A spent fuel short-stage oxidation device and method thereof

An oxidation device and spent fuel technology, applied in reactor fuel elements, chemical/physical/physicochemical mobile reactors, reducing greenhouse gases, etc., can solve the problem of inability to achieve effective separation of U3O8 powder and cladding, processing speed Slow, low processing capacity and other problems, to achieve the effect of promoting oxidation, fast reaction speed, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

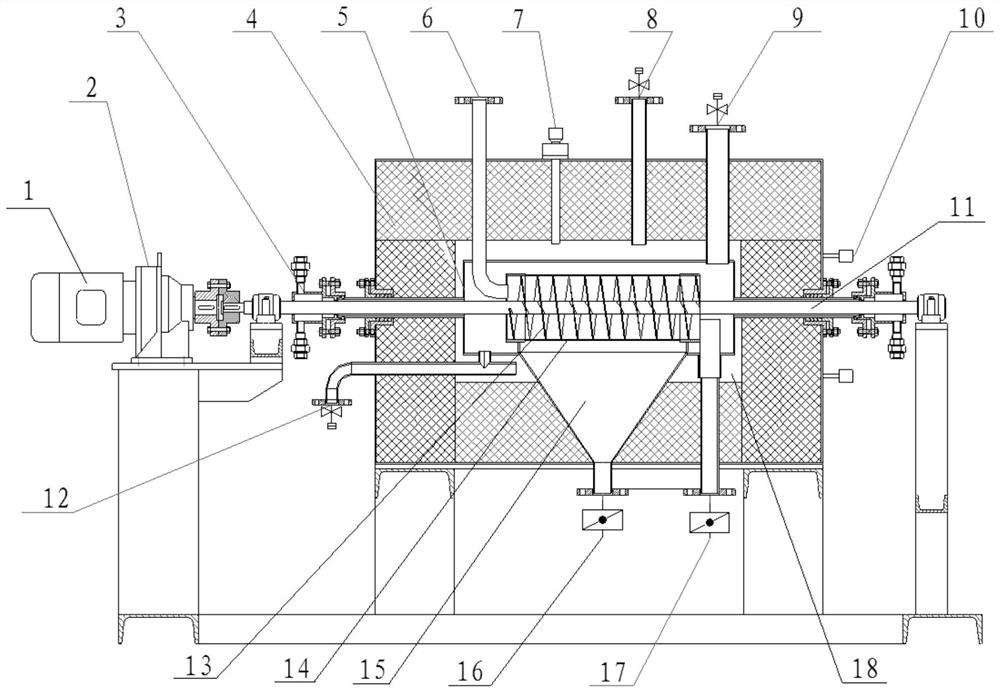

[0041] Such as figure 1As shown, the present invention provides a spent fuel short-section oxidation device, which is used to oxidize the spent fuel short section, which includes a sealed and heatable furnace body 4; The sealed protective cover 5 is arranged on the cylindrical oxidation reactor 14 in the protective cover 5 through the transmission shaft 11. The transmission shaft 11 is arranged along the central axis position of the oxidation reactor 14, and can drive the oxidation reactor 14 to rotate together. The part of the transmission shaft 11 located in the oxidation reactor 14 is provided with a helical blade 13, and the helical blade 13 is connected with the oxidation reactor 14 and the transmission shaft 11; the cylinder wall of the oxidation reactor 14 is uniformly provided with several through holes; The top of the oxidation reactor 14 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com