Quantum dot light emitting layer and preparation method and application thereof

A quantum dot luminescence and quantum dot technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. and unsatisfactory stability, to achieve stable luminous performance, low cost, and stable structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

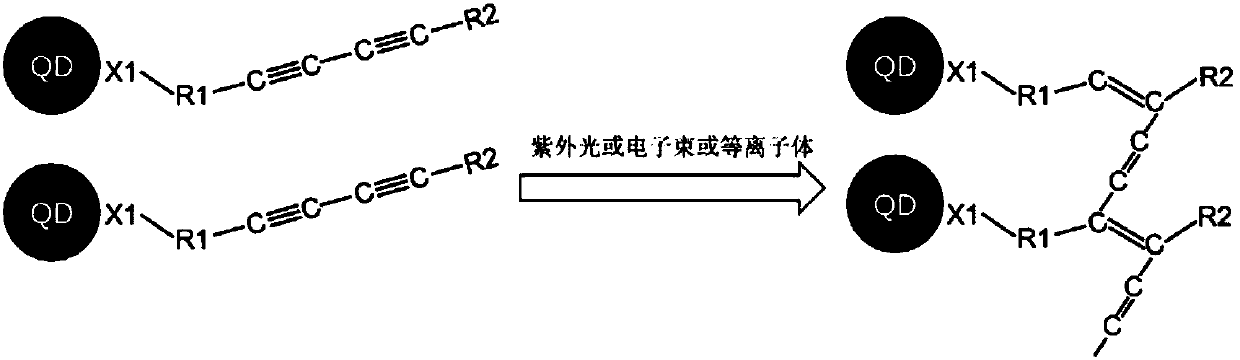

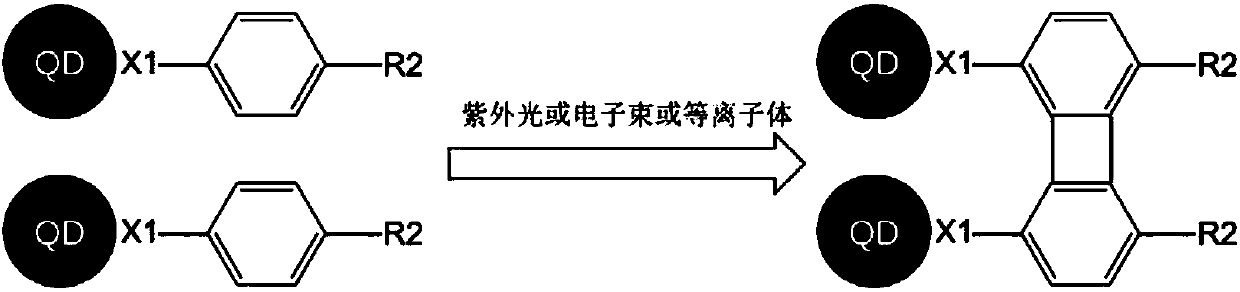

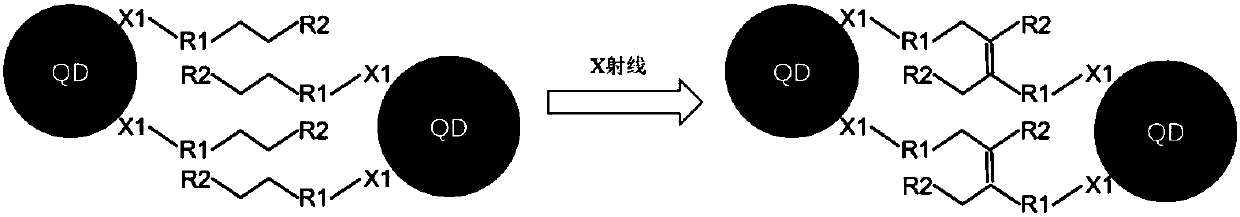

[0038] On the basis of the quantum dot light-emitting layer described above, the embodiment of the present invention also provides a preparation method of the quantum dot light-emitting layer. The technological process of the preparation method of the quantum dot luminescent layer is as follows: Figure 4 As shown, it includes the following steps:

[0039] S01: Provide a quantum dot prefabricated film with organic ligands bound to the surface of the quantum dot;

[0040] S02: Perform cross-linking treatment on the quantum dot prefabricated film.

[0041] Specifically, the quantum dot prefabricated film in the step S01 is prepared and obtained according to the following two methods:

[0042] In the first method, the quantum dots bound with the initial ligand are first mixed with the organic ligand solution for ligand replacement, so that the quantum dots bind the organic ligands, and then the quantum dots bound with the organic ligands The quantum dot prefabricated film is fir...

Embodiment 1

[0081] This embodiment provides a quantum dot light-emitting diode and a preparation method thereof. The structure of the quantum dot light emitting diode is: ITO glass / PEDOT / TFB / CdSe quantum dot light emitting layer / ZnO / Al. The CdSe quantum dot is combined with a 3,5-octadiyn-1-hydroxyl-8-thiol ligand, and the ligand is cross-linked.

[0082] The quantum dot light-emitting diode of this embodiment is prepared according to the following method:

[0083] S11. Add 3,5-octadiyne-1-hydroxyl-8-thiol to the CdSe quantum dot solution for ligand exchange to obtain 3,5-octadiynyl-1-hydroxyl-8-thiol bound to the surface The CdSe quantum dot solution, after cleaning, drying and other post-treatments, obtains CdSe quantum dots with 3,5-octadiyne-1-hydroxyl-8-thiol on the surface, and then disperses them in chloroform to prepare quantum dots solution;

[0084] S12. Printing the PEDOT hole injection layer and the TFB hole transport layer sequentially on the ITO anode;

[0085] S13. Prin...

Embodiment 2

[0088]This embodiment provides a quantum dot light-emitting diode and a preparation method thereof. The structure of the quantum dot light emitting diode is: ITO glass / PEDOT / TFB / CdSe quantum dot light emitting layer / ZnO / Al. The CdSe quantum dots are combined with mercaptobenzoic acid ligands, and the ligands are cross-linked.

[0089] The quantum dot light-emitting diode of this embodiment is prepared according to the following method:

[0090] S11. Dispersing CdSe quantum dots in chloroform to prepare a quantum dot solution;

[0091] S12. Depositing a stacked PEDOT hole injection layer and a TFB hole transport layer on the ITO anode;

[0092] S13. Deposit the above-mentioned quantum dot solution on the TFB hole transport layer to form a CdSe quantum dot film; deposit the mercaptobenzoic acid solution on the above-mentioned quantum dot film, and perform ligand exchange to obtain CdSe quantum dots with mercaptobenzoic acid bound to the surface Prefabricated film; then using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com