A hydrogenation reaction system

A hydrogenation reaction and reaction unit technology, applied in the field of oil refining and chemical industry, can solve the problems of inability to directly integrate the circulating hydrogen purification process and occupy a large area, and achieve the effects of reducing process complexity, improving utilization efficiency, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

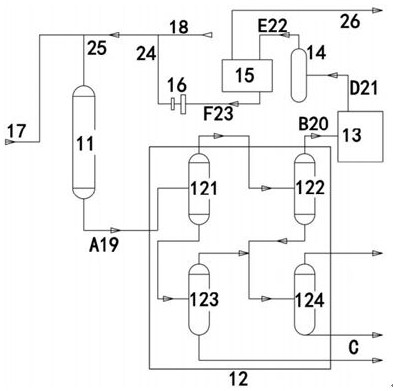

[0051] A 500,000-ton / year hydrocracking plant uses VGO as the main raw material to produce middle distillates (jet fuel + diesel), and the operating pressure of the unit is 10MPa. After the modification of the device, an adsorption separation unit is added, such as figure 1 Hydrogenation system shown.

[0052] Before the transformation, the molar concentration of new hydrogen in the original device was 95%, the molar concentration of circulating hydrogen was 78%, and the replenishment of new hydrogen was 20,000Nm 3 / h, circulating hydrogen 50000Nm 3 / h, the amount of hydrogen-containing gas discharged from the high-pressure separator is 1200Nm 3 / h.

[0053] The hydrogen circulation system of the device is reformed by adopting the present invention. After the reformation, the purity of the hydrogen circulation can be increased from 78% to 85%-95% through the adsorption separation unit. The hydrogen recovery rate of the adsorption separation unit is 95%-85%. Taking hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com