Microwave power sensor based on composite arched beam

A microwave power, arched beam technology, applied in the direction of electric power measurement by applying the square-law characteristics of circuit components, can solve the problem of not being able to increase the beam length, and achieve improved overload resistance, good response characteristics, and stable repeated work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

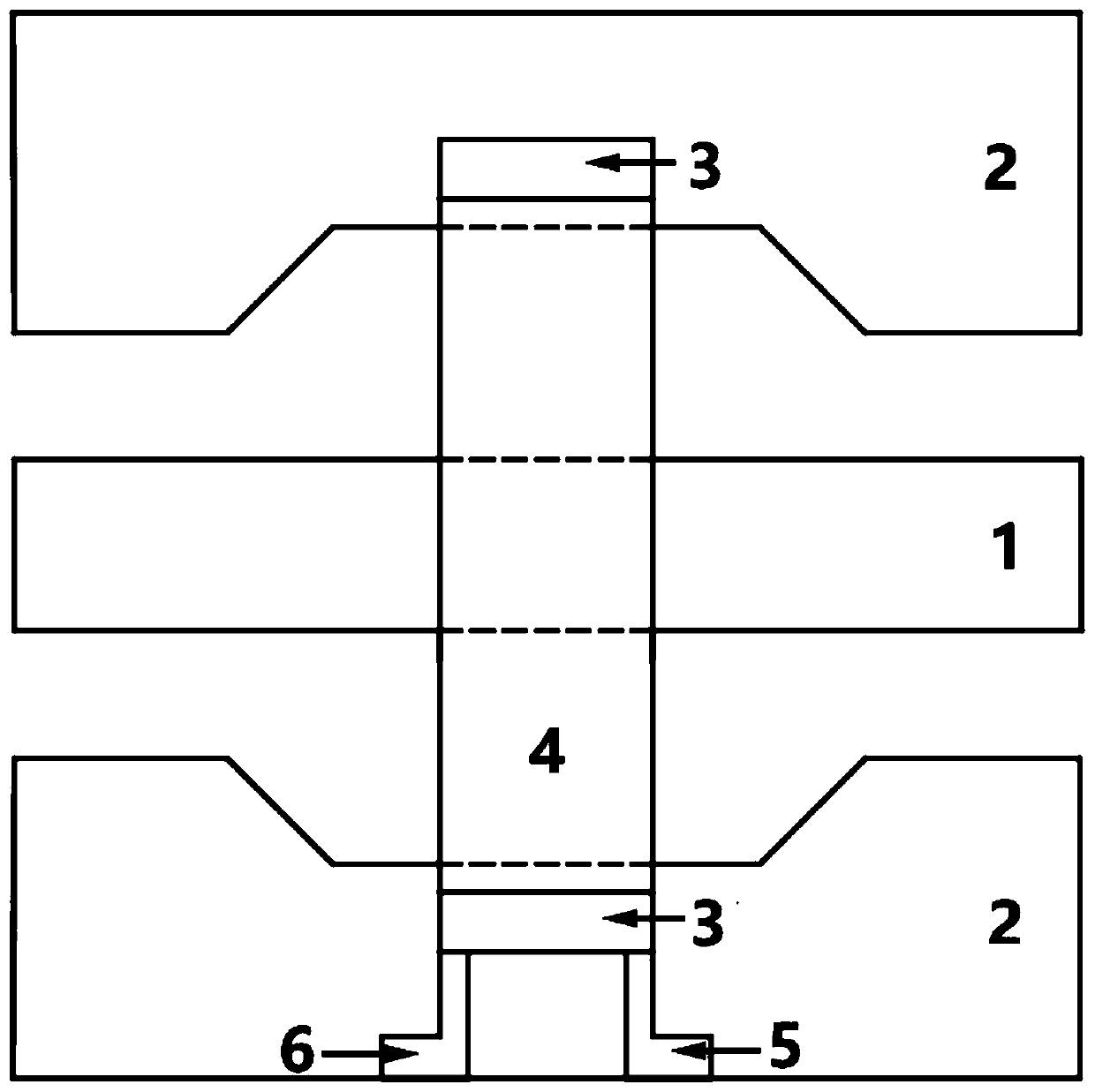

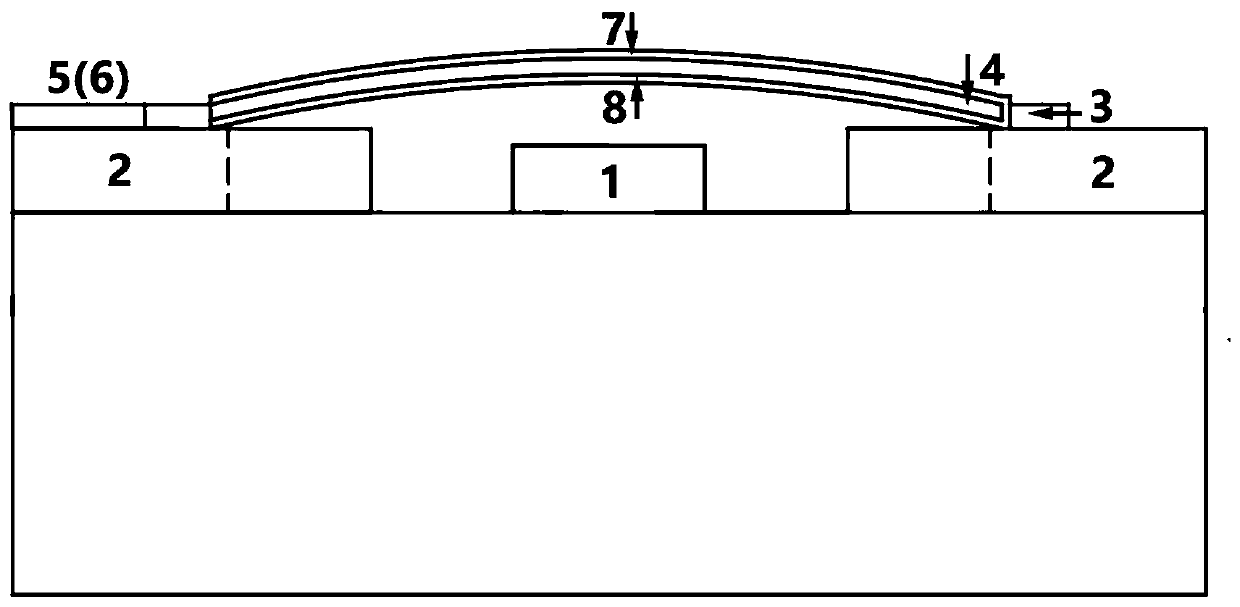

[0029] Such as Figure 1-2As shown, the microwave power sensor based on the composite arched beam in this embodiment consists of a substrate, a coplanar waveguide transmission line 1, a ground wire 2, an anchor region 3, a first output port 5, a second output port 6, and a composite arched beam Composition: a coplanar waveguide transmission line 1 is arranged in the middle of the substrate and ground wires 2 are arranged on both sides of the substrate, the composite arched beam is fixed on the ground wire 2 through the anchor area, and the coplanar waveguide transmission line 1 is arranged under the composite arched beam; The composite arched beam is composed of an elastic material 4 made of weakly doped single crystal silicon or single crystal germanium in the middle and a graphene film with a width of 50 μm and a thickness of 3 μm wrapped up and down. The upper layer of graphene film 7 and the lower layer of graphene film One side of 8 is connected by anchor region 3, two ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com