Double-layer cathode structure of direct methanol fuel cell for water collection and transportation

A technology of methanol fuel cell and cathode structure, which is applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., and can solve the problem of inconspicuous autonomous diffusion of liquid water, hindering the self-breathing process of passive fuel cells, and blocking the cathode air Entrance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

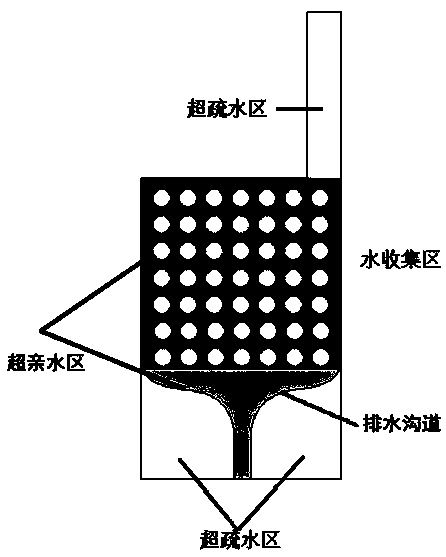

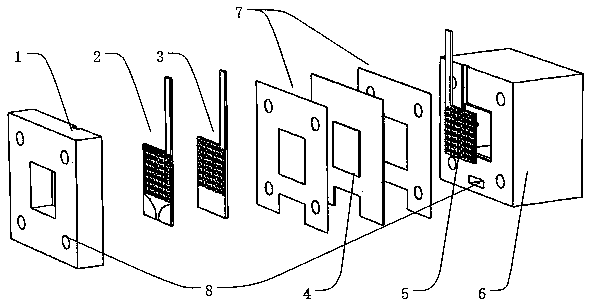

[0017] Such as figure 2 As shown, the direct methanol fuel cell double-layer cathode structure for water collection and transportation provided by the present invention includes a layer of cathode collector plate 3 and a layer of cathode water collector plate 2, wherein: the cathode collector plate 3 and The cathode catalytic layer is attached to collect current; the cathode water collecting plate 2 does not collect current, but conducts directional water transport through surface modification, and discharges cathode water to the water storage tank thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com