubricant composition.

[0039] Weigh 50g of urea and dissolve it in 200g of water, add 300g of the above lubricant composition, 300g of isooctyl palmitate, 50g of dodecyldimethyl betaine, and 100g of organoboron compound, mix and stir at 50°C until transparent. A micro lubricant.

[0040] The preparation method of the above organoboron compound: weigh 100g of oleamide, 28g of boric acid, and 18g of hydroxyethylethanolamine, mix them at 99°C and stir for 1 hour, then vacuumize and decompress and heat up to 115°C (keep the pressure in the container not greater than 100mmHg), Stir for 2.5 hours, and filter the precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com