Water-based tasteless printing ink

A printing ink, water-based technology, applied in the field of water-based odorless printing ink, can solve the problems of poor leakage resistance, non-flammability, PE film pollution, etc., and achieve the effect of reasonable ink gloss, small fluidity difference, and moderate drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

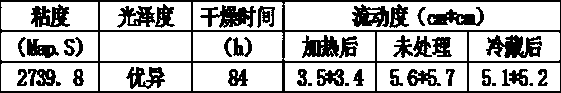

Image

Examples

Embodiment 1

[0030] A kind of water-based odorless printing ink, described ink is made from the raw material of following weight part:

[0031] 15 parts of water-soluble acrylic resin;

[0032] 5 parts of ammoniating agent;

[0033] 6 parts of absolute ethanol;

[0034] 8 parts of carbon black paste;

[0035] 15 parts pure water;

[0036] 1 part of stabilizer;

[0037] 1 part adhesive remover;

[0038] Anti-drying agent 2 parts.

[0039]

Embodiment 2

[0041] A kind of water-based odorless printing ink, described ink is made from the raw material of following weight part:

[0042] 20 parts of water-soluble acrylic resin;

[0043] 6.5 parts of ammoniating agent;

[0044] 7.5 parts of absolute ethanol;

[0045] 10 parts of carbon black slurry;

[0046] 20 parts of pure water;

[0047] 2 parts of stabilizer;

[0048] 2 parts of adhesive remover;

[0049] Anti-drying agent 3 parts.

[0050]

Embodiment 3

[0052] A kind of water-based odorless printing ink, described ink is made from the raw material of following weight part:

[0053] 25 parts of water-soluble acrylic resin;

[0054] 8 parts of ammoniating agent;

[0055] 9 parts of absolute ethanol;

[0056] 12 parts of carbon black slurry;

[0057] 25 parts of pure water;

[0058] 3 parts of stabilizer;

[0059] 3 parts of adhesive remover;

[0060] Anti-drying agent 34 parts.

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com