design method of molten iron KR desulfurization stirrer

A design method and agitator technology, which are applied in the fields of instrumentation, calculation, electrical digital data processing, etc., can solve the problem that the structural parameters of the agitator cannot be provided, and the reliable and effective stirring, mixing and dispersing conditions and reaction kinetic conditions of the KR stirred reactor cannot be guaranteed. , differences in technical and economic indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

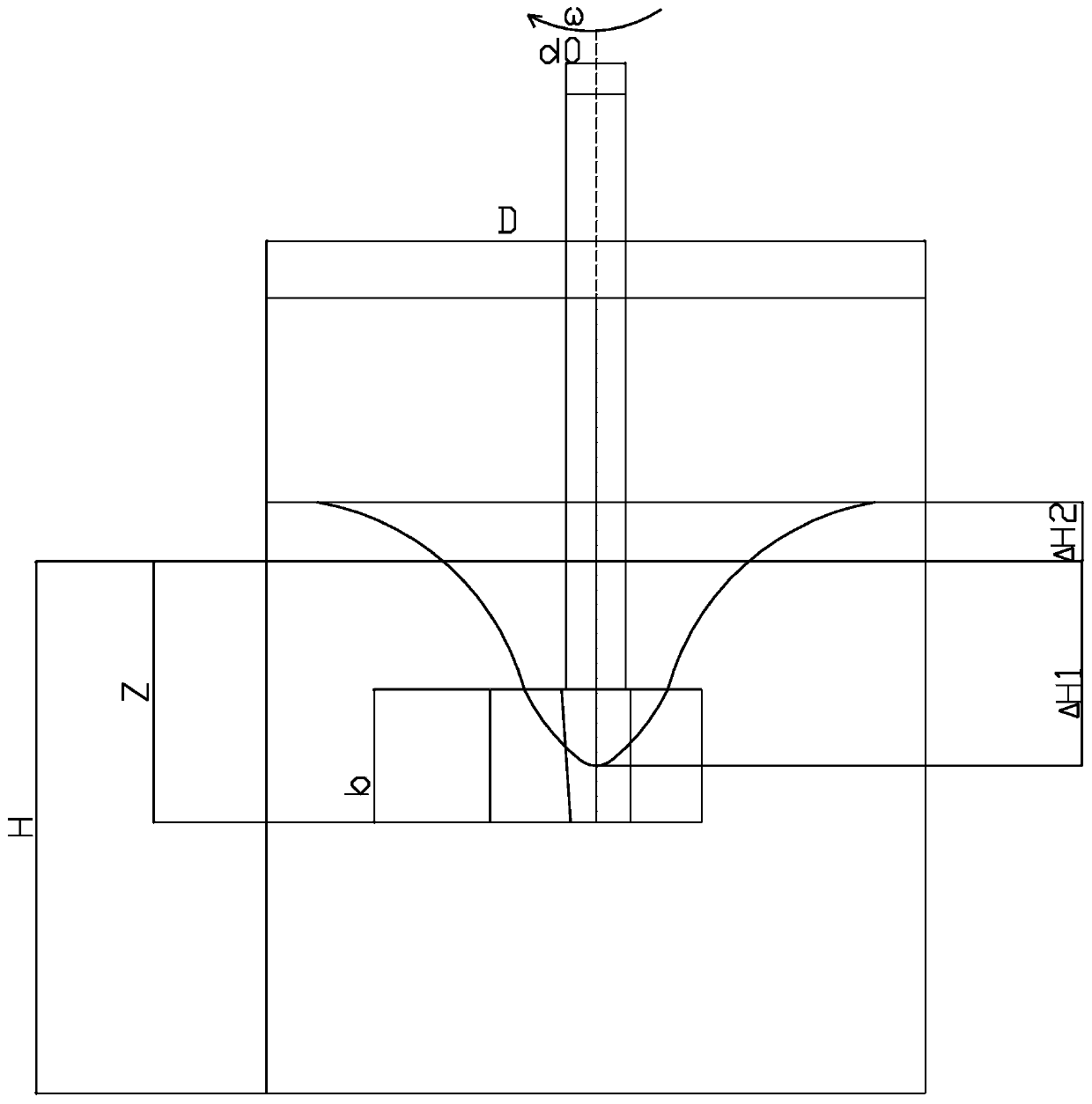

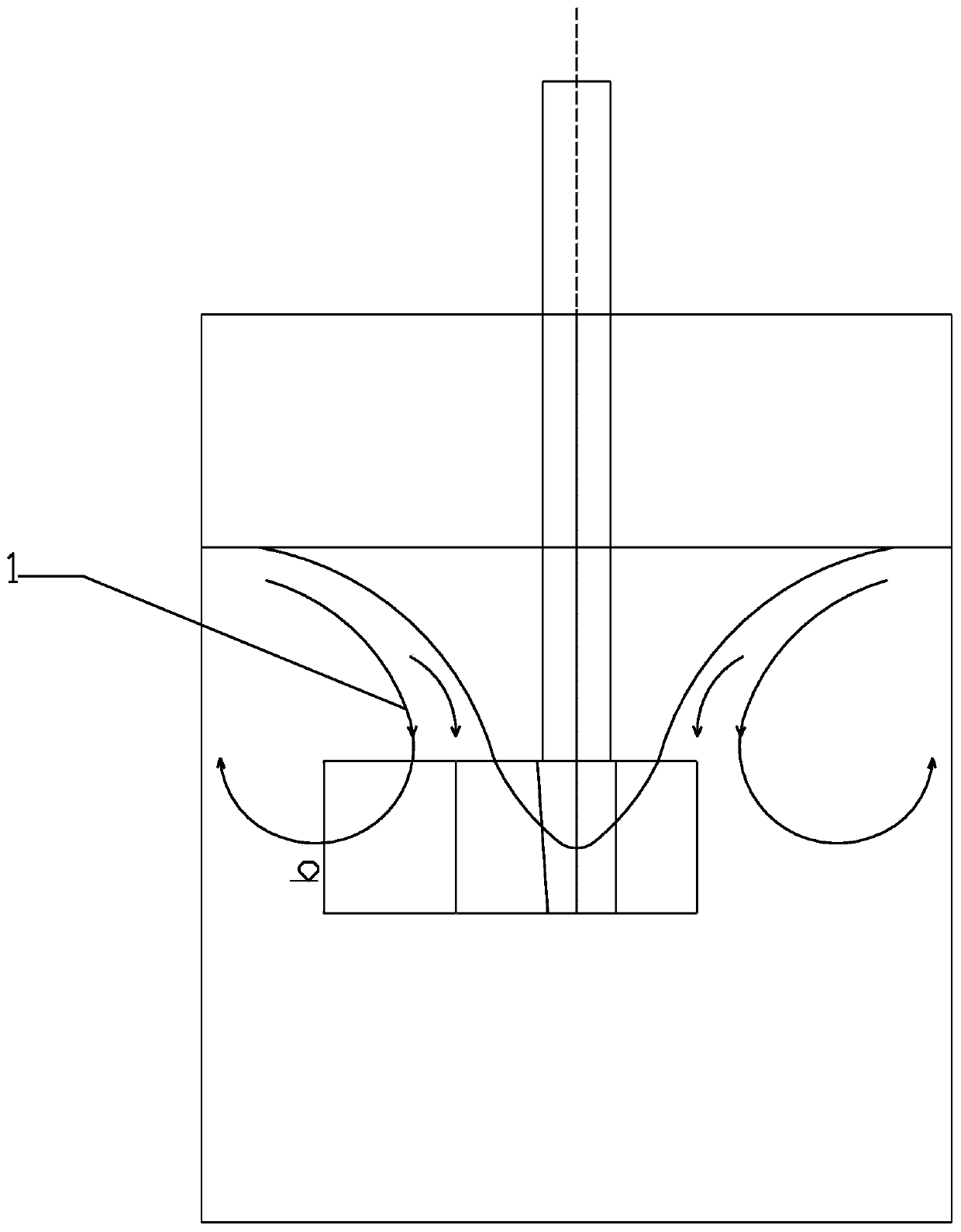

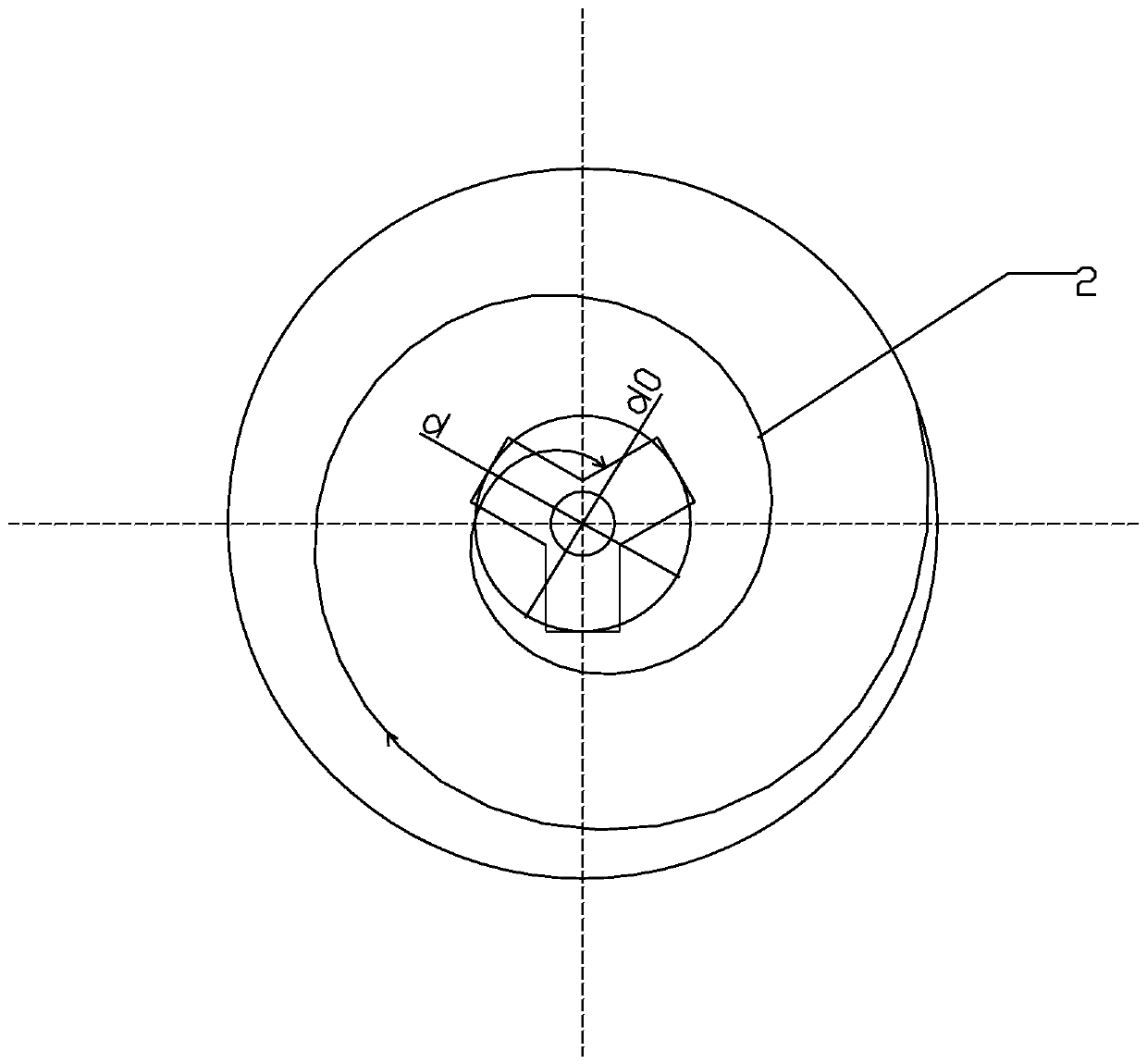

[0064] Such as Figure 1~4 The design method of the molten iron KR desulfurization agitator shown in a steel plant includes the following steps:

[0065] 1) According to the average diameter of the molten iron tank D = 3.853m and the rated maximum molten iron loading W, the calculated depth of the molten iron tank H = 4.255m;

[0066] 2) Empirical setting of the relationship between the structural parameters of the agitator

[0067] a. The experience settings for the new online mixer are as follows:

[0068] (1) The insertion depth Z of the agitator is: Z=(0.45~0.5)×H=1.915~2.128m, so as to ensure that the size of the molten iron mixing area in the molten iron tank is reasonable;

[0069] (2) The effective height b of the blade is: b=(0.625~0.700)×d, where d is the diameter of the impeller of the new agitator to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com