Amphiphilic polymer microsphere material with uniform particle size, preparation method and application

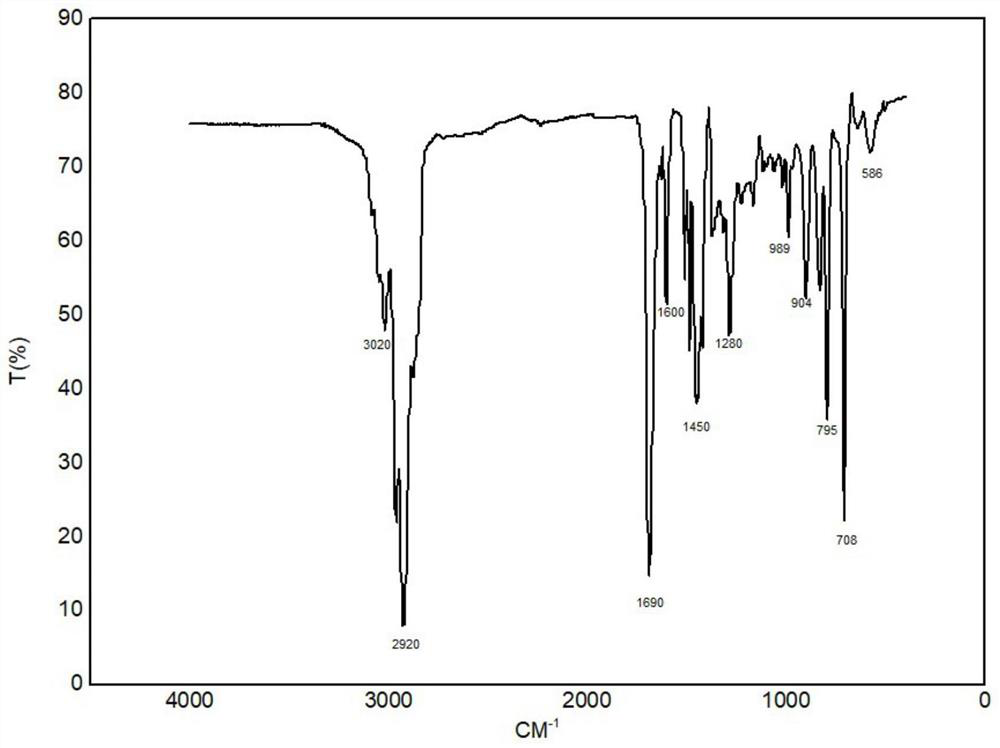

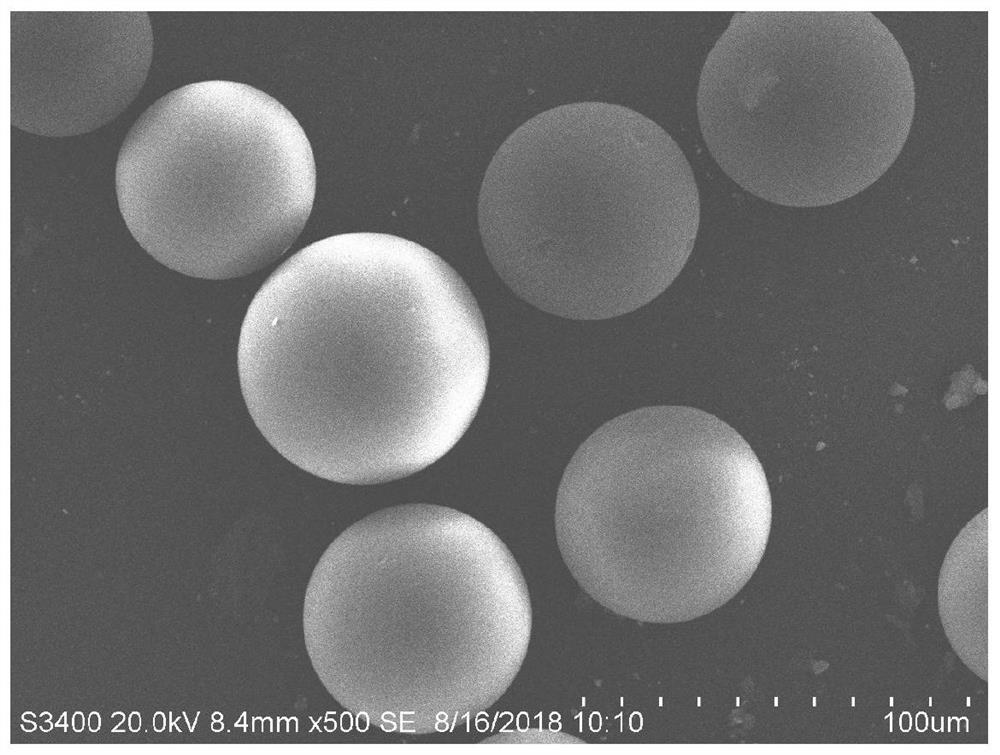

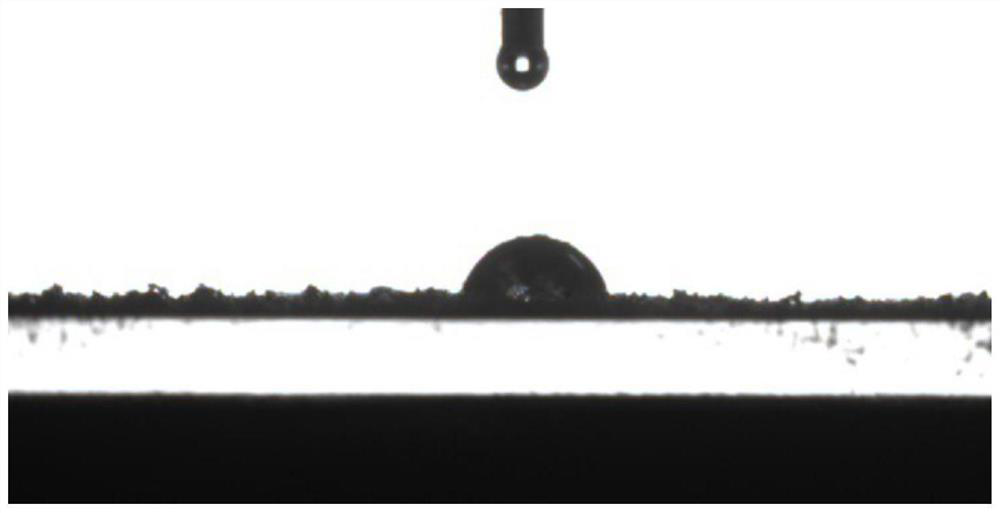

An amphiphilic polymer, particle size technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of low N-vinylpyrrolidone-divinylbenzene yield and particle size The problems of unevenness and unsatisfactory adsorption effect can achieve the effect of low cost of raw materials, good uniformity of particle size and favorable promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The steps of the amphiphilic polymer adsorption material prepared in this example are as follows:

[0041](1) Prepare the oil phase: add 2g of N-vinylpyrrolidone and 3g of divinylbenzene to 15ml of toluene solution containing 0.05g of AIBN respectively, and mix well in an ice bath to obtain the first oil phase and the second oil phase respectively. The total volume of toluene It is 74% of the total volume of the first oil phase and the second oil phase, and the total mass of the initiator AIBN accounts for 1% of the total mass of N-vinylpyrrolidone and divinylbenzene.

[0042] (2) Configure the water phase: add 0.5 g of emulsifier SDS and 0.25 g of dispersant HEC into 100 mL of aqueous solution; the amount of emulsifier is 0.49% of the total mass of the water phase, and the amount of dispersant is 0.25% of the total mass of the water phase;

[0043] (3) The water phase is divided into two parts, which are respectively recorded as the first water phase and the second wat...

Embodiment 2

[0053] Other conditions were the same as in Example 1, and the influence of different porogen dosages on the material properties was tested. The experimental results are shown in Table 2.

[0054] Table 2 The properties of materials produced by different amounts of porogen

[0055]

[0056] It can be seen from Table 2 that the amount of porogen is in the range of 10%-75% of the total volume of the oil phase. With the increase of the amount of porogen, the particle size gradually becomes smaller, and the properties of the produced materials are within the required range. However, the amount of porogen used is too low, and the particle size of the polymeric material is too large. If the amount of porogen is too high, the solution will easily become a paste and cannot be polymerized into microspheres. If the amount of porogen is too high or too low, the performance of the polymer material will be affected.

Embodiment 3

[0058] Other conditions are the same as in Example 1, and the influence of different initiator dosages on the material properties is tested, and the experimental results are shown in Table 3.

[0059] The performance of the material produced by different initiator dosages of table 3

[0060]

[0061]

[0062] As can be seen from Table 3, the amount of the initiator has little effect on the particle size within the range of 0.5%-3% of the total amount of monomers, but has a certain impact on the yield. With the reduction of the initiator content, the yield decreases. However, if the amount of the initiator is too low, the reaction cannot be initiated, and if the amount of the initiator is too high, it will cause implosion and make the polymers agglomerate together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com