A Centrifugal Pump Impeller with Non-smooth Surface and Its Efficiency and Noise Synergistic Design Method

A non-smooth surface, centrifugal pump impeller technology, applied in the field of centrifugal pumps, can solve the problems of ignoring the drag reduction effect of the blade trailing edge, and the structural size does not give a reasonable orthogonal comparison, so as to achieve a more reasonable design, reduce vibration and noise, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

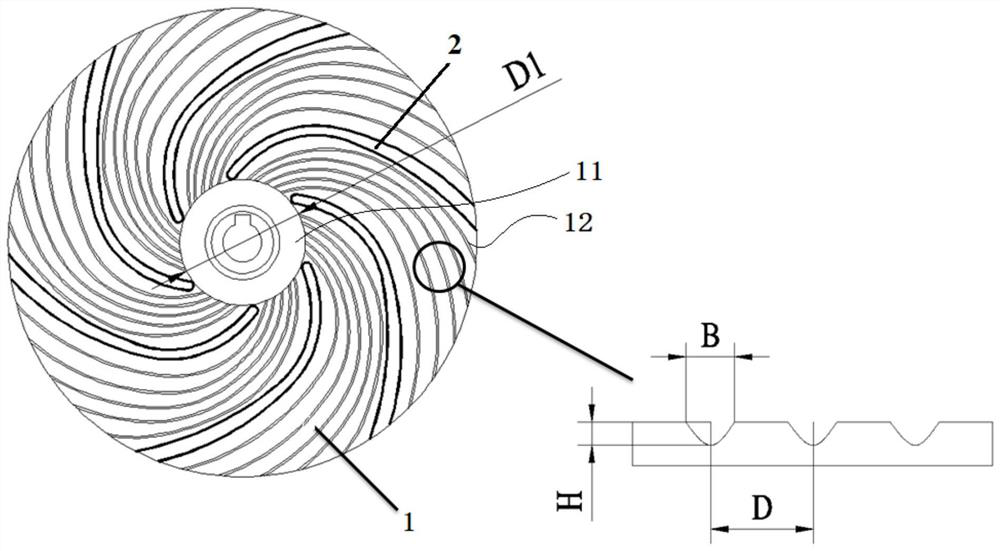

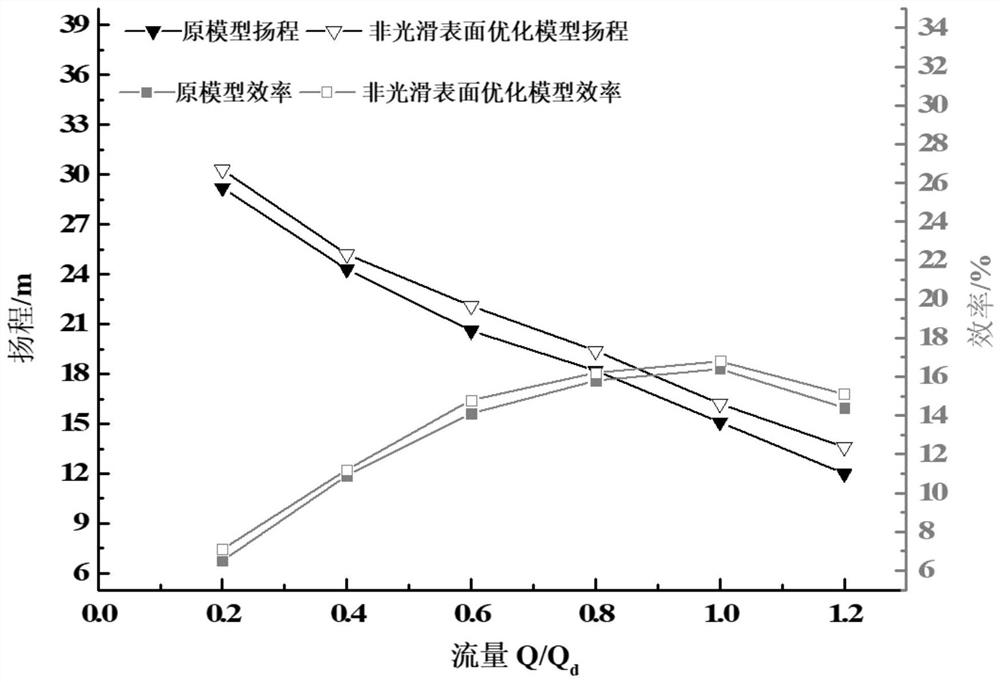

[0043] combine figure 1 and figure 2 As shown, a centrifugal pump impeller with non-smooth surface and its efficiency and noise co-improvement design method, including:

[0044] Cover plate 1, the cover plate 1 is the rear cover plate of the semi-open impeller, and the center part of the cover plate 1 has an inlet 11;

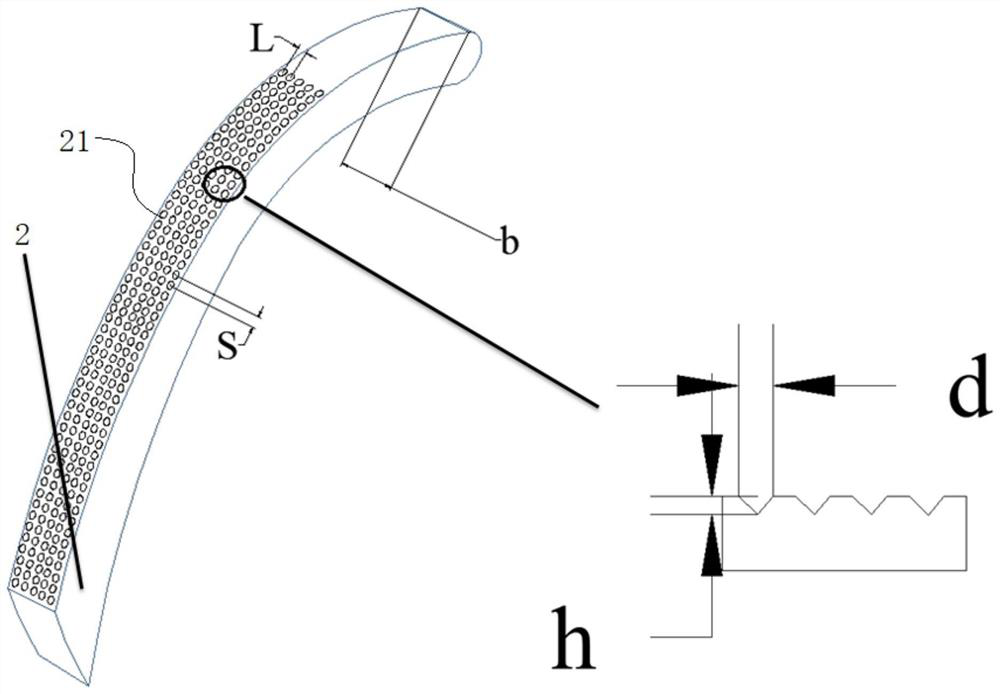

[0045] A plurality of blades 2, a plurality of blades 2 are arranged on one side of the cover plate 1 around the inlet 11, a plurality of blades 2 are distributed at intervals, and at least part of the working surfaces of the blades 2 have The first non-smooth surface structure 21 for drag resistance; the second non-smooth surface structure 12 for drag reduction is provided on at least part of the corresponding cover plate 1 between adjacent blades 2 . The fact that the plurality of blades 2 are arranged on one side of the cover plate 1 around the inlet 11 can also be understood as that the plurality of blades 2 are circumferentially distributed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com