Hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as reducing catalyst selectivity, affecting target product yield, etc., to reduce interaction, Highly selective, interaction-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

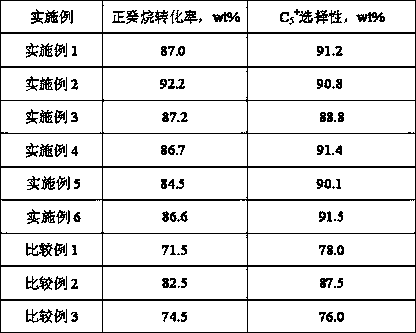

Examples

Embodiment 1

[0050] (1) Preparation of Mo-Co-P aqueous solution:

[0051] 1.9g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 5.2g of molybdenum trioxide and 1.9g of basic cobalt carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Co-P aqueous solution. where MoO 3 The concentration is 0.05g / mL, Co 2 o 3 The concentration of P is 0.01g / mL, and the concentration of P is 0.005g / mL.

[0052] (2) Preparation of catalyst:

[0053] 80.4g alumina carrier (pore volume 0.70mL / g, specific surface area 300m 2 / g, spherical shape, particle diameter 0.4mm~0.6mm) was added to 200mL cyclohexane solution containing 11.3g dodecyltrimethoxysilane, reacted at 50°C for 3.0h, dried at 70°C for 8h to obtain the catalyst Precursor A; then added to 200mL of 5# diesel oil, filtered after soaking for 30min, the obtained material was placed in a low-temperature reaction bath at 0°C, and then 150mL of an aqueous solut...

Embodiment 2

[0059] (1) Preparation of Mo-Co-P aqueous solution:

[0060] 4.5g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 15.5g of molybdenum trioxide and 5.7g of basic cobalt carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Co-P aqueous solution. where MoO 3 The concentration is 0.15g / mL, Co 2 o 3 The concentration of P is 0.03g / mL, and the concentration of P is 0.012g / mL.

[0061] (2) Preparation of catalyst:

[0062] 53.4g alumina carrier (pore volume 0.70mL / g, specific surface area 300m 2 / g, spherical shape, particle diameter 0.4mm~0.6mm) was added to 200mL cyclohexane solution containing 32.0g hexadecyltrimethoxysilane, reacted at 50°C for 3.0h, dried at 70°C for 8h to obtain the catalyst Precursor A; then added to 150mL of 0# diesel oil, soaked for 30min and then filtered, the obtained material was placed in a low-temperature reaction bath at -10°C, and then 150mL of an aqueou...

Embodiment 3

[0068] (1) Preparation of Mo-Co-P aqueous solution:

[0069] 7.6g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 20.7g of molybdenum trioxide and 9.4g of basic cobalt carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Co-P aqueous solution. where MoO 3 The concentration is 0.2g / mL, Co 2 o 3 The concentration of P is 0.05g / mL, and the concentration of P is 0.02g / mL.

[0070] (2) Preparation of catalyst:

[0071] 34.3g alumina carrier (pore volume 0.70mL / g, specific surface area 300m 2 / g, spherical shape, particle diameter 0.4mm~0.6mm) was added to 150mL cyclohexane solution containing 35.7g octadecyltrimethoxysilane, reacted at 50°C for 3.0h, dried at 70°C for 8h to obtain the catalyst Precursor A; then added to 150mL-10# diesel oil, filtered after soaking for 30min, the obtained material was placed in a low-temperature reaction bath at -20°C, and then 100mL of an aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com