Active carbon fiber dry-type mask

A technology of activated carbon fiber and activated carbon fiber cloth, which is applied in the field of dry mask patch preparation, can solve the problems of no physiotherapy effect and difficulty in having facial physiotherapy effect, and achieve the goals of accelerating healing and detumescence, accelerating wound healing, and promoting regeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

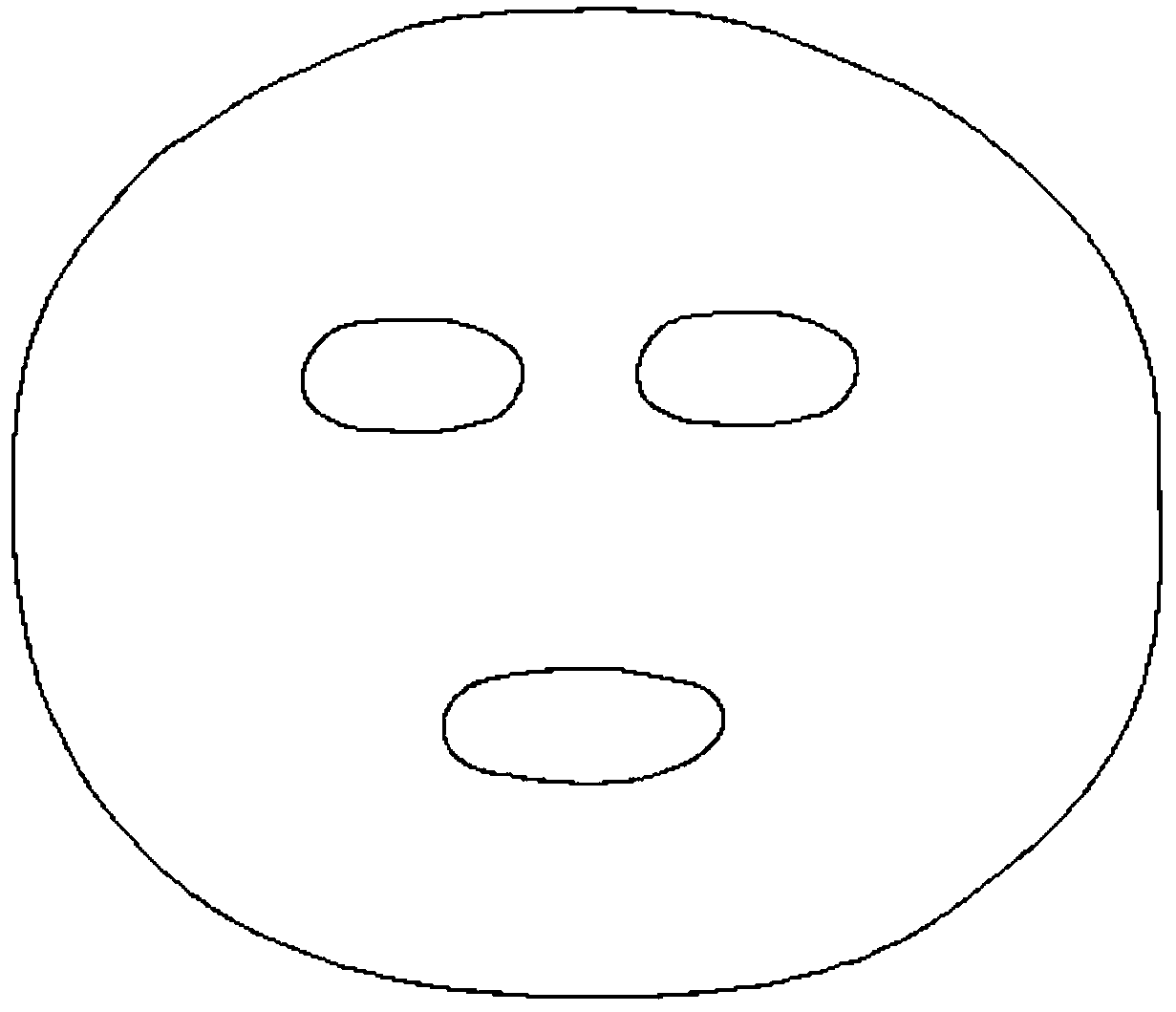

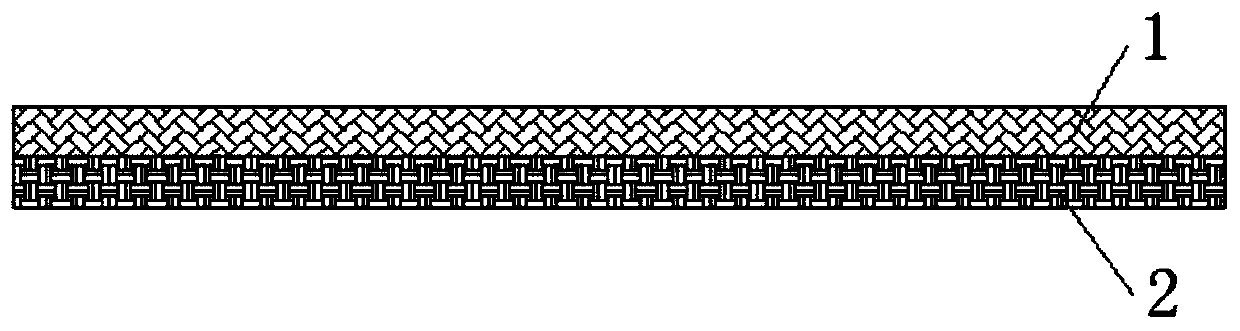

[0030] An activated carbon fiber dry-type facial mask includes two layers of activated carbon fiber cloth 1 and polyester cloth 2, and the activated carbon fiber cloth 1 and polyester cloth 2 are bonded together to form a mask sheet.

[0031] The preparation method of above-mentioned active carbon fiber dry facial mask, comprises the steps:

[0032] (1) Fiber cloth pretreatment: take ordinary acrylonitrile fiber cloth and carry out stabilization treatment under the air atmosphere condition of 200 ℃, obtain the stabilized acrylonitrile fiber raw material;

[0033] (2) Carbonization treatment: the stabilized acrylonitrile fiber raw material is placed in an inert gas atmosphere at 800°C for carbonization treatment;

[0034] (3) Activation treatment: the acrylonitrile carbon fiber material after carbonization treatment is subjected to water vapor and CO at 800°C 2 Activation treatment is carried out under mixed atmosphere conditions to obtain activated carbon fiber cloth;

[003...

Embodiment 2

[0039] An activated carbon fiber dry-type facial mask includes two layers of activated carbon fiber cloth 1 and polyester cloth 2, and the activated carbon fiber cloth 1 and polyester cloth 2 are bonded together to form a mask sheet.

[0040] The preparation method of above-mentioned active carbon fiber dry facial mask, comprises the steps:

[0041] (1) Fiber cloth pretreatment: take ordinary acrylonitrile fiber cloth and carry out stabilization treatment under the air atmosphere condition of 230° C. to obtain stabilized acrylonitrile fiber raw material;

[0042] (2) Carbonization treatment: the stabilized acrylonitrile fiber raw material is placed in an inert gas atmosphere at 1000°C for carbonization treatment;

[0043] (3) Activation treatment: the acrylonitrile carbon fiber material after carbonization treatment is subjected to water vapor and CO at 900°C 2 Activation treatment is carried out under mixed atmosphere conditions to obtain activated carbon fiber cloth;

[00...

Embodiment 3

[0048] An activated carbon fiber dry-type facial mask includes two layers of activated carbon fiber cloth 1 and polyester cloth 2, and the activated carbon fiber cloth 1 and polyester cloth 2 are bonded together to form a mask sheet.

[0049] The preparation method of above-mentioned active carbon fiber dry facial mask, comprises the steps:

[0050] (1) Fiber cloth pretreatment: take common acrylonitrile fiber cloth and carry out stabilization treatment under 270 ℃ air atmosphere condition, obtain the stabilized acrylonitrile fiber raw material;

[0051] (2) Carbonization treatment: the stabilized acrylonitrile fiber raw material is placed in an inert gas atmosphere at 1200°C for carbonization treatment;

[0052] (3) Activation treatment: the acrylonitrile carbon fiber material after carbonization treatment is subjected to water vapor and CO at 1000°C 2 Activation treatment is carried out under mixed atmosphere conditions to obtain activated carbon fiber cloth;

[0053] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com