Circle-contacted coal fired boiler tube wall temperature global optimizing and debugging method

A technology for tube wall temperature and coal-fired boilers, which is applied in the control of combustion, combustion equipment, control systems, etc., can solve the problems of insufficient reheated steam temperature, overtemperature of the reheated steam tube wall, and high CO content in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

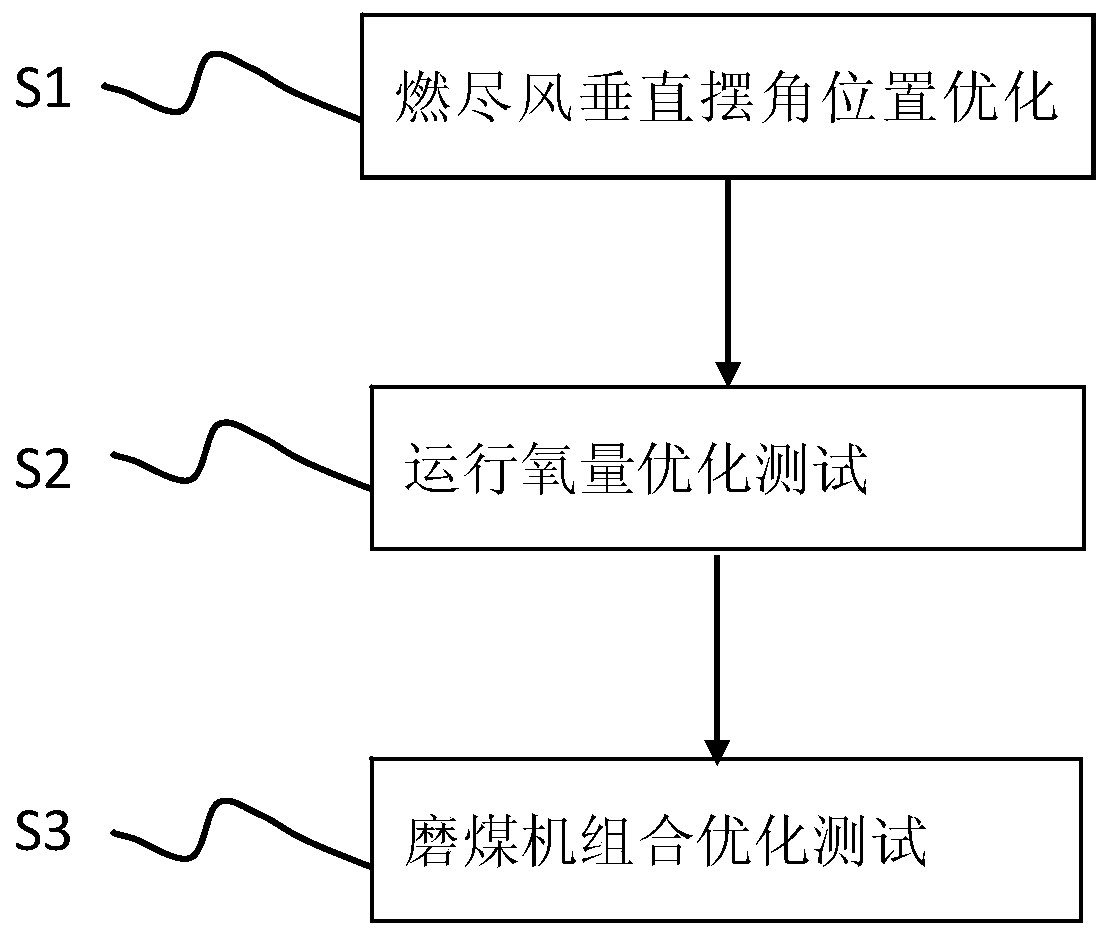

[0029] In this embodiment, the opposing coal-fired boiler unit is equipped with a safety instrumented system, hereinafter referred to as the SIS system, see the attached figure 1 As shown in the flow chart, the overall optimization and debugging method for the tube wall temperature of a tangential coal-fired boiler specifically includes the following steps:

[0030] S1. Under the high, medium and low load conditions of the unit, the differential test of the vertical swing angle position of the overburning air is carried out, and the best vertical swing angle position of the overburning air under different loads of the unit is obtained;

[0031] S2. On the basis of step S1, the operating oxygen content test is carried out for commonly used coal types, and the pipe wall temperature distribution diagrams of the heating surfaces of the water wall, panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com