An environmentally friendly paper shredder

A paper shredder, environmentally friendly technology, applied in punching machines, presses, presses using rotating pressure components, etc., can solve the problems of polluting the environment, wasting resources, overflowing paper scraps, etc., to increase the volume and improve the compression efficiency. , the effect of reducing the number of compressions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

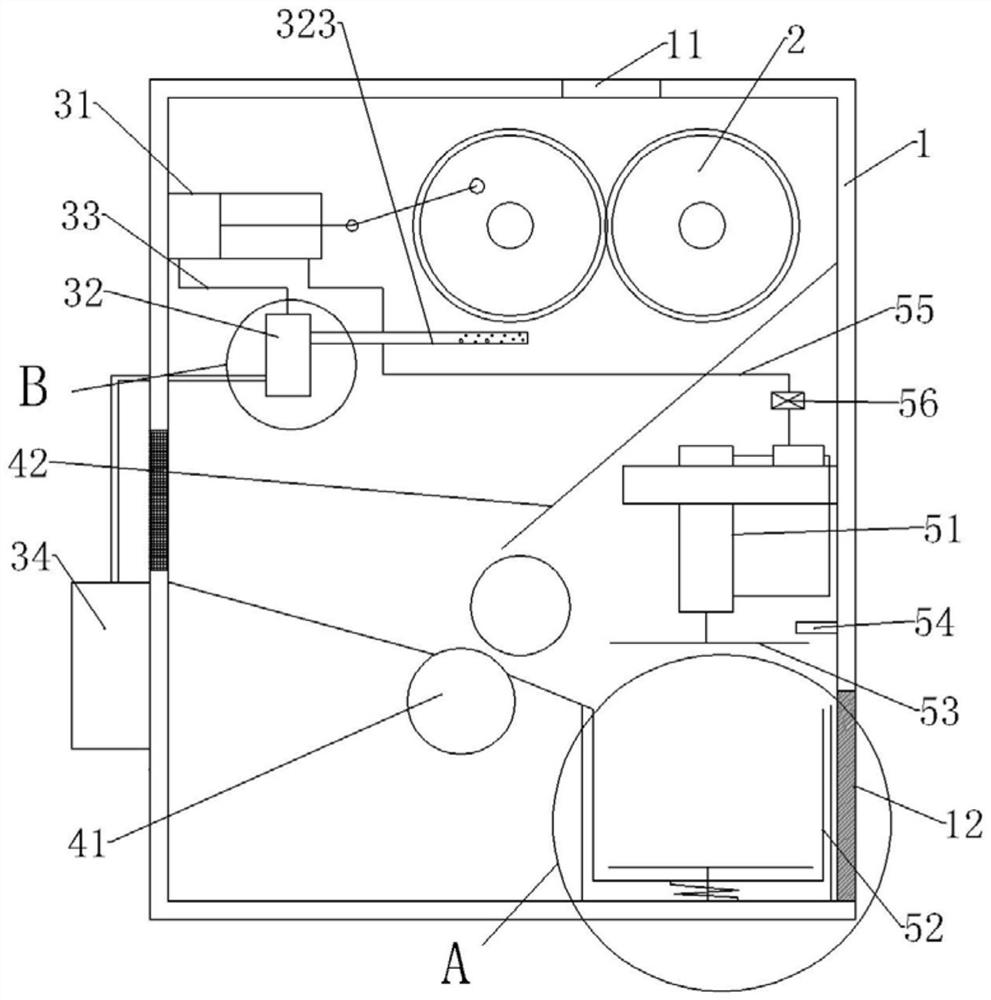

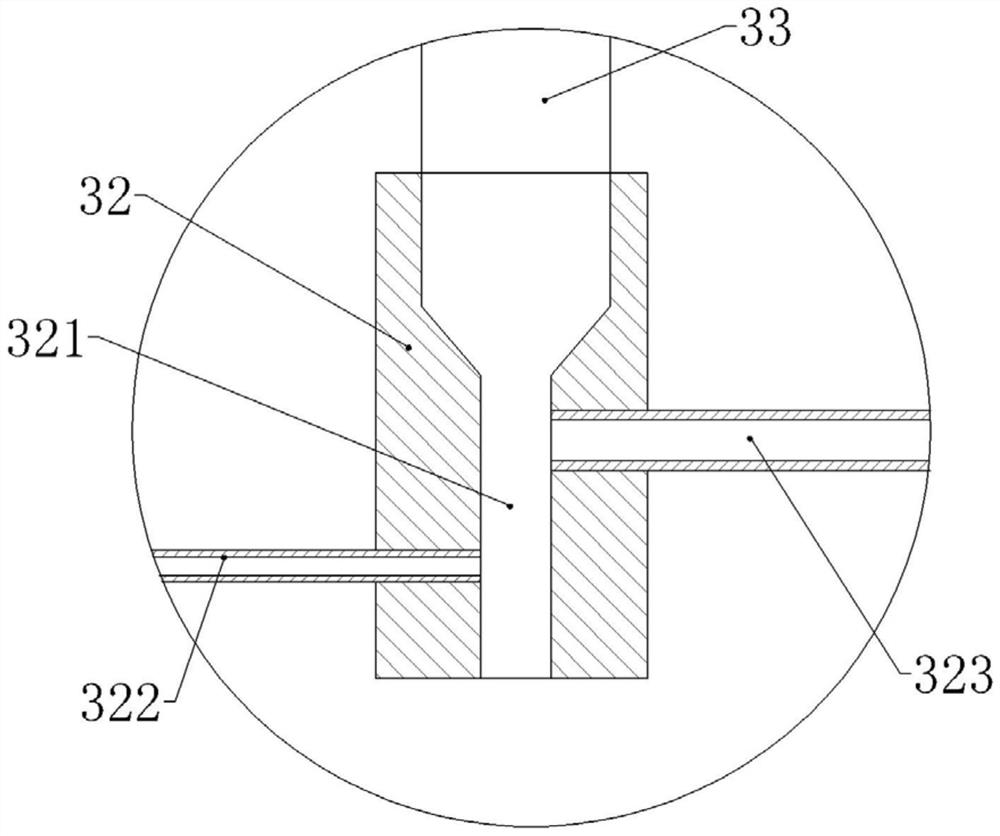

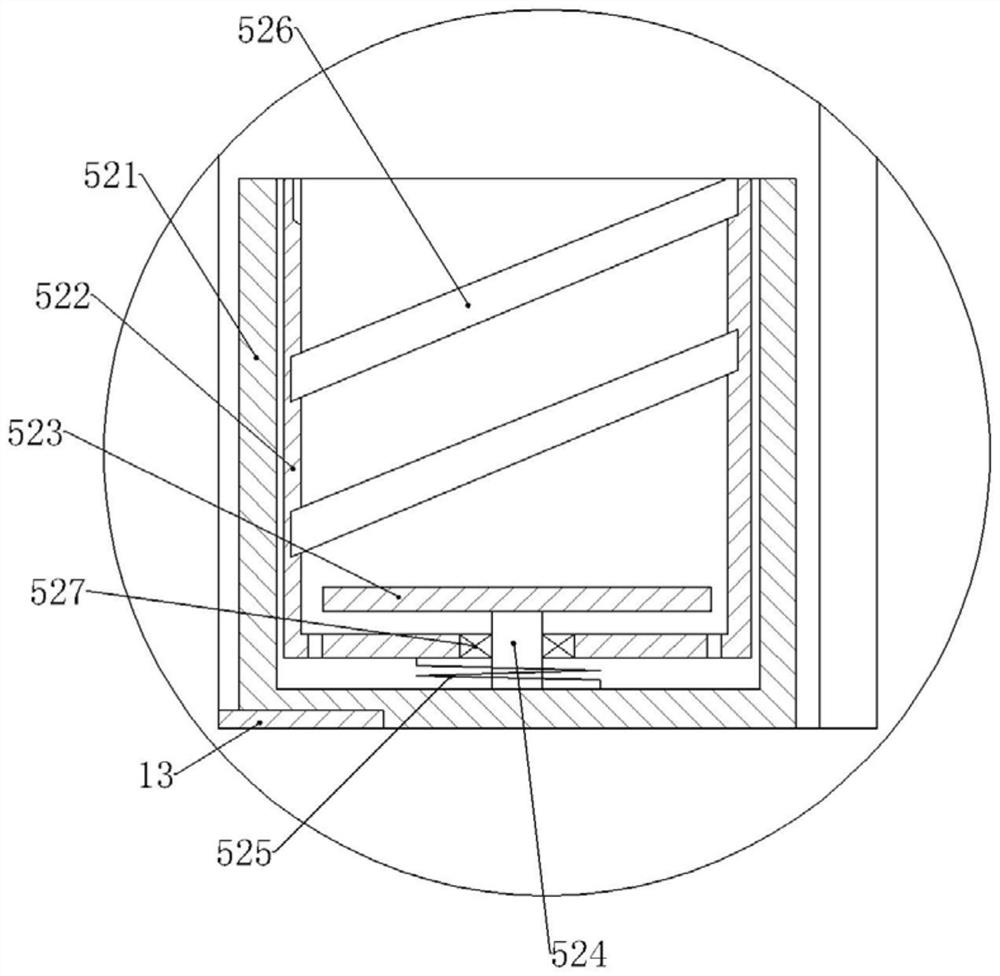

[0029] The reference signs in the drawings of the specification include: housing 1, paper inlet 11, material retrieving door 12, positioning block 13, crushing wheel 2, air cylinder 31, negative pressure pipe 32, throat 321, water suction pipe 322, dust suction Pipe 323, first air pipe 33, water tank 34, rolling wheel 41, deflector 42, cylinder 51, compression barrel 52, outer barrel 521, inner barrel 522, supporting plate 523, vertical shaft 524, torsion spring 525, spiral groove 526, One-way bearing 527, pressure plate 53, pressure switch 531, metal spool 532, compression spring 533, electromagnet 534, first switch 535, limit plate 54, second air pipe 55, overflow valve 56.

[0030] An environmentally friendly paper shredder, such as figure 1 As shown, it includes a housing 1, a shredding mechanism, a dust suction mechanism, a rolling mechanism and a compression mechanism. The top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com