Quick-split type H-shaped steel concrete beam column connection node

A beam-column connection and H-beam technology, which is applied in construction, building structure, and building material processing, etc., can solve the problems of high drilling positioning accuracy, decreased column stability after drilling, and concrete extrusion damage, etc. The effect of on-site construction efficiency, reduction of on-site welding volume, and improvement of bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with accompanying drawing:

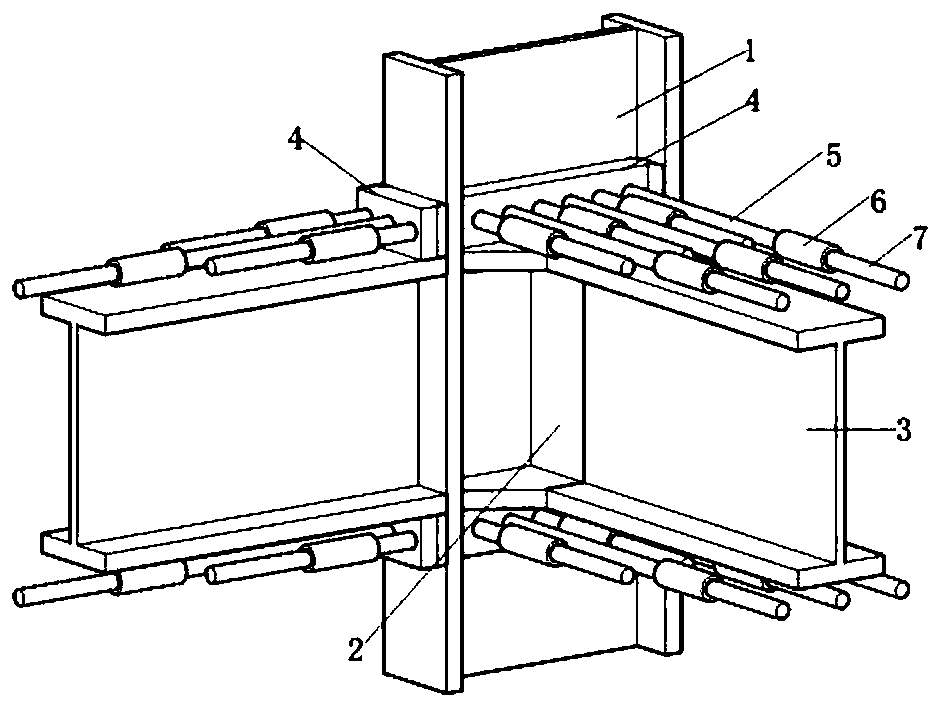

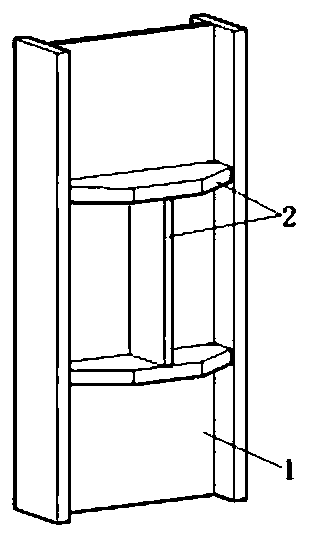

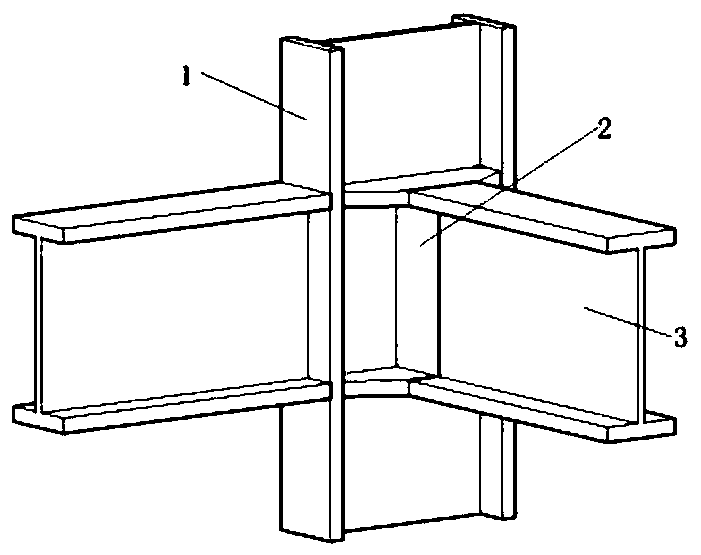

[0029] see Figure 1 to Figure 8 , a quick-assembled H-shaped steel concrete beam-column connection node, including H-shaped steel column 1, connecting plate 4, stiffening member 2, H-shaped steel beam 3 and reinforcing rib; any flange surface of H-shaped steel column 1 is fixed and vertically arranged There are H-shaped steel beams 3, connecting plates 4 are respectively fixed on the flanges of the H-shaped steel columns 1 at the contact points between the upper and lower flanges of the H-shaped steel beams 3 and the flanges of the H-shaped steel columns 1; any one of the H-shaped steel columns 1 H-shaped steel beams 3 are vertically fixed on the side web through stiffening members 2, and connecting plates 4 are arranged on the webs of H-shaped steel columns 1 at both ends of the stiffening member 2; several threaded holes are arranged on the connecting plates 4, and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com