Method and system for producing clean coal by coupling power generation in a power plant

A power plant, clean technology, used in steam generation, steam generation devices, lighting and heating equipment, etc., to simplify the production process, reduce investment, and stabilize the furnace temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

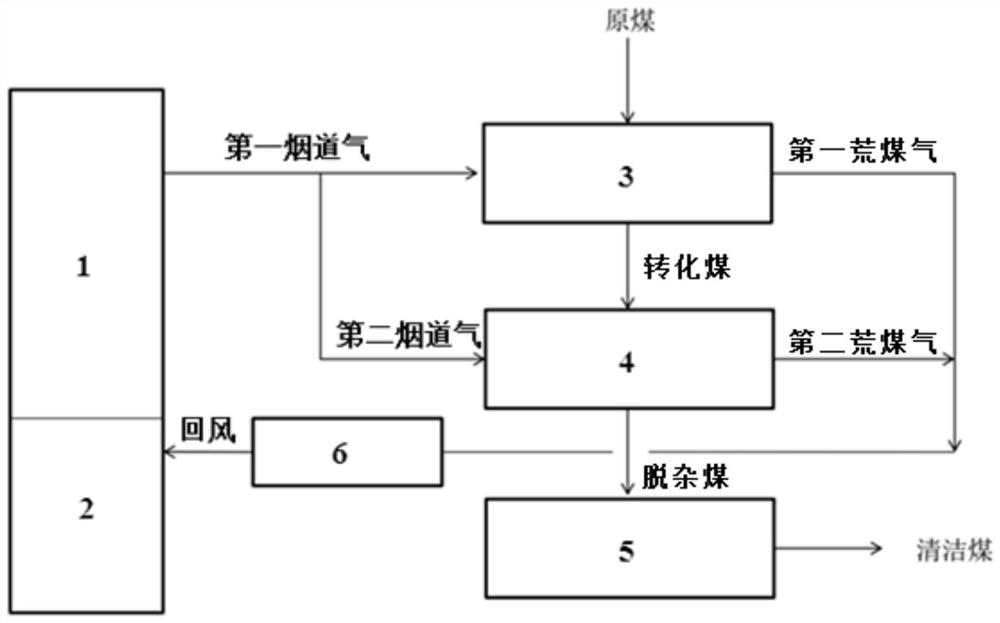

Method used

Image

Examples

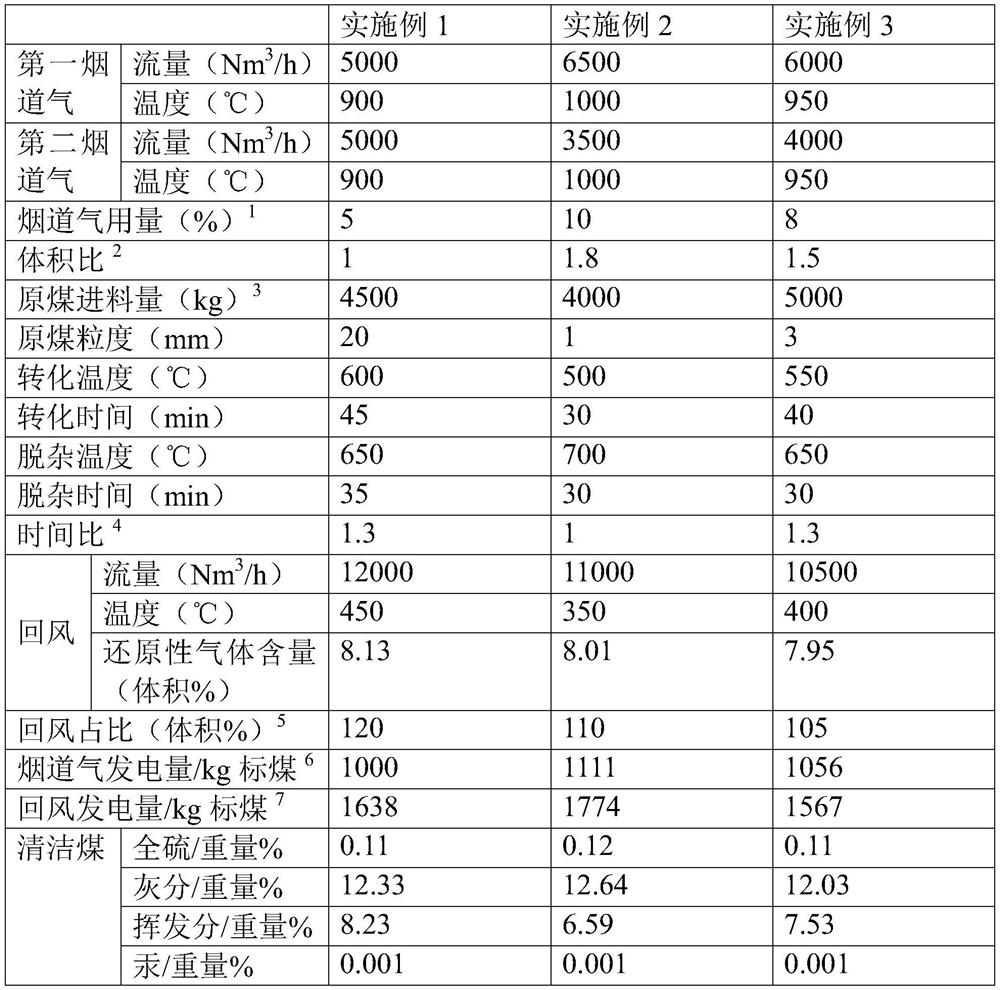

Embodiment 1

[0067] (1) put 5000Nm 3 / h of the first flue gas (900°C) and 4500kg of raw coal (lignite, particle size 20mm) are directly contacted in a countercurrent manner in the rotary kiln, and the coal conversion is carried out for 45min, and the final conversion temperature is 600°C, and the first raw coal is obtained. gas and converted coal;

[0068] (2) put 5000Nm 3 The second flue gas (900°C) per hour is in direct contact with the converted coal in a countercurrent manner in the rotary kiln, and the coal is decontaminated for 35 minutes. The final decontamination temperature is 650°C to obtain the second raw coal gas and decontaminated coal;

[0069] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0070] (4) Merge the first and second raw gas into return air (12000Nm 3 / h, temperature 450°C), and return to the burner of the power plant boiler through the induced draft device for power generation.

[0071] The total flow of the first flue gas and the second flu...

Embodiment 2

[0074] (1) Will 6500Nm 3 / h of the first flue gas (1000°C) and 4000kg of raw coal (non-caking coal, particle size of 1mm) are directly contacted in a fluidized bed in a countercurrent manner, and the coal conversion is carried out for 30 minutes, and the final conversion temperature is 500°C. The first raw gas and converted coal;

[0075] (2) 3500Nm 3 The second flue gas (1000°C) per hour is in direct contact with the converted coal in a countercurrent manner in the rotary kiln, and the coal is decontaminated for 30 minutes, and the final decontamination temperature is 700°C to obtain the second raw gas and decontaminated coal;

[0076] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0077] (4) Merge the first and second raw gas into return air (11000Nm 3 / h, temperature 350°C), and return to the burner of the power plant boiler through the induced draft device for power generation.

[0078] The total flow of the first flue gas and the second flue gas is ...

Embodiment 3

[0081] (1) Will 6000Nm 3 / h of the first flue gas (950°C) and 5000kg of raw coal (long-flame coal, particle size 3mm) are directly contacted in a countercurrent manner in the moving bed, and the coal conversion is carried out for 40 minutes, and the final conversion temperature is 550°C, and the first - raw gas and converted coal;

[0082] (2) 4000Nm 3The second flue gas (950°C) per hour is in direct contact with the converted coal in a countercurrent manner in the rotary kiln, and the coal is decontaminated for 30 minutes, and the final decontamination temperature is 650°C to obtain the second raw coal gas and decontaminated coal;

[0083] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0084] (4) Put the first and second raw gas as figure 2 As shown, each returns to the boiler and burner of the power plant through the induced air device for power generation, and the total return air flow is 10500Nm 3 / h, temperature 400°C.

[0085] The total flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com