Cement paste concentration real-time regulation and control device for cement-soil mixing pile and use method thereof

A cement-soil mixing pile and real-time control technology, which is applied to sheet pile walls, buildings, and infrastructure engineering, can solve the problems of cement waste, poor drilling in hard soil layers, and the inability to judge the degree of softness and hardness of the soil layer. Improve the strength of cement and soil, reduce the cost of the project, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

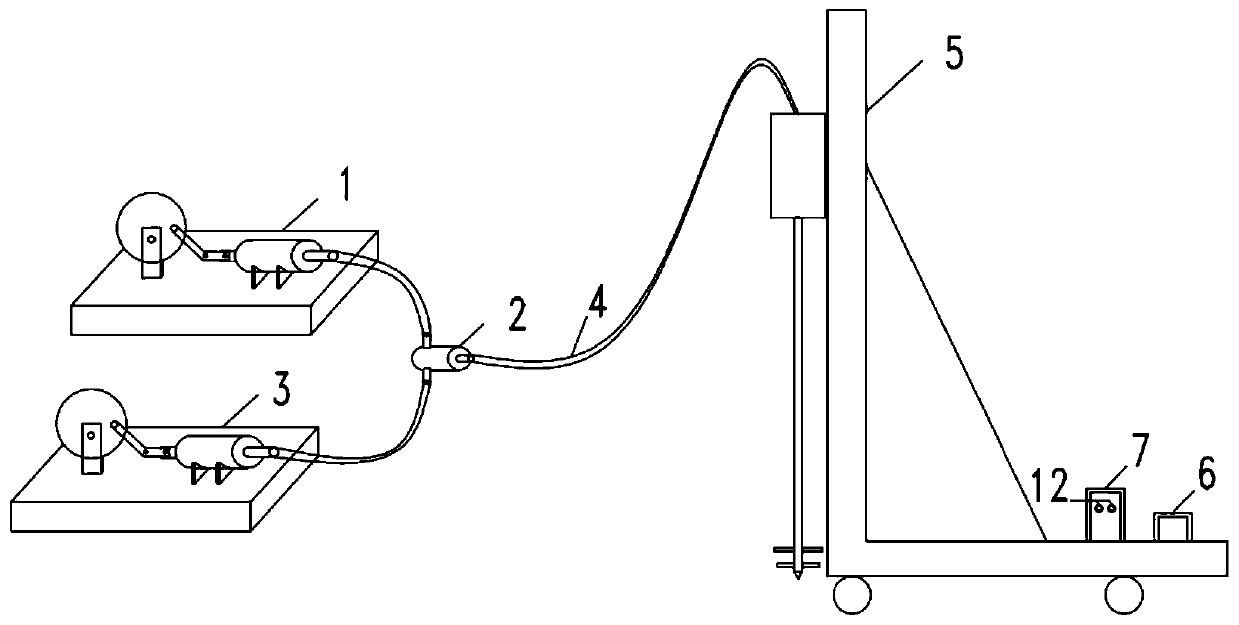

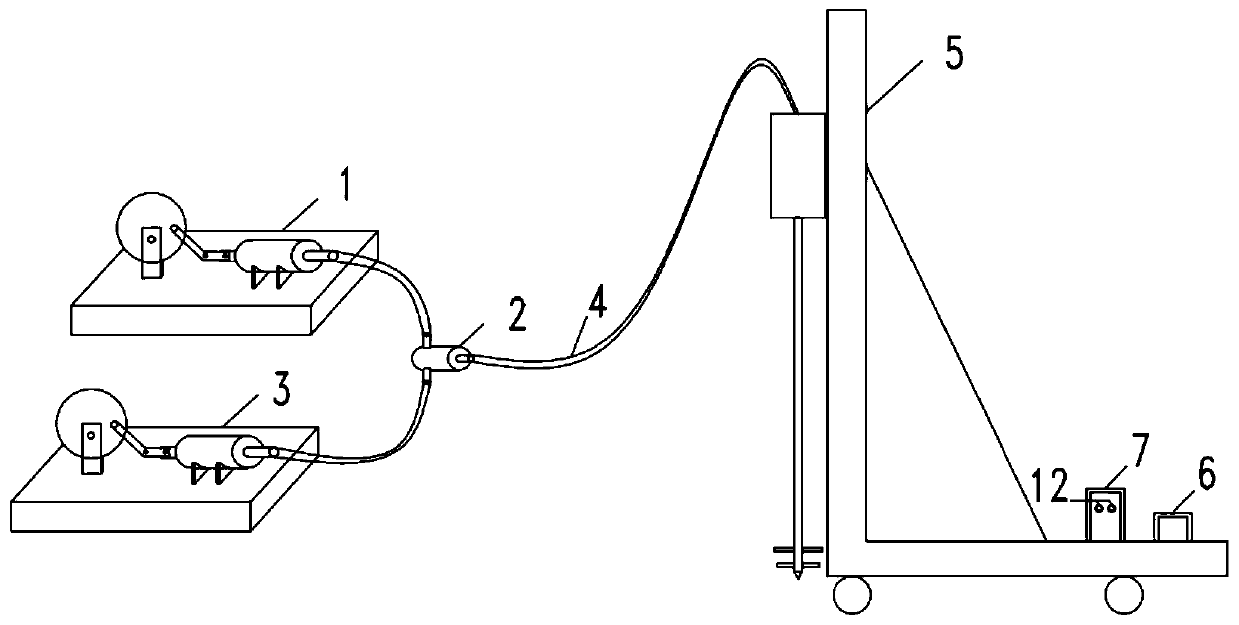

[0029] Such as figure 1 As shown, a cement-soil mixing pile cement slurry concentration real-time control device includes a current sensor, a monitoring host 6, a slurry pump 1, a frequency conversion pump 3 and a tee joint 2, and the current sensor is installed in the control cabinet 7 of the pile driver. Before use, adjust the original current analysis program in the monitoring host according to the geological survey data of the construction site and local construction experience. After the test pile debugging confirms that it can operate normally, the cement-soil mixing pile construction can be started. During construction, the current sensor collects the current value of the drill pipe inside and outside the pile driver and transmits it to the monitoring host. The monitoring host analyzes the current value and change characteristics, obtains the softness and hardness of the soil layer at the depth of the drill bit, and calculates that the soil layer reaches the design stren...

Embodiment 2

[0032] A city road foundation treatment project is designed to use two-way cement-soil mixing piles for reinforcement. The design pile length is 12m, pile diameter is 600mm, pile spacing is 1.5m, and the characteristic value of the bearing capacity of the composite foundation is 85kPa. Geological survey data show that the soil layers of the site from top to bottom are: ②-1 layer: silt, layer thickness 2.2-3.5m; ③-1 layer: clay, layer thickness 3.5-4.8m; ④-1 layer: silt, layer thickness About 3.0m; ④-2b layer: clay, layer thickness 2.0-3.0m. The characteristic values of natural foundation bearing capacity of the above four soil layers are 40kPa, 120kPa, 40kPa and 130kPa respectively.

[0033]The on-site two-way cement-soil mixing pile machine is equipped with a cement slurry concentration real-time control device, and the current analysis program is compiled according to the geological survey data, installed in the monitoring host 6, and the construction starts after the test...

Embodiment 3

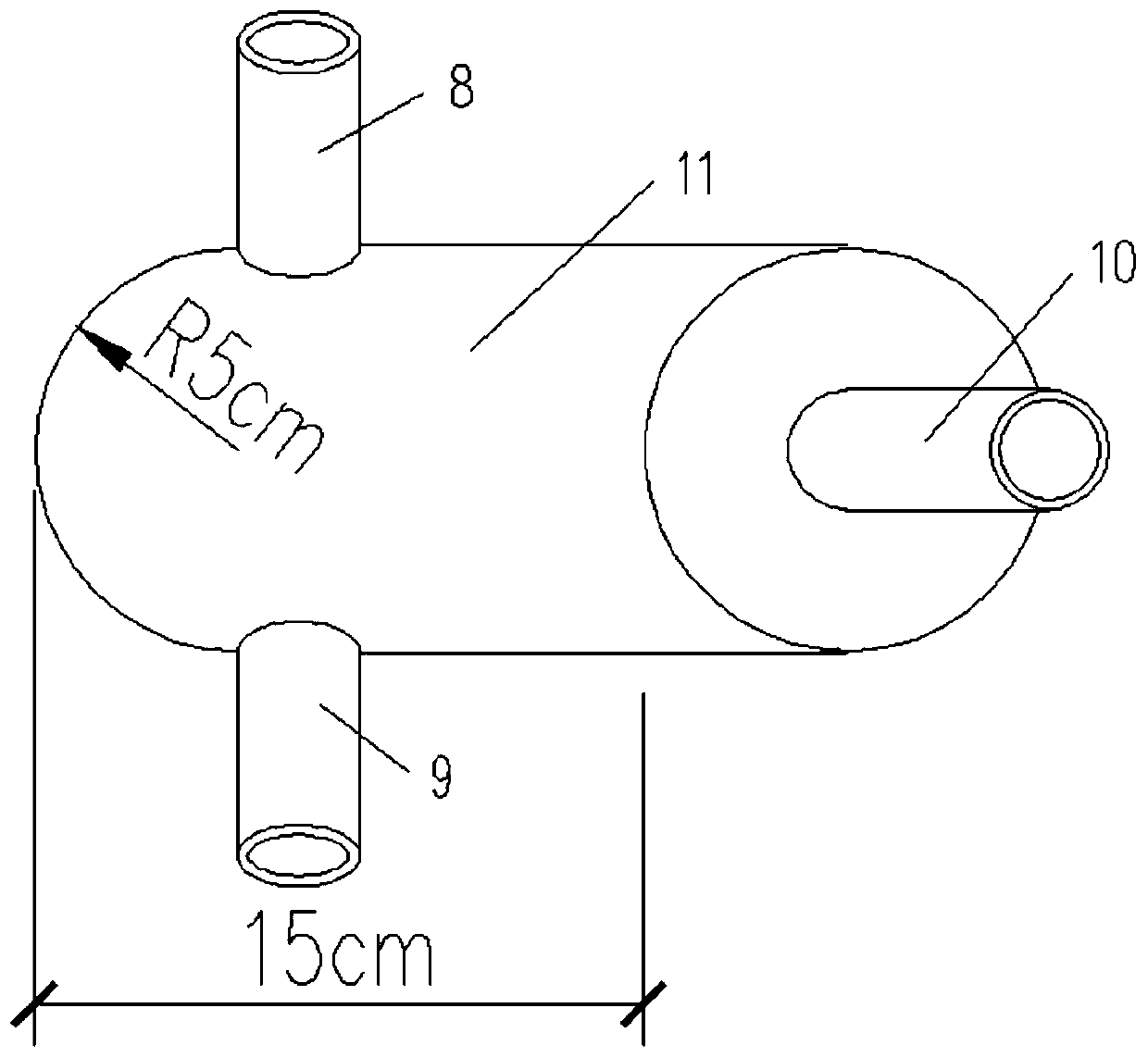

[0041] Such as figure 2 As shown, the tee joint 2 is a cylindrical chamber in the middle of the joint, with a cross-sectional radius of 5 cm and a length of 15 cm. The cement slurry and water enter the tee joint from the slurry inlet 8 and the water inlet 9 respectively, and under the action of the pumping pressure Next, after the cement slurry and water mixing chamber 11 are mixed quickly and evenly, the three-way joint 2 is sprayed out from the slurry outlet 10, and is transported to the cement-soil mixing pile machine 5 through the slurry delivery hose 4.

[0042] The purpose of the present invention is to provide a real-time control device for the cement slurry concentration of the cement-soil mixing pile and its use method, so as to adjust the cement slurry concentration in real time according to the actual soil layer softness and hardness at the depth of the drill bit, so as to ensure the maximum utilization of the soil layer in the soft soil layer The water in the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com