Transparent PET backboard of double-layered structure and processing method thereof

A double-layer structure, transparent technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of high cost, poor weather resistance and low yield of transparent backplanes, and achieve the reduction of PET Good water absorption, wear resistance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

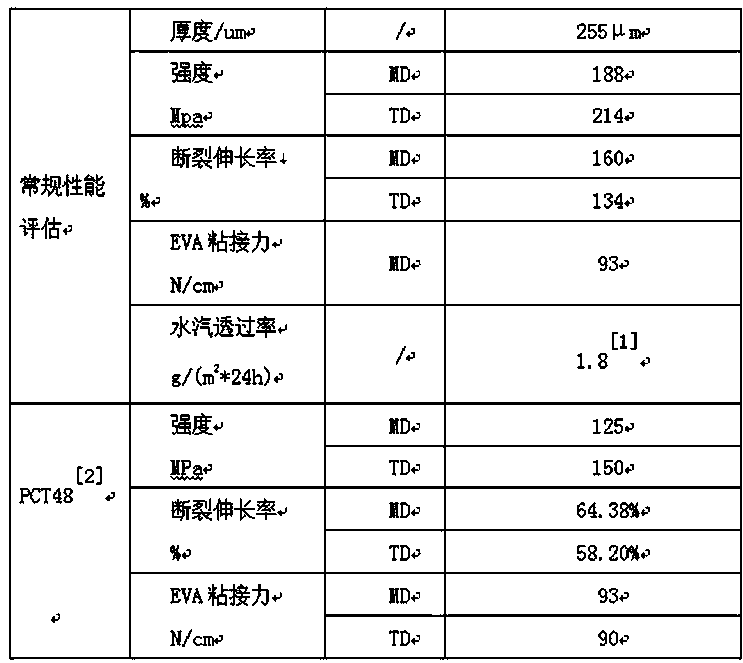

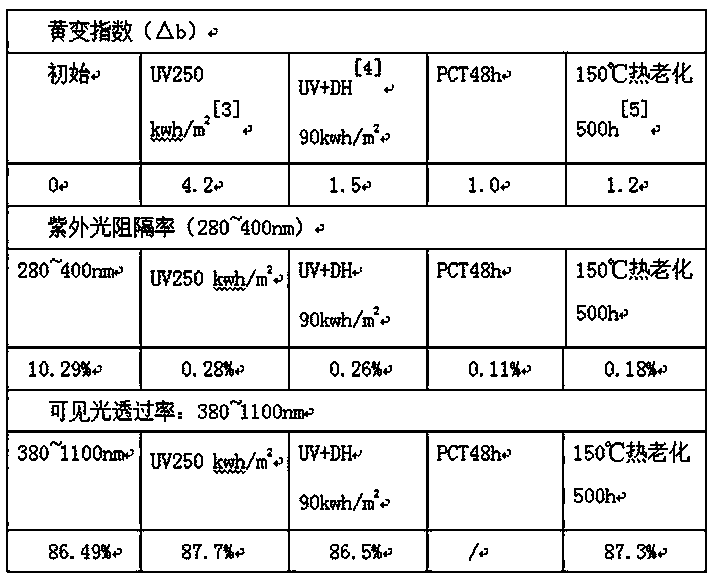

Examples

Embodiment

[0104] 1. Preparation of air layer PET particles (particle 1)

[0105] PET resin 100 parts

[0106] Compatibilizer SEBS 15 parts

[0107] Polycarbodiimide 4 parts

[0108] Primary antioxidant 1010 0.2 parts

[0109] Secondary antioxidant 168 0.4 parts

[0110] UV stabilizer UV1577 0.3 parts

[0111] UV absorber LA63P 0.5 parts

[0112] Nucleating agent NA05 0.2 parts

[0113] SiO2 0.3 parts

[0114] Lubricant AX-71 0.3 parts

[0115] White oil 0.2 parts

[0116] Wherein the intrinsic viscosity of the PET resin is 0.69, and the nucleating agent NA05 is produced by Japan Adike Company.

[0117] Dry the PET resin at 120°C for more than 8 hours, remove the water, add SEBS and white oil, mix for 3-5 minutes at a medium speed, add other powder additives, mix for 5-15 minutes at a medium speed, and pass the mixed material through the twin-screw Melt, knead, extrude and water-cool in the extruder, and then cut into pellets after drying. The temperature of each zone of the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com