Assembly type convenient-to-install composite structural slab

A combined structure and prefabricated technology, which is applied to building components, building structures, protective buildings/shelters, etc., can solve problems such as poor connection performance and difficult connection of prefabricated boards, and achieve good waterproof and reduce Connection error, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

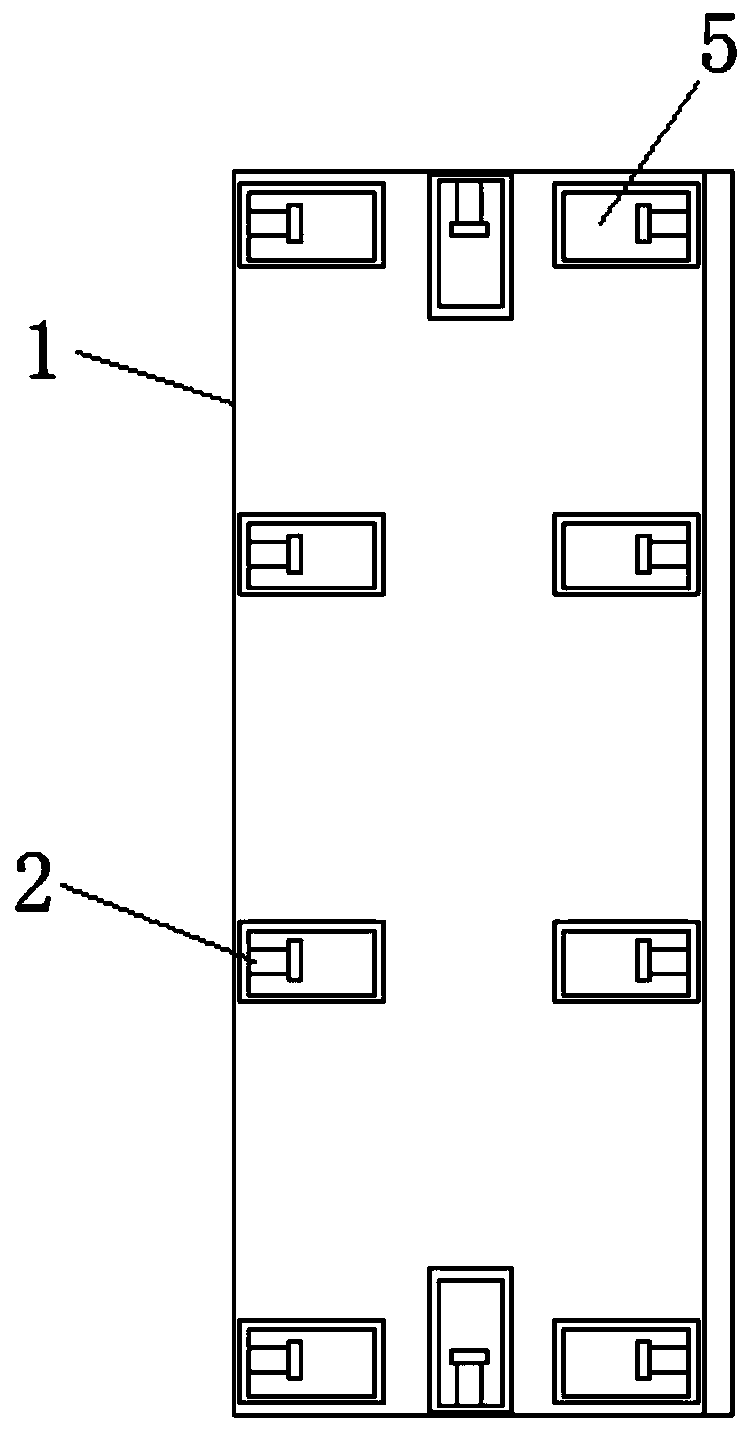

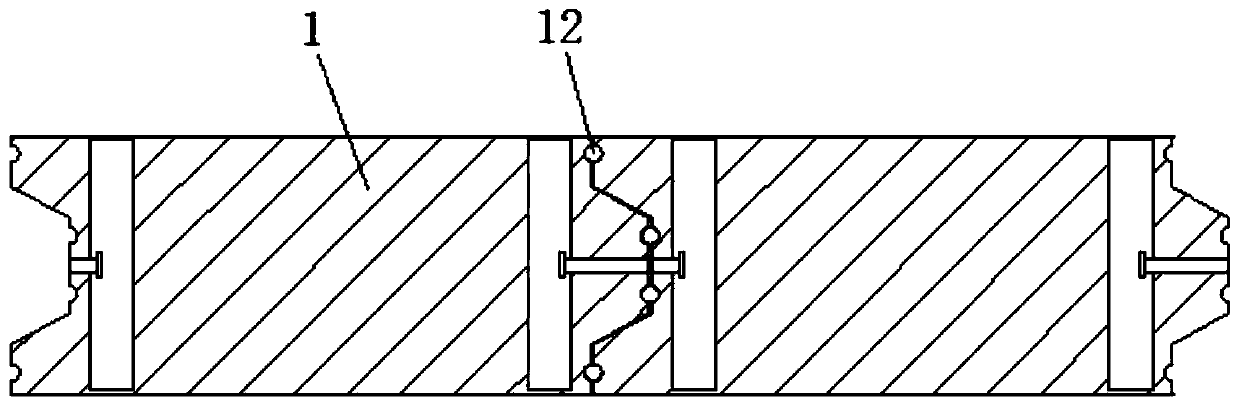

[0049] like Figure 1 to Figure 4 As shown, an assembly-type convenient installation composite structure panel includes an inner frame 1; the inner frame 1 is simulated by a cold-formed steel strip; the inside of the inner frame 1 is filled with cementitious material; the inner frame 1 The side of the inner frame 1 is provided with a number of first connection holes 2; one side of the inner frame 1 is provided with a connection protrusion 3, and the other side is provided with a connection groove 4; the connection protrusion 3 and the connection groove 4 Both are provided with a long slot 12 for putting in a waterproof rubber belt; the first connecting hole 2 is provided with a reserved hole 5 for easy installation of fasteners.

[0050] The cold-formed steel strip can be designed and shaped according to actual needs, and does not need to be manufactured according to the manufacturing form of the cast-in-place slab; after the cold-formed steel strip is formed, cement or other ...

Embodiment 2

[0058] On the basis of embodiment 1, embodiment 2 is proposed.

[0059] like Figure 7 As shown, there are several inner frames 1, and all inner frames 1 are connected in sequence; any two adjacent inner frames 1 are respectively the first inner frame 8 and the second inner frame 9; the first inner frame 8 The connecting protrusion 3 matches the connecting groove 4 of the second inner frame 9 .

[0060] The present invention discloses a structural plate combined with an inner frame 1. The setting of the connecting groove 4 and the connecting bump 3 can ensure the accurate connection between the structural plates, reduce the connection error between the two plates, and increase the distance between the two plates. The tight connection type ensures that the present invention can get good stability during use, so that the connection protrusion 3 and the connection groove 4 are closely matched without gaps, so that the structural plate has a good heat preservation effect, and It...

Embodiment 3

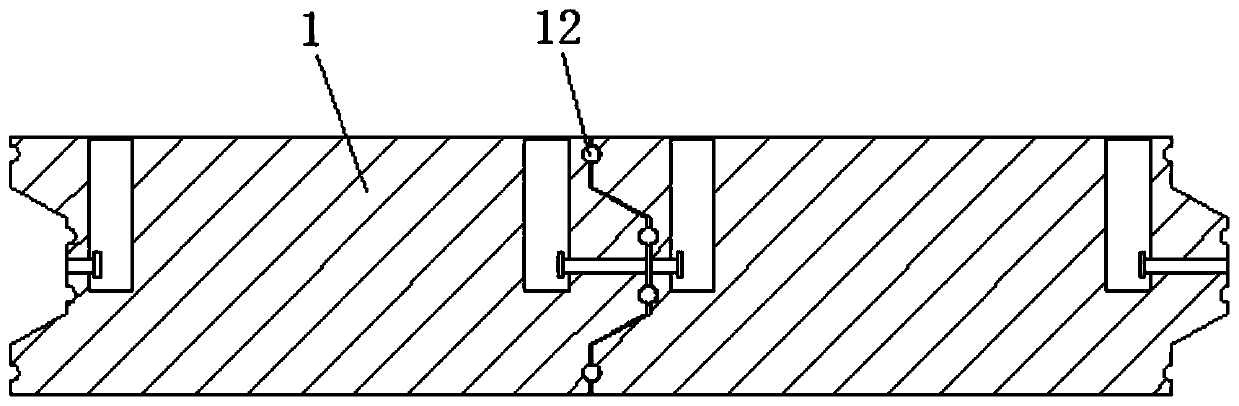

[0064] In some other examples, such as Figure 11 , and the difference from Example 2 is that the connecting groove 4 and the connecting protrusion 3 limit the left and right of the two adjacent inner frames 1. The limit of frame 1 up and down direction.

[0065] In this embodiment, the connection between the inner frames 1 can be achieved by bolts passing through the first inner frame 8 and the second inner frame 9 vertically, so that two adjacent inner frames 1 can be connected. In this embodiment, the connection groove 4 and the connection protrusion 3 can be rectangular or wedge-shaped; in some embodiments, they are arranged obliquely instead of horizontally or vertically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com