A heliostat ultrasonic correction system and method

A correction system, ultrasonic technology, applied in the field of ultrasonic correction systems for heliostats, can solve problems such as no major breakthroughs, high operation and maintenance costs, frequent corrections, etc., to achieve maximum use of power generation resources, low operation and maintenance costs, shorten The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

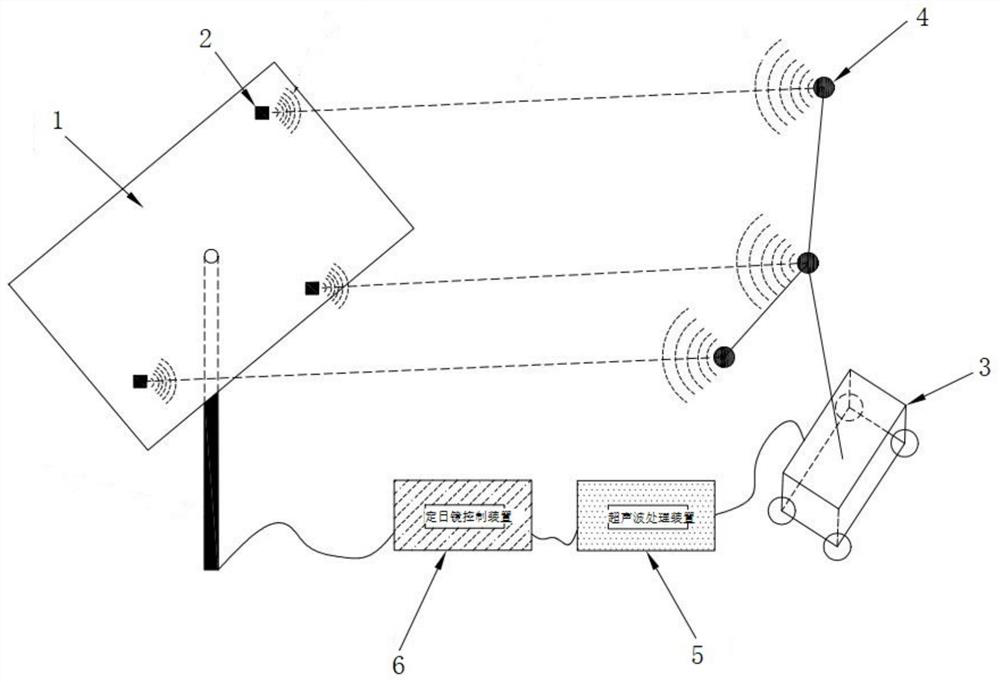

[0048] see figure 1 , the present embodiment provides a heliostat ultrasonic calibration system, comprising: a mobile fixture 3, an ultrasonic measurement device, an ultrasonic processing device 5, and a heliostat control device 6; wherein,

[0049] The ultrasonic measuring device, the ultrasonic processing device 5 and the heliostat control device 6 are installed and fixed on the mobile fixing device 3;

[0050] Ultrasonic measuring device, including at least three transmitting and receiving terminals 4, each transmitting and receiving terminal 4 is used to transmit ultrasonic waves to a correction point 2 of the heliostat 1, and receive the ultrasonic waves reflected by the correction point 2, wherein each transmitting and receiving terminal The ultrasonic waves emitted by 4 are ultrasonic waves of different frequencies;

[0051] The ultrasonic processing device 5 is used to receive the emission time point and the receiving time point of the ultrasonic wave fed back by the ...

Embodiment 2

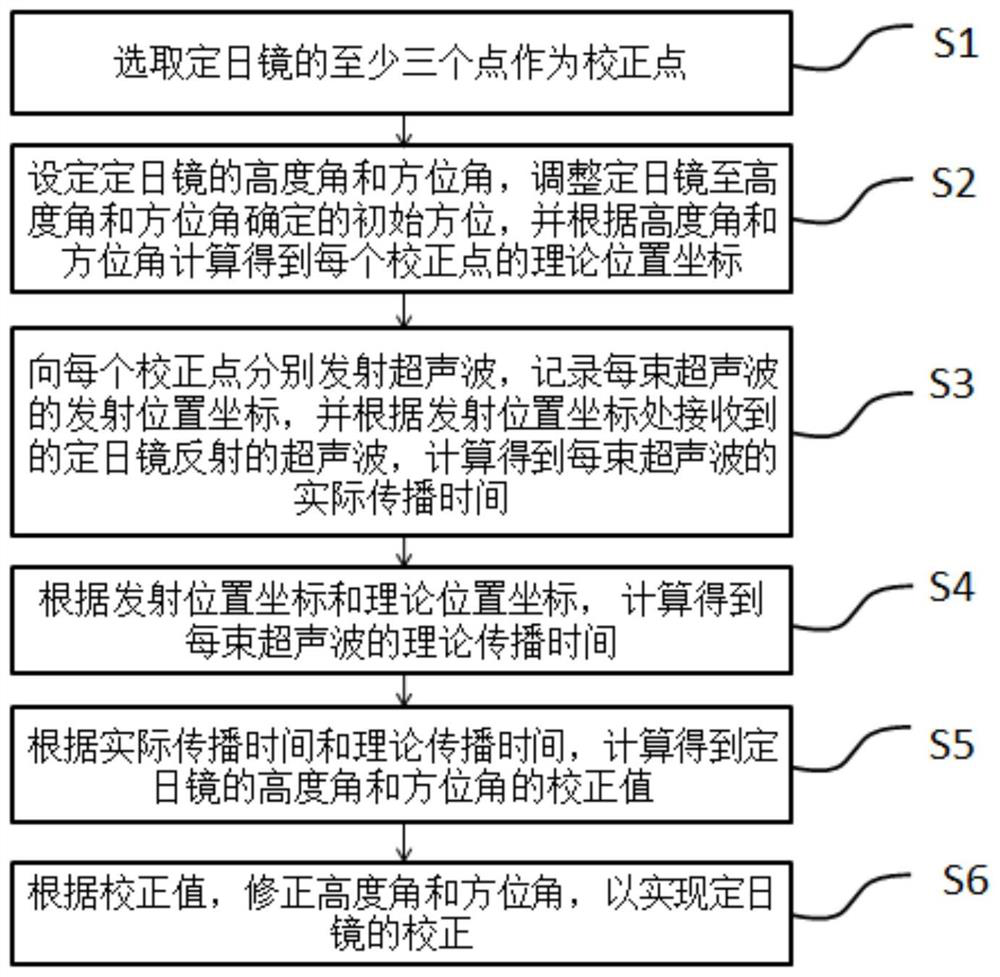

[0069] see figure 2 , the present embodiment provides a heliostat ultrasonic calibration method, comprising the following steps:

[0070] S1: Select at least three points of the heliostat as calibration points;

[0071] S2: Set the altitude angle and azimuth angle of the heliostat, adjust the heliostat to the initial orientation determined by the altitude angle and azimuth angle, and calculate the theoretical position coordinates of each calibration point according to the altitude angle and azimuth angle;

[0072] S3: Transmit ultrasonic waves to each calibration point, record the coordinates of the transmitting position of each beam of ultrasonic waves, and calculate the actual propagation time of each beam of ultrasonic waves according to the time nodes of the transmitted and received ultrasonic waves at the coordinates of the transmitting position;

[0073] S4: Calculate the theoretical propagation time of each beam of ultrasonic waves according to the coordinates of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com