Regeneration method of copper molybdenum saturation resin

A resin and copper-molybdenum technology is applied in the field of regeneration of copper-molybdenum saturated resins to achieve the effects of reducing production costs, facilitating popularization and application, and uncomplicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

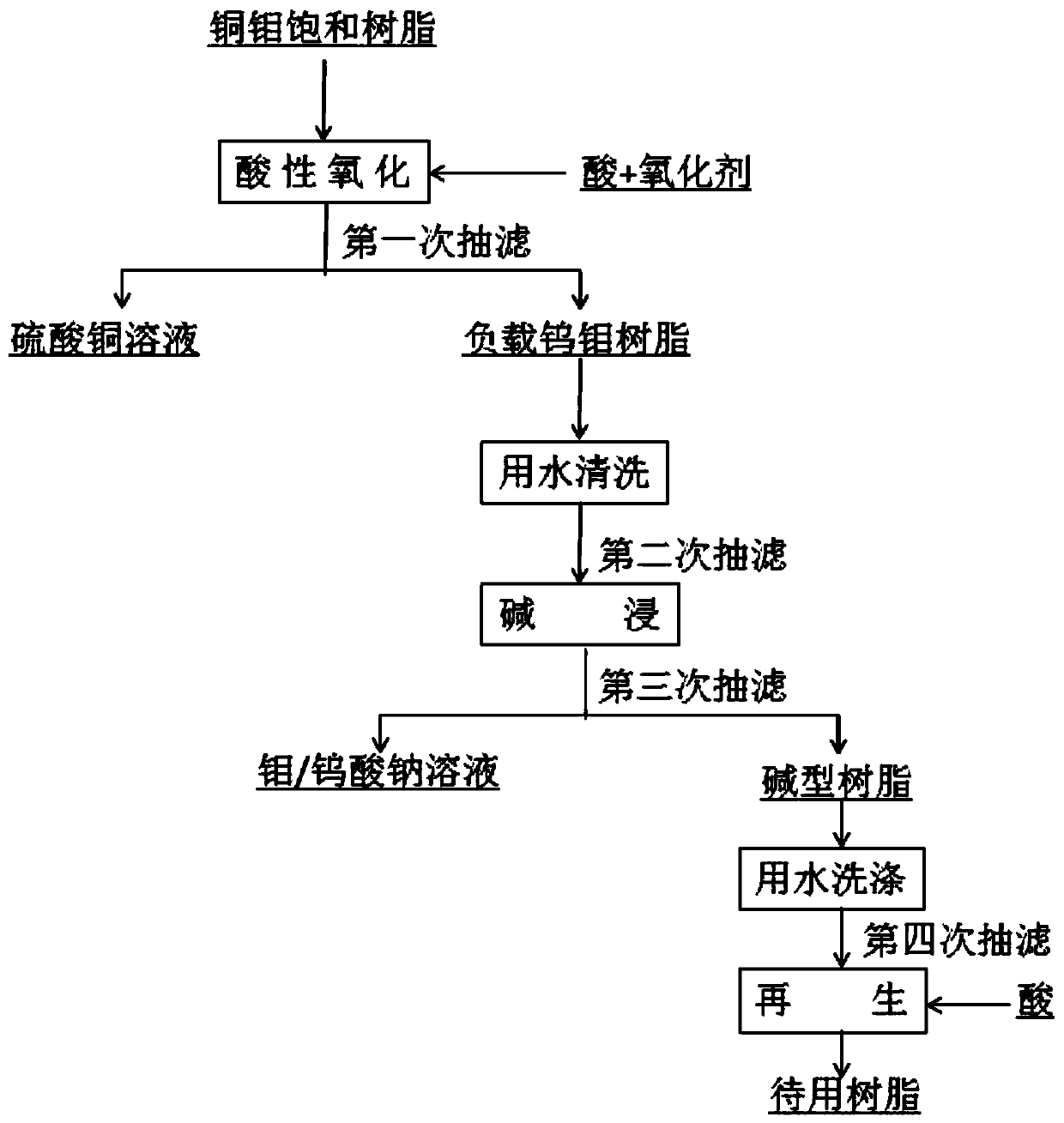

[0029] This example provides a regeneration method of copper-molybdenum saturated resin, the process is as follows figure 1 As shown, the steps include:

[0030] (1) After soaking the copper-molybdenum saturated resin with a strong acid and an oxidizing agent, carry out the first suction filtration;

[0031] (2) After washing the resin treated in step (1) with water, perform suction filtration for the second time;

[0032] (3) After alkali immersion of the resin treated in step (2), carry out suction filtration for the third time;

[0033] (4) After washing the resin treated in step (3) with water, perform suction filtration for the fourth time;

[0034] (5) Regenerate the resin treated in step (4) with a strong acid.

[0035] Wherein, the acid used is at least one of sulfuric acid, hydrochloric acid and nitric acid, and the concentration is 0.5-2 mol / L.

[0036] The oxidant is hydrogen peroxide or sodium hypochlorite with a volume concentration of 1-5 vol%.

[0037] The ...

Embodiment 2

[0042] In this example, the copper-removing D314 resin saturated by adsorption in a factory is selected. The suspended matter is washed with pure water and then suction-filtered. The dry basis rate is 43.64%. The regeneration is carried out through the following steps:

[0043] (1) 25 g of the above-mentioned D314 copper-molybdenum saturated resin was mixed with 1mol / L of H 2 SO 4 40mL and 3% (volume) H 2 o 2 Suction filtration for the first time after soaking for 20 hours to obtain oxidized resin and acidic oxidation solution;

[0044] (2) washing the resin treated in step (1) with water until the pH of the washing water is 3, and performing suction filtration for the second time;

[0045] (3) Soak the resin treated in step (2) with 50mL of 2mol / L NaOH for 2.5h, then perform suction filtration for the third time;

[0046] (4) washing the resin treated in step (3) with water until the pH of the washing water is 9, and then performing suction filtration for the fourth time...

Embodiment 3

[0052] In this example, the copper-removing D201 resin saturated by adsorption in a factory is selected. The suspended matter is washed with pure water and then suction-filtered. The dry basis rate is 40.1%. The regeneration is carried out through the following steps:

[0053] (1) 25 g of the above-mentioned D201 copper-molybdenum saturated resin was mixed with 1mol / L of H 2 SO 4 40mL and 2% (volume) H 2 o 2 Suction filtration for the first time after soaking for 20 hours to obtain oxidized resin and acidic oxidation solution;

[0054] (2) washing the resin treated in step (1) with water until the pH of the washing water is 3, and performing suction filtration for the second time;

[0055](3) Soak the resin treated in step (2) with 40mL 1mol / L NaOH for 2.5h, then perform suction filtration for the third time, then soak the resin with 40mL 1mol / L NaOH for 2.5h, then perform the fourth second suction filtration;

[0056] (4) washing the resin treated in step (3) with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com