Ultra-low-temperature friction and wear vacuum testing machine

A friction and wear, ultra-low temperature technology, applied in the direction of testing wear resistance, etc., can solve the problems of difficult realization and maintenance, data acquisition and processing of rotary seals, no vacuum ultra-low temperature friction, etc., and achieves simple structure, stable operation and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

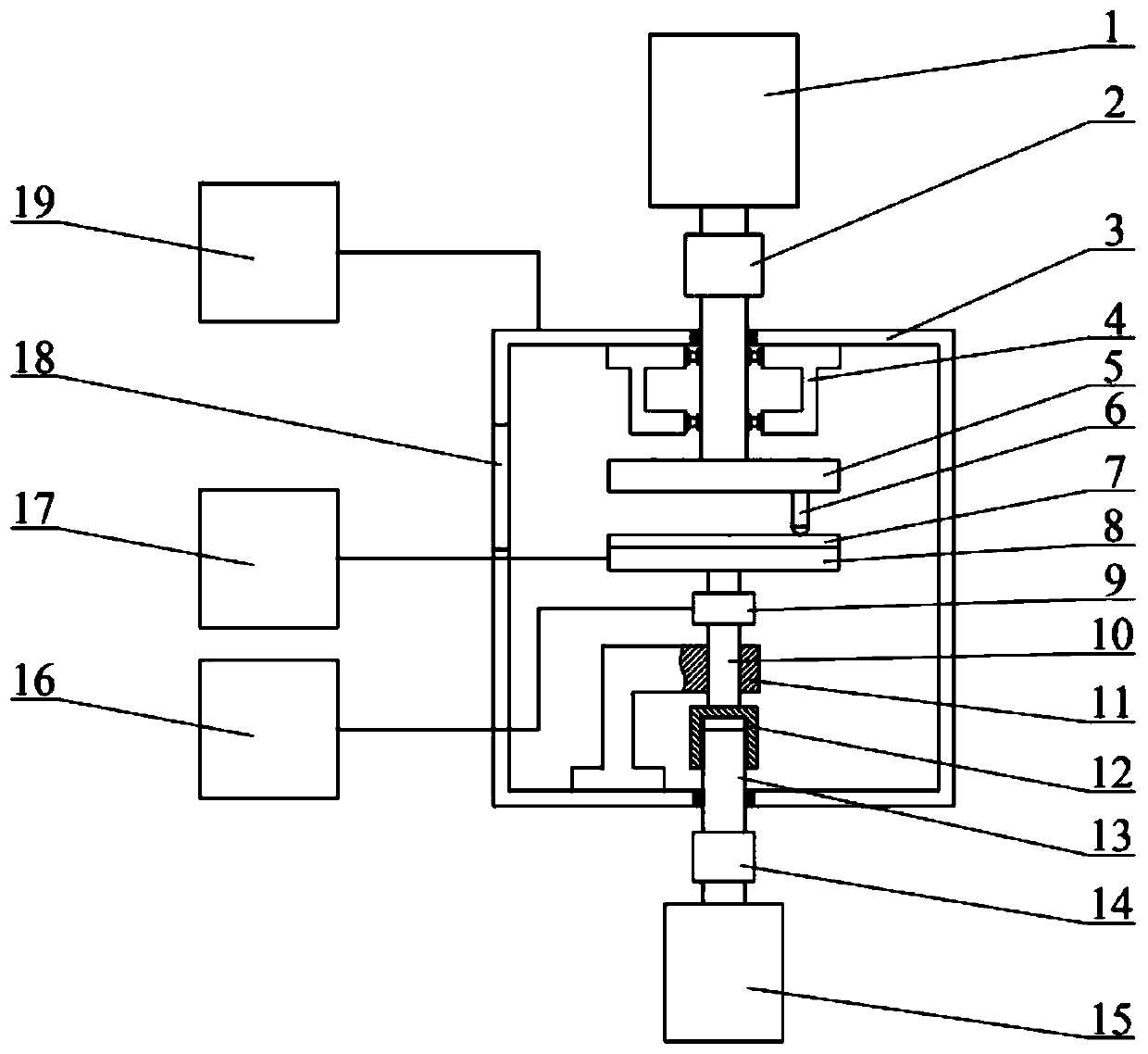

[0014] as attached figure 1 As shown, a vacuum test machine for ultra-low temperature friction and wear includes a frequency conversion motor 1, a first coupling 2, a vacuum box 3, a base 4, a rotary disc 5, an eccentric pin 6, a sample disc 7, a workbench 8, and a three-dimensional force Sensor 9, guide rod 10, bracket 11, nut 12, lead screw 13, second coupling 14, stepper motor 15, data acquisition and processing system 16, ultra-low temperature system 17, observation window 18, vacuum system 19, etc.

[0015] An observation window 18 is arranged on the side wall of the vacuum box 3 , through which the situation in the vacuum box 3 can be observed in real time.

[0016] The base 4 is arranged on the upper inner surface of the vacuum box 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com