Gas-liquid separation process for hydrogenation reaction products

A technology of gas-liquid separation and reactants, which is applied in the gas-liquid separation process of hydrogenation reaction products and the gas-liquid separation process field of high-pressure hydrogenation reaction devices, can solve the problems of increasing the solubility of hydrogen, improve utilization efficiency, and reduce the cost of enterprises. Hydrogen cost, effect of demand reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Taking a certain hydrocracking as an example, the plant scale is 2 million tons per year, the raw materials are straight-run wax oil and coker wax oil, and the production plan is a high-yield jet fuel once-through process.

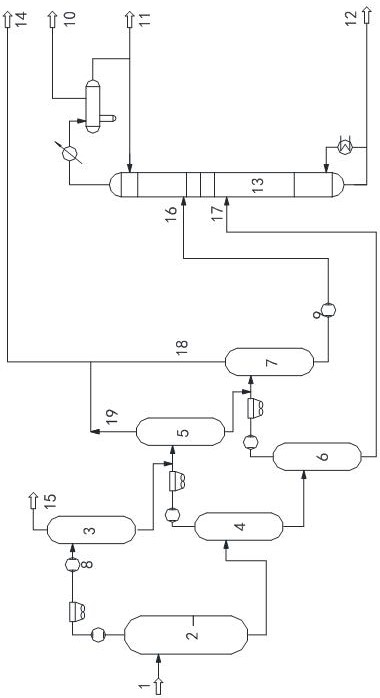

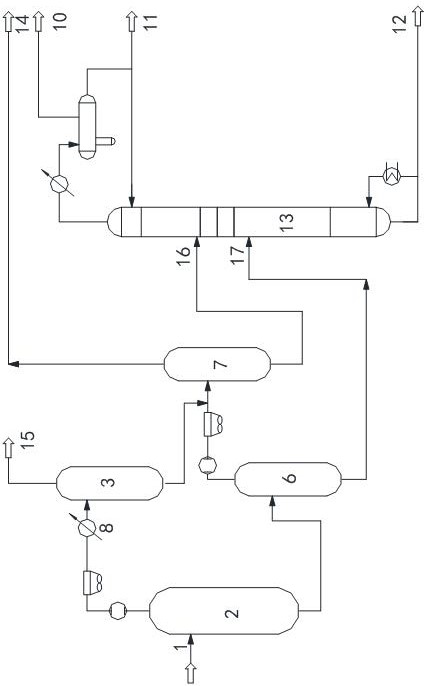

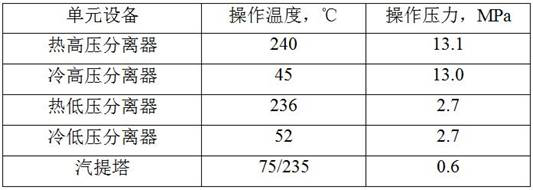

[0052] The gas-liquid separation of the reaction product adopts the invention of this technology, and the specific process is as follows figure 1 shown. After heat exchange, the hydrogenation reaction product enters the hot high-pressure separator for gas-liquid separation, and the gas phase of the hot high-pressure separator (referred to as hot high-separation gas) undergoes heat exchange and cooling, and the gas phase of the medium-pressure separator (referred to as middle separation gas) The cold mid-partition gas enters the cold high-pressure separator after being further cooled by the hot high-fraction gas phase cooler. The gas phase of the cold high-pressure separator enters the circulating hydrogen desulfurization and compression system as c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com