Ferrite spheroidal graphite cast iron profile and preparation method thereof

A ductile iron and ferrite technology, applied in the field of ferritic ductile iron profiles and their preparation, to achieve the effects of large elongation, elimination of carbides, and roundness of graphite balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

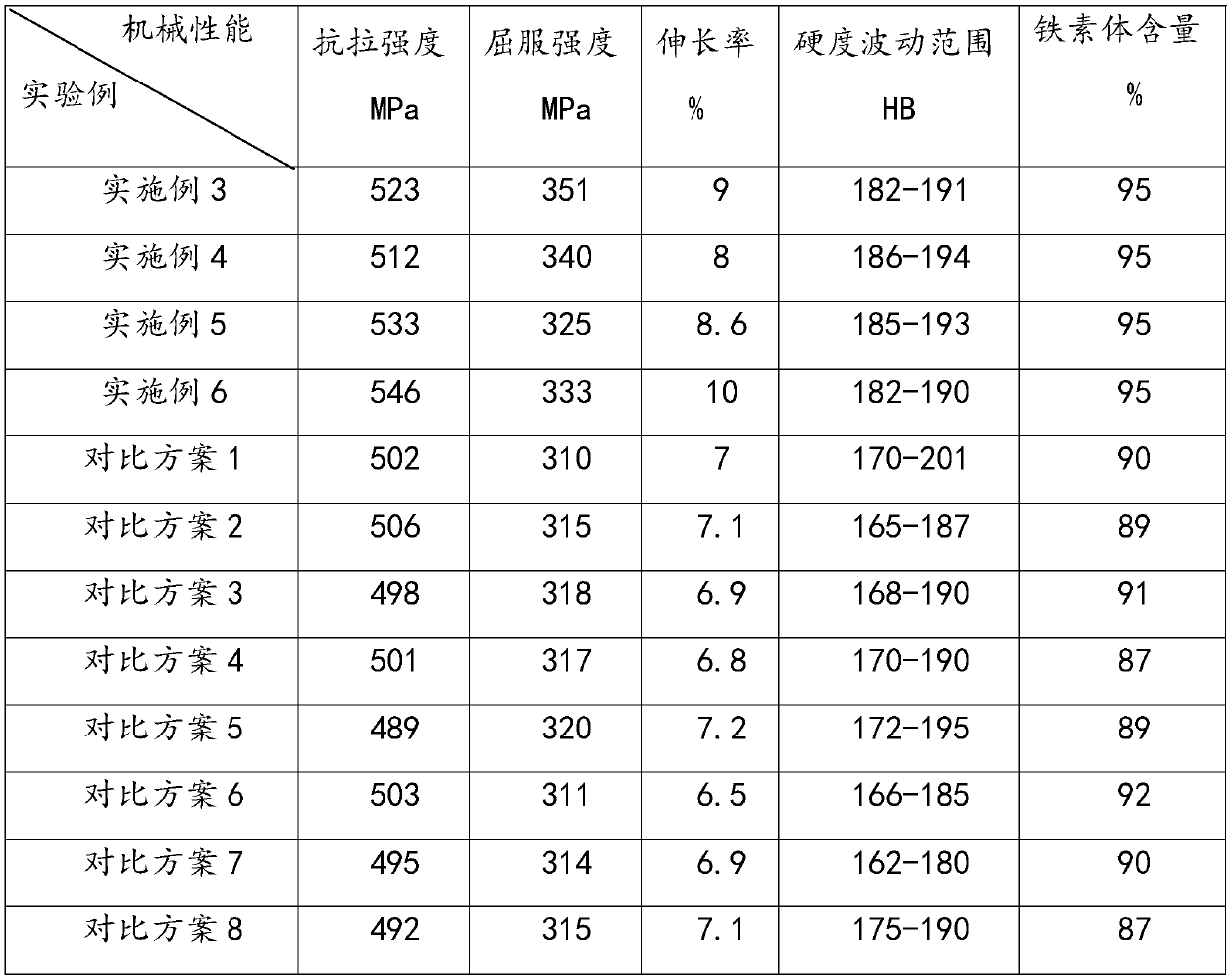

Examples

Embodiment 1

[0026] A ferritic nodular cast iron profile, which is made of QT500-7 material The profile is prepared from the following elements according to the mass percentage: carbon: 3.4%, silicon: 3.3%, manganese: 0.27%, bismuth: 0.01%, phosphorus: 0.05%, sulfur: 0.012%, and the rest is iron.

[0027] The QT500-7 material prepared according to the above mass percentage The profiles have excellent properties and have the advantages of high strength and large elongation.

Embodiment 2

[0029] A preparation method for a ferritic ductile iron profile, specifically comprising the following steps:

[0030] (1) Furnace preparation. After the combination of water-cooled graphite crystallizer and continuous casting and drawing holding furnace is installed, use natural gas to bake the continuous casting and drawing holding furnace. The baking time is 3-5 hours. Continuous casting before production The temperature in the holding furnace for drawing is 500-600°C;

[0031] (2) Ingredients Calculate and weigh pig iron, scrap steel, furnace charge and recarburizer according to the following target values: carbon: 3.4%-3.5%, silicon: 2.1%-2.2%, manganese: 0.22%-0.32%;

[0032] (3) Smelting, using medium-frequency induction furnace for smelting, put the weighed pig iron, scrap steel, returned materials and recarburizer into medium-frequency induction furnace for smelting, the molten iron is raised to between 1500-1550°C, after overheating is completed, transfer to continuo...

Embodiment 3

[0038] A method for preparing a ferritic ductile iron profile, specifically comprising the following steps:

[0039] (1) Furnace preparation, after the combination of the water-cooled graphite crystallizer and the holding furnace for continuous casting and drawing is installed, use natural gas to bake the holding furnace for continuous casting and drawing, the baking time is 4 hours, and the continuous casting and drawing before production The temperature in the holding furnace is 500°C;

[0040](2) Ingredients Calculate and weigh the above metal materials according to the following target values: carbon: 3.5%, silicon: 2.15%, manganese: 0.30%;

[0041] (3) Smelting, using medium-frequency induction furnace for smelting, put the weighed pig iron, scrap steel, returned material and recarburizer into medium-frequency induction furnace for smelting, and the molten iron is raised to 1500 ° C. After the overheating is completed, transfer to continuous molten iron The holding furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com