Magnesium oxychloride cement foam light wallboard and preparation method as well as equipment

A technology of magnesium oxychloride cement and lightweight wallboard, which is applied in the field of building materials, can solve the problems of inconvenient installation and construction, heavy weight, and low temperature resistance of wall core materials, and achieve convenient installation and construction, good fireproof performance, and high temperature resistance quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

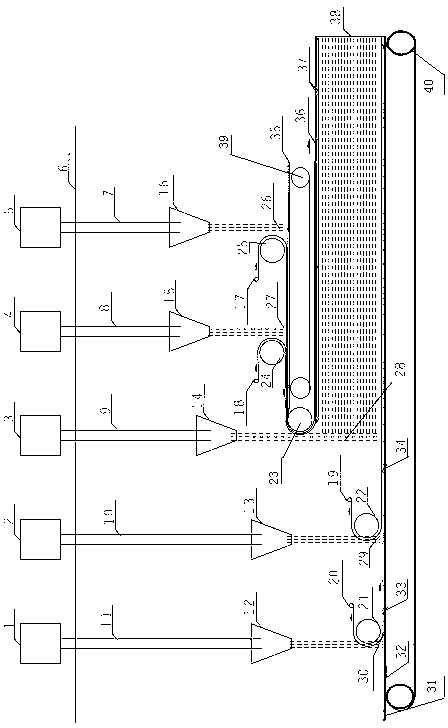

Image

Examples

Embodiment 1

[0022] Preparation of magnesium oxychloride cement foaming material:

[0023] 1) MgCl 2 Add water and stir to make brine with a Baume degree of 23 for subsequent use;

[0024] 2) Put the brine into the mixer before pouring the wallboard, then add magnesium oxide (MgO) with a purity of 85% and an activity of 65%, and stir while adding, the quality of brine is 45%, and the quality of magnesium oxide is 55% ;

[0025] 3) Then add sawdust and phosphoric acid, the amount of sawdust added is 5% of the mass of MgO, and the addition of phosphoric acid with a mass concentration of 85% is 0.5% of the mass of MgO;

[0026] 4) Then add high-temperature resistant polypropylene fiber and glass microsphere fly ash to increase the strength, and the addition amount of high temperature resistant polypropylene fiber and glass microsphere fly ash is 1% and 2% of the MgO mass respectively;

[0027] 5) Then add OP-10 of 0.5‰ of MgO quality;

[0028] 6) Finally, add 50 grams of foaming agent fo...

Embodiment 2

[0038] Preparation of magnesium oxychloride cement foaming material:

[0039] 1) MgCl 2 Add water and stir to make it generate brine with a Baume degree of 25 for subsequent use;

[0040] 2) Put the brine into the mixer before pouring the wallboard, then add magnesium oxide (MgO) with a purity of 85% and an activity of 65%, and stir while adding, the quality of brine is 50%, and the quality of magnesium oxide is 50% ;

[0041] 3) Then add sawdust and phosphoric acid, which are materials to prevent back halogenation, the amount of sawdust added is 15% of the mass of MgO, and the amount of phosphoric acid with a mass concentration of 85% is added to be 1.5% of the mass of MgO;

[0042] 4) Then add high-temperature resistant polypropylene fiber and glass microsphere fly ash to increase the strength, and the addition amount of high temperature resistant polypropylene fiber and glass microsphere fly ash is 1.5% and 5% of the MgO mass respectively;

[0043] 5) Then add 1.5‰ OP-10 o...

Embodiment 3

[0051] Preparation of magnesium oxychloride cement foaming material:

[0052] 1) MgCl 2 Add water and stir to make brine with a Baume degree of 27 for later use;

[0053] 2) Put the brine into the mixer before pouring the wallboard, then add magnesium oxide (MgO) with a purity of 85% and an activity of 65%, and stir while adding, the quality of brine is 49%, and the quality of magnesium oxide is 51% ;

[0054] 3) Then add sawdust and phosphoric acid, which are materials to prevent back halogenation, the amount of sawdust added is 20% of the mass of MgO, and the amount of phosphoric acid with a mass concentration of 85% is added to be 1% of the mass of MgO;

[0055] 4) Then add high-temperature resistant polypropylene fiber and glass microsphere fly ash to increase the strength, and the addition amount of high temperature resistant polypropylene fiber and glass microsphere fly ash is 2% and 6% of the MgO mass respectively;

[0056] 5) Then add 2‰ of MgO quality OP-10;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com