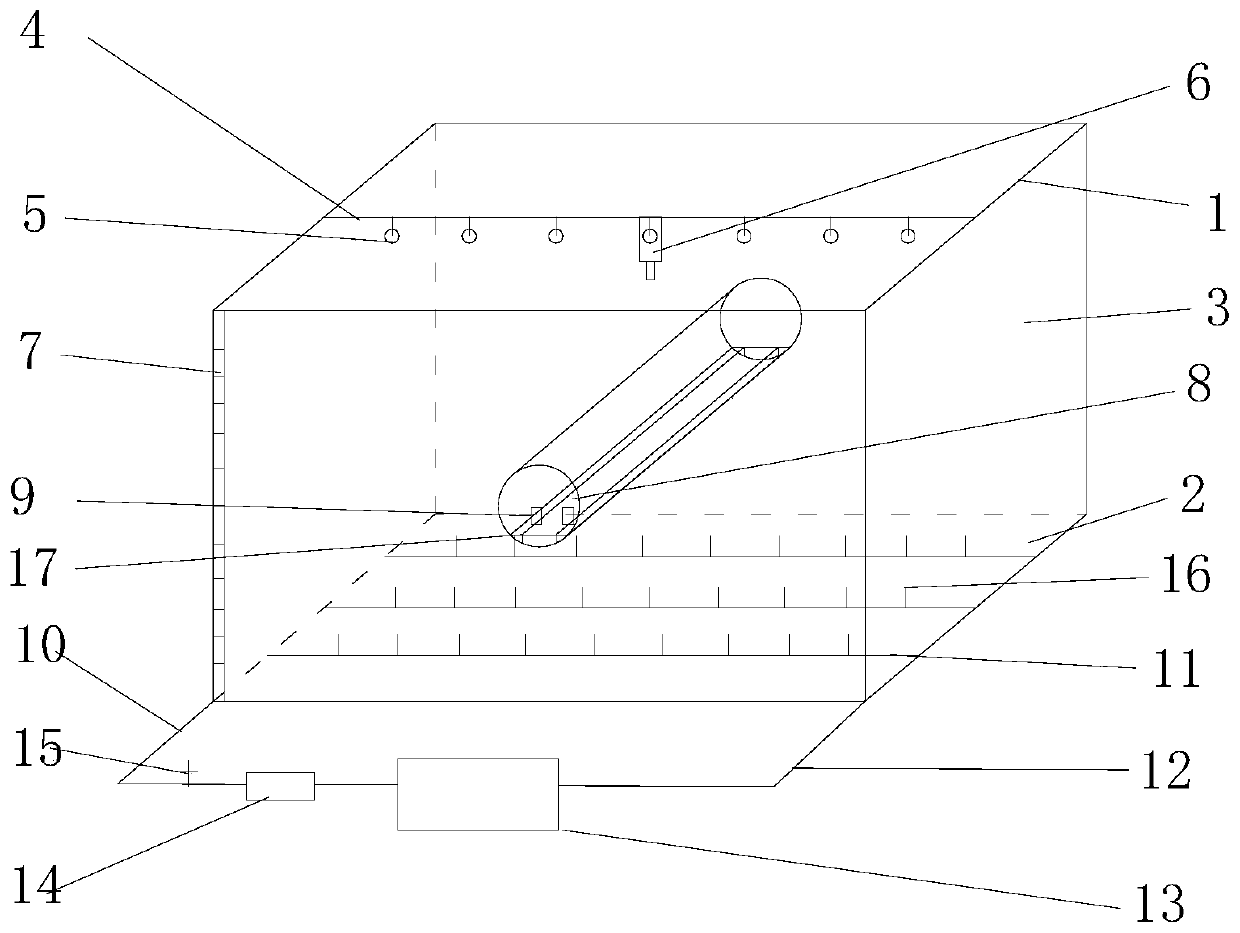

Loess subway tunnel surrounding rock immersion and dynamic load simulation system and test method

A simulation system, loess subway technology, applied in the direction of soil material testing, material inspection products, using stable tension/pressure testing material strength, etc., can solve the problem of local water seepage, mechanical parameter changes, and subway tunnel structures that cannot be simulated when underground pipelines burst Security threats and other issues, to achieve good promotion and application value, accurate test results, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

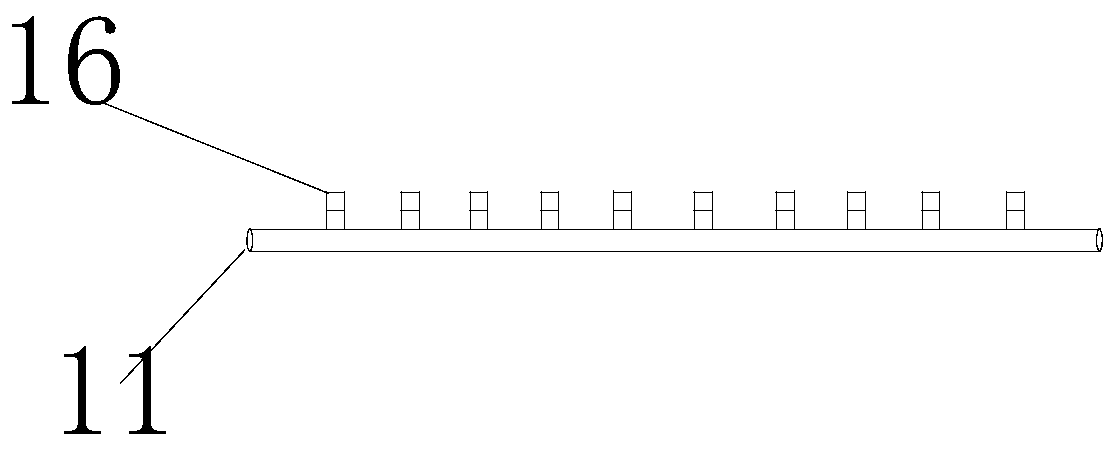

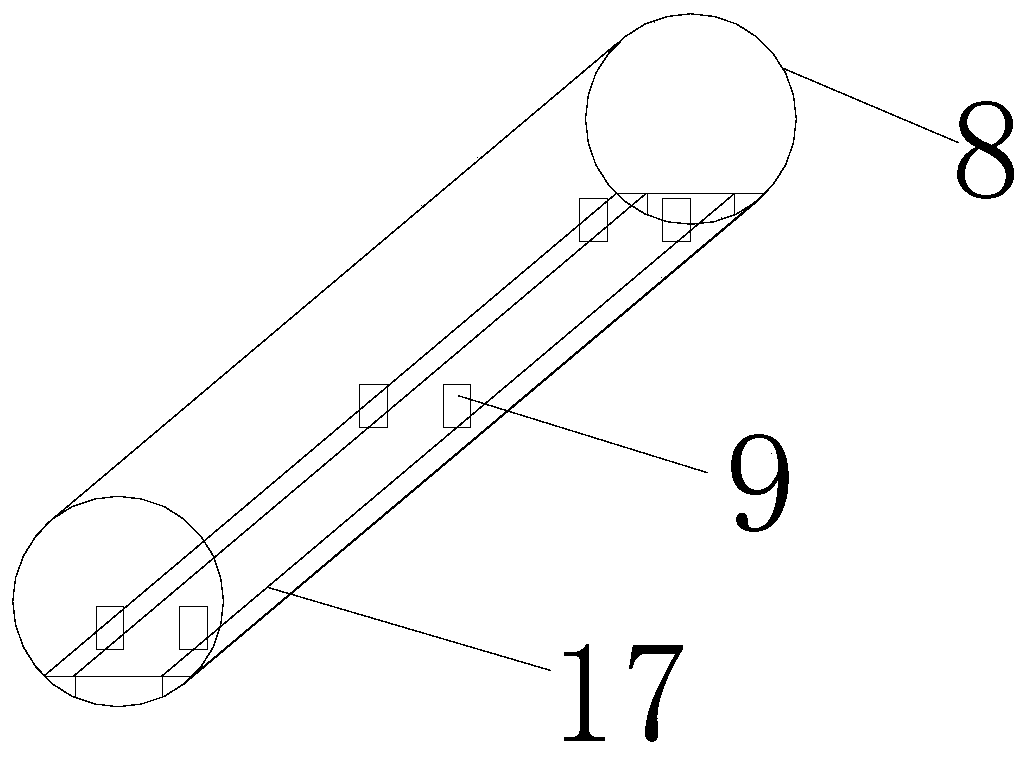

[0050] Regardless of the impact of dynamic loads, the impact of different submerged conditions on the subway tunnel structure is analyzed. The stratum around the tunnel is in an anhydrous state at the initial stage of tunnel excavation and construction and operation, and the mechanical parameters of the surrounding rock have not changed much. The tunnel can be considered to be in a healthy and safe state. However, with the increase of the operating period, various factors may cause the stratum around the tunnel to deteriorate due to flooding For example, the underground engineering construction causes the groundwater seepage path to change, causing the groundwater level to rise; the water in nearby rivers and underground rivers seeps into the tunnel; The impact of fissure seepage caused by heavy rainfall or discharge of domestic water. Therefore, during the long-term operation of the subway tunnel, various indicators such as the moisture content of the loess around the tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com