Fully-automatic packaging robot for latex glove carton

A fully automatic packaging and latex glove technology, applied in packaging and other directions, can solve problems such as reducing labor efficiency, increasing labor costs, and internal medical article pollution, achieving the effect of reducing labor intensity and labor costs and improving the efficiency of carton packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

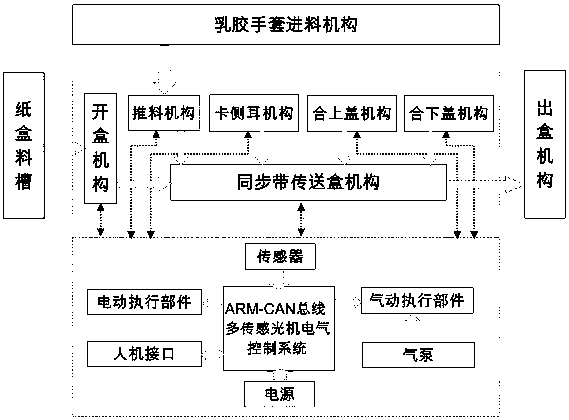

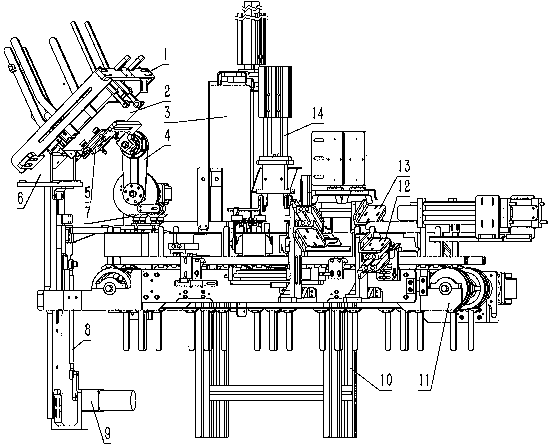

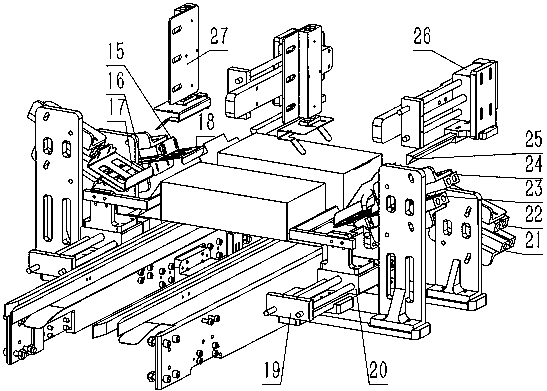

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a latex glove carton automatic packaging robot includes a box opening mechanism, a material feeding and pushing mechanism, a card side ear mechanism, a lid closing mechanism, a lower lid closing mechanism, a synchronous belt conveyor box mechanism and a box output mechanism. The entire packaging process includes the processes of opening the box, pushing the material, locking the side ears, closing the cover, closing the lower cover, etc. according to the sequence of actions. The packaging robot is realized through multiple embedded ARM-CAN bus multi-sensor optical-mechanical electrical control systems: the main controller, controller 1, controller 2, controller 3, and controller 4 communicate with each other through the CAN bus. The following takes the double-safety plug-in carton with a swing cover as the packaging body, and takes the packaging process of a certain number of disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com