All-steel radial tyre bead chafer, and preparation method thereof

A radial and tire technology, which is applied in the field of preparation of all-steel radial tire mouth guard rubber, can solve the problem of excessive heat generation of the rubber compound, reduce heat generation, improve aging resistance, and improve anti-vulcanization reversion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

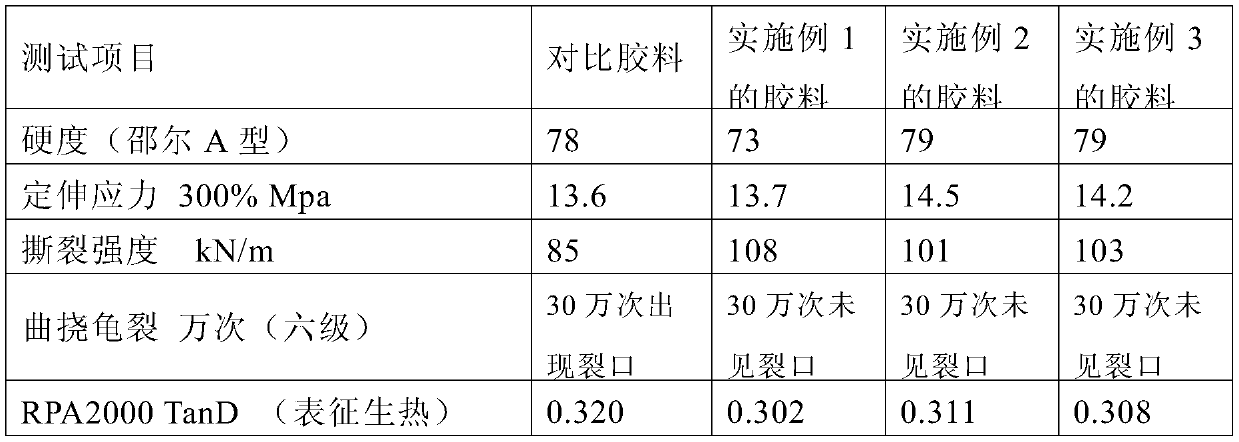

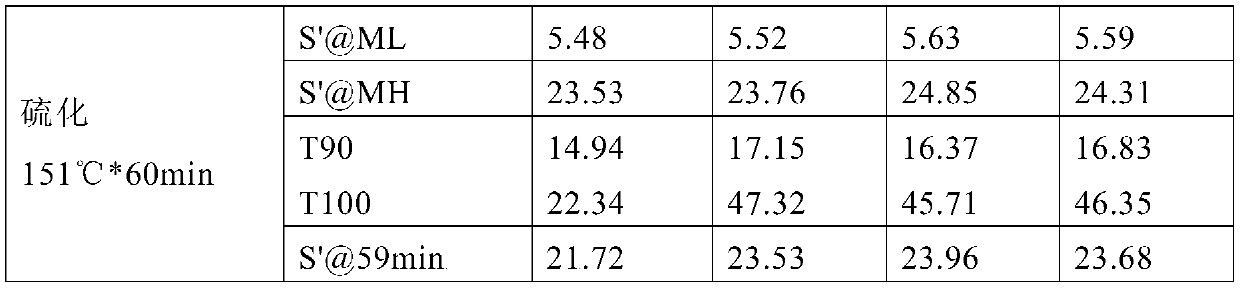

Examples

Embodiment 1

[0025] A preparation method of all-steel radial tire rim protection rubber, which adopts the following process steps, and the component ratio is calculated in parts by weight:

[0026] (1) One-stage mixing: 50 parts of natural rubber, 20 parts of high-cis-butadiene rubber, 10 parts of low-cis-butadiene rubber, 30 parts of carbon black N330, 3 parts of zinc oxide, pre-dispersed modified aramid Put 1 part of short fiber and 2 parts of 203 resin into BB430 type internal mixer for mastication, the pressure of the top bolt is 5.5MPa, the rotor speed is 50r / min, the temperature of debinding is 160°C, and the time is 100 seconds. For rubber mixing, the parking time should not be less than 8 hours;

[0027] (2) Two-stage mixing: the obtained first-stage compound rubber, 40 parts of carbon black N330, 4 parts of stearic acid, 1 part of anti-aging agent 4020, 1 part of anti-aging agent RD, 2 parts of aromatic oil, and 2 parts of protective wax Put it into a BB430 type internal mixer fo...

Embodiment 2

[0030] A preparation method of all-steel radial tire rim protection rubber, which adopts the following process steps, and the component ratio is calculated in parts by weight:

[0031] (1) One-stage mixing: 20 parts of natural rubber, 50 parts of high-cis-butadiene rubber, 20 parts of low-cis-butadiene rubber, 25 parts of carbon black N375, 6 parts of zinc oxide, modified aramid staple fiber Put 6 parts and 5 parts of 204 resin into BB430 type internal mixer for masticating, the upper bolt pressure is 5.5MPa, the rotor speed is 50r / min, the glue discharge temperature is 160℃, and the time is 100 seconds to obtain a mixed rubber , the parking time is not less than 8 hours;

[0032] (2) Two-stage mixing: the obtained first-stage mixed rubber, 55 parts of carbon black N375, 3 parts of stearic acid, 1 part of anti-aging agent 4020, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent 3100, aromatic oil Put 6 parts and 1 part of protective wax into a BB430 type internal mix...

Embodiment 3

[0035] A preparation method of all-steel radial tire rim protection rubber, which adopts the following process steps, and the component ratio is calculated in parts by weight:

[0036] (1) One-stage mixing: 30 parts of natural rubber, 40 parts of high-cis-butadiene rubber, 30 parts of low-cis-butadiene rubber, 25 parts of carbon black N375, 4 parts of zinc oxide, modified aramid staple fiber Put 4 parts and 3 parts of KORESIN resin into BB430 type internal mixer for mastication, the pressure of the top bolt is 5.5MPa, the rotor speed is 50r / min, the discharge temperature is 160°C, and the time is 100 seconds to obtain a mixed rubber , the parking time is not less than 8 hours;

[0037] (2) Two-stage mixing: the obtained first-stage mixed rubber, 30 parts of carbon black N375, 2 parts of stearic acid, 1 part of anti-aging agent 4020, 1 part of anti-aging agent RD, 1 part of anti-aging agent 3100, naphthene Put 4 parts of oil and 1.2 parts of protective wax into a BB430 type in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com