Sea-mixed sea-cured reinforced concrete adopting stainless steel coated steel bars

A reinforced concrete and stainless steel technology, applied in the field of reinforced concrete, can solve the problems of high price, high cost, and low yield strength of stainless steel bars, and achieve the effects of reducing transportation costs, excellent anti-corrosion performance, and reducing workload

Inactive Publication Date: 2019-06-21

HUNAN 3T NEW MATERIAL

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the yield strength of stainless steel bars is low and the price is expensive. In actual use, the reinforcement ratio must be increased to ensure the strength. This method is costly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

[0068] In embodiment 1-3, the mixing ratio of each raw material composition of concrete is such as table 2:

[0069] Cement: sea sand + coral reef debris: sea water Example 1 1:3:0.45 Example 2 1:2.8:0.4 Example 3 1:3.3:0.5

[0070] Among them, the mixing ratio of sea sand and coral reef debris is 1:1.3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

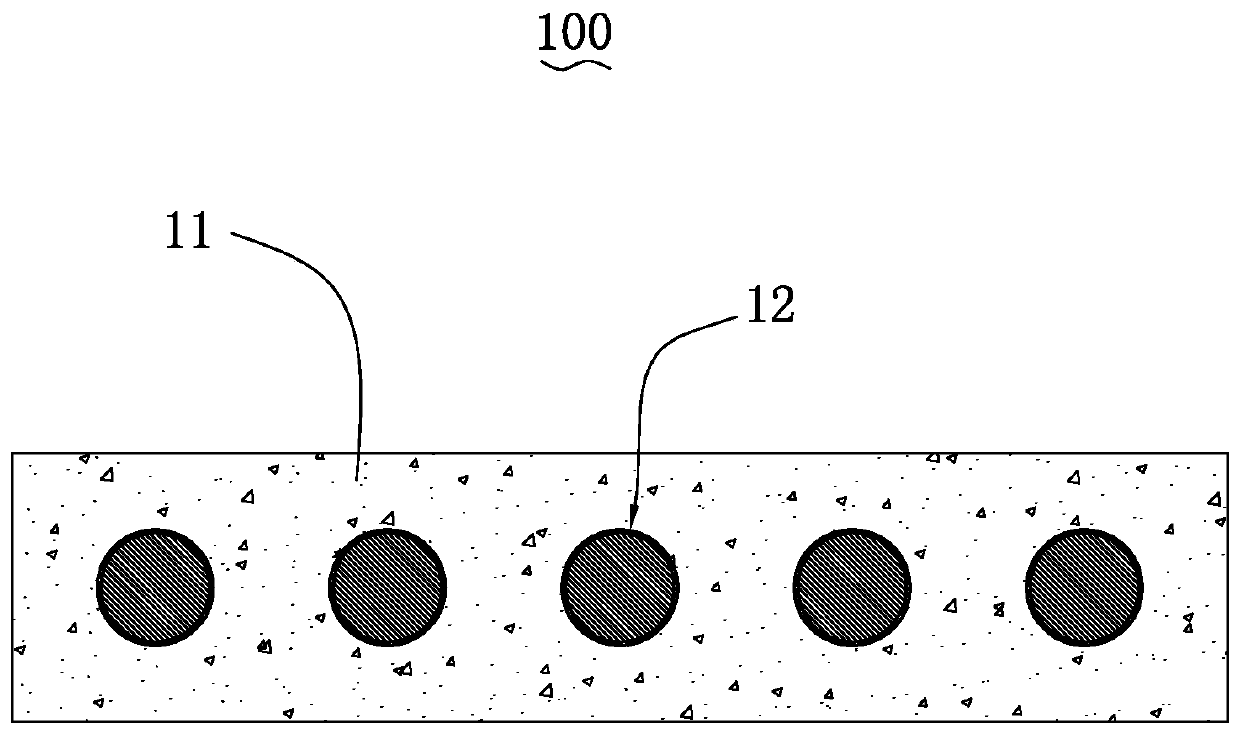

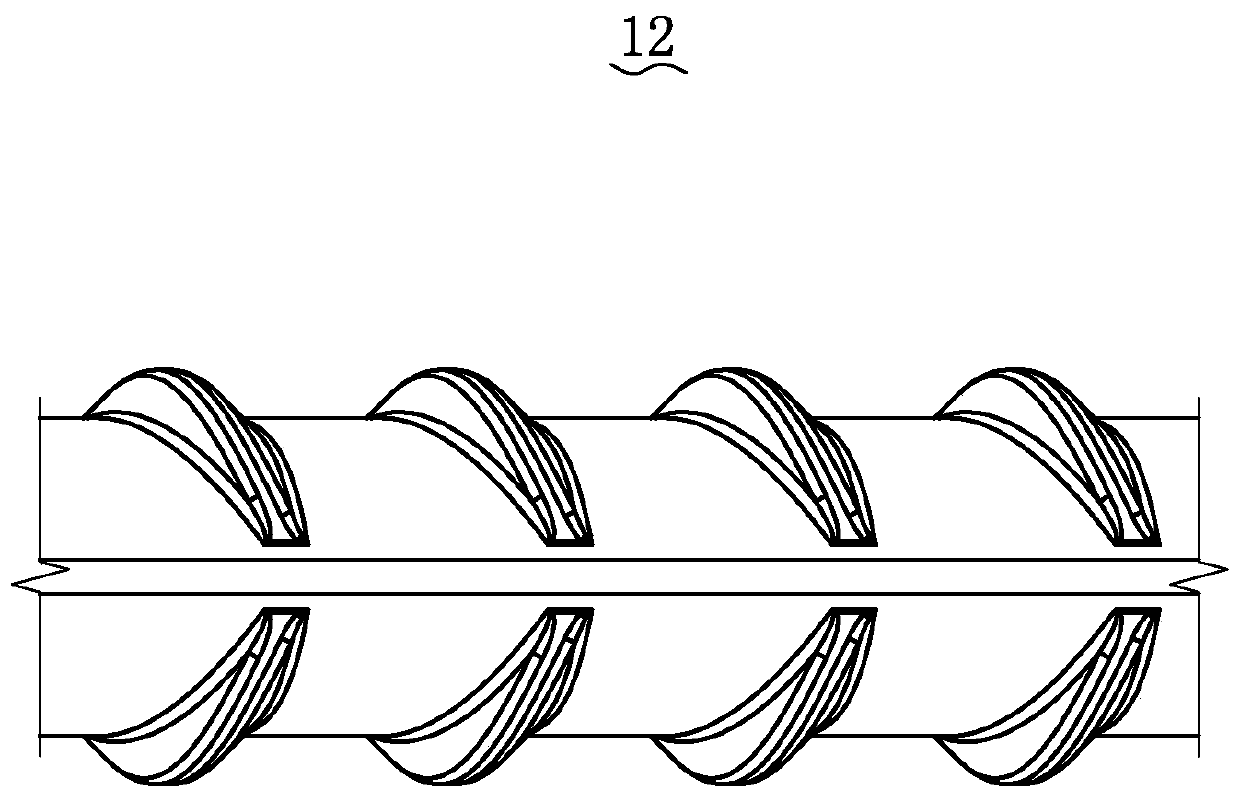

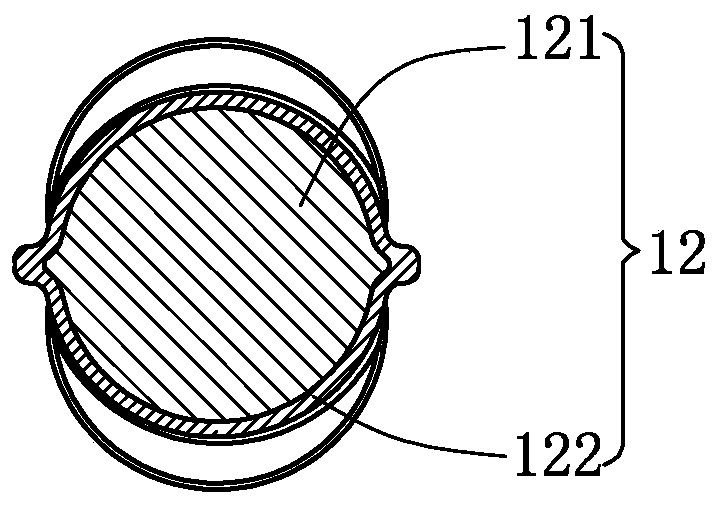

The invention discloses sea-mixed sea-cured reinforced concrete adopting stainless steel coated steel bars. The concrete comprises a concrete base body and coated steel bars arranged in the concrete base body, and the concrete base body is prepared from cement as a main cementing material, sea sand and coral reef chippings as aggregates and seawater as mixing water; and each coated steel bar comprises a core steel bar and a stainless steel coating layer coated on the surface of the core steel bar. According to the sea-mixed sea-culture reinforced concrete adopting the stainless steel coated steel bars, the stainless steel coating layer is coated on the surface of the common steel bar, so that the coated steel bars have excellent corrosion resistance, and the reinforced concrete has excellent marine chloride corrosion resistance; and the core steel bars of the coated steel bars are threaded steel carbon steel bars, so that the coated steel bars have the same mechanical property as common steel bars, high compressive strength, high tensile strength and high yield strength of the reinforced concrete are ensured, and the amount of reinforcements does not need to be additionally increased.

Description

technical field [0001] The invention relates to the technical field of reinforced concrete, in particular to a sea-mixed and sea-raised reinforced concrete using stainless steel clad steel bars. Background technique [0002] At present, the durability of concrete structures has been paid more and more attention, and the corrosion of steel bars is the most important factor leading to the deterioration of concrete structures. The main factors leading to the deterioration of concrete structures are chloride ion corrosion, concrete carbonation, sulfate attack, freeze-thaw damage, wave impact, etc. Among them, chloride ion corrosion is the most important factor causing steel bar corrosion. The free chloride ions in the concrete structure react chemically with the steel bars, causing the steel bars to corrode and expand along the bars and cause cracks in the concrete, reducing the durability and design service life of the concrete structure. Therefore, in concrete production, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D15/00E02D15/02C04B28/00

Inventor 向勇曾麟芳黄玲谢昭昭

Owner HUNAN 3T NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com