Reservoir brittleness evaluation method based on microscopic features of rock fragments and drilling parameters

A technology of drilling parameters and evaluation methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long test period, shale upgrading, and difficulty in coring, and achieve simple and effective evaluation methods, overcome limitations, and test costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

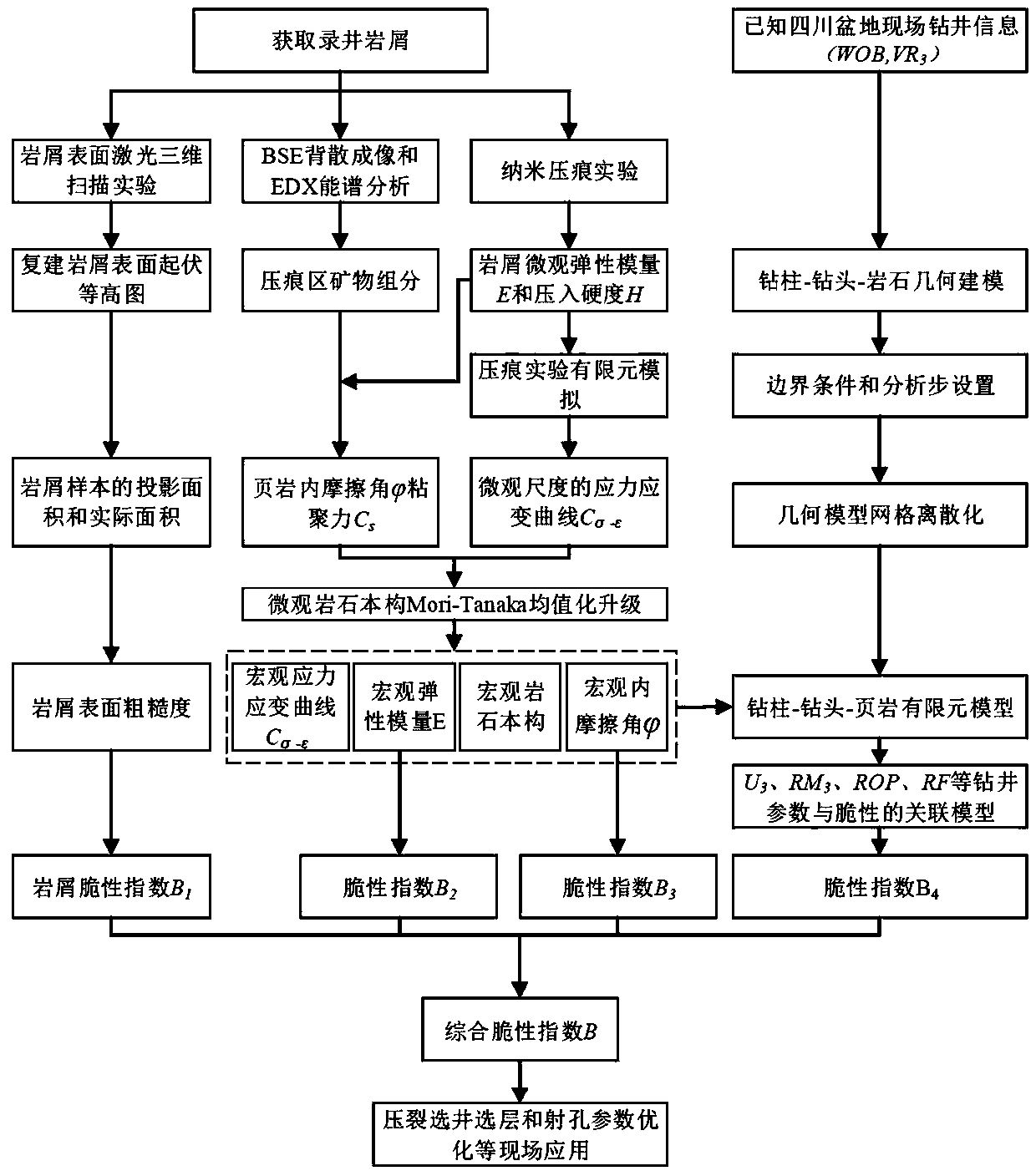

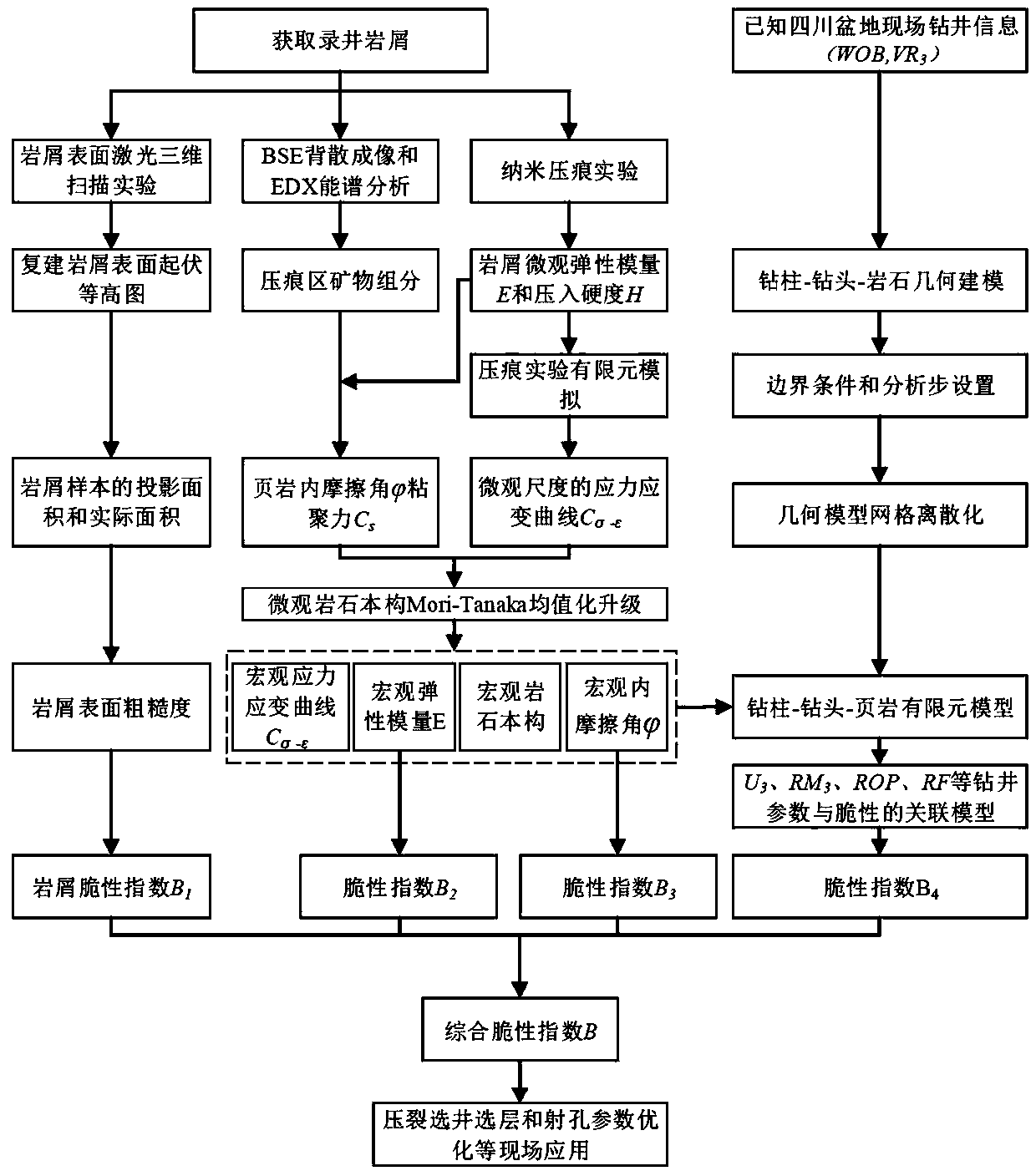

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0031] combine figure 1 As shown in , take the relevant data of well R in a certain area as an example to further illustrate.

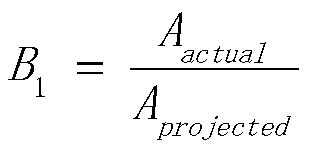

[0032] Step ①: Take shale cuttings at a specific depth of the reservoir, fish out the cuttings accurately, and measure the lateness time according to the specified time interval to ensure the continuity and representativeness of the cuttings. Eliminate false cuttings with fuzzy tones, inconspicuous edges and corners, and large individuals (non-horizontal), or directly use cored debris that has been cored downhole. After the original cuttings are obtained, the cuttings are cleaned and dried to remove the drilling fluid attached to the surface. According to the requirements of subsequent experiments, cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com