Preparation process of fuel element pellets for hospital neutron irradiators

A technology for hospital neutron irradiation and fuel elements, which is applied in nuclear engineering, manufacturing reactors, reactors, etc., can solve the problems of waste products, small size, and low yield, and shorten the process flow

Process, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

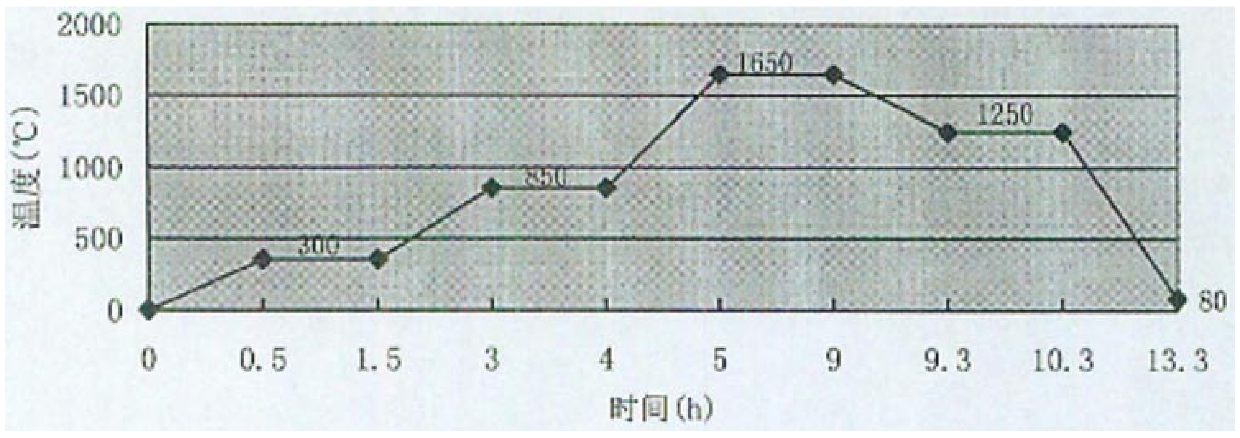

[0018] The fuel element pellet preparation process for hospital neutron irradiator of the present invention is further described in detail.

[0023]

[0025] The main purpose of the molding process is to obtain a green body with a certain size, uniform density distribution, and appearance quality that meets the requirements.

[0027] Molding pressure, pressing time and mold size can be designed and selected according to design requirements. The fuel element

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com